Safety requirements for system scaffoldingThe system scaffolding ensures the smooth progress of the construction process

Scaffolding, as an auxiliary tool for building and maintenance, plays an important role in human progress. In modern soc

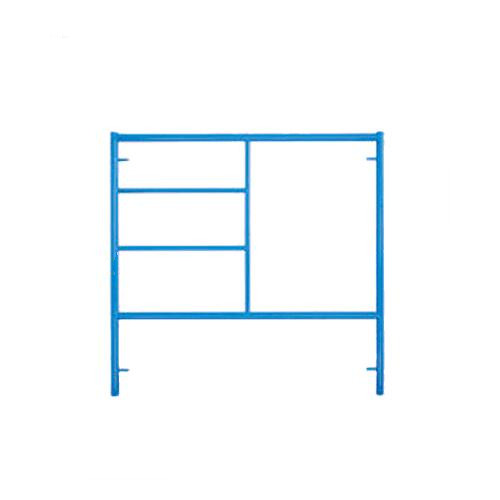

frame scaffolding has been used as a construction tool for hundreds, even thousands of years. It is used for large const

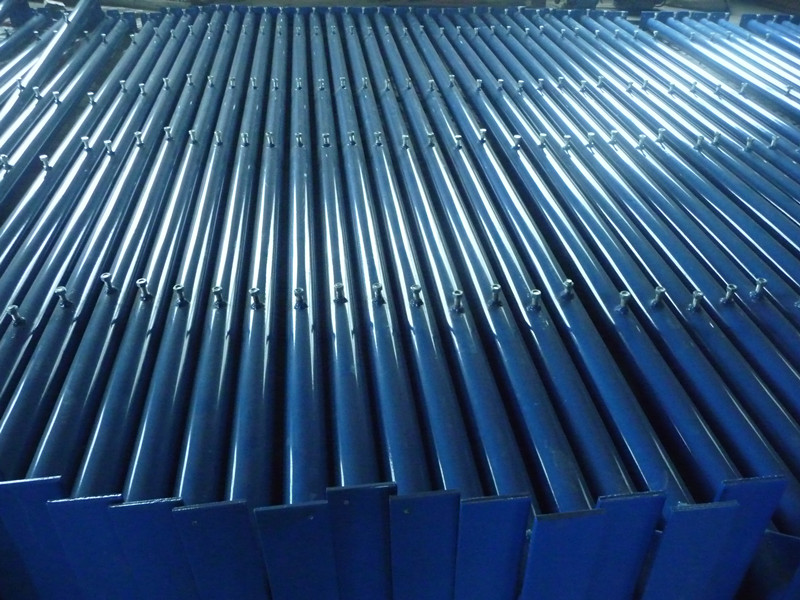

Features of scaffolding couplerscaffolding couplers, including connecting steel pipes, flat steels, hardwood wedges and

About our websiteThis website displays various ranges of scaffolding materials and metal products that we deal with. The

What are the advantages of ringlock scaffolding?Ringlock scaffolding originated in the United States and quickly became

Shop 37 Scaffolding Accessories at Northern Tool Equipment. Browse a variety of top brands in Scaffolding Accessories such as Metaltech, Qual-Craft Industries, and Peerless Hardware from the product experts. ... Outrigger for Mason Frame Scaffold Towers — 4-Pk., Model

Zinc plating or electroplating is a process where zinc is applied by using a current of electricity. It is a thinner coating than hot-dip galvanizing making it unsuitable for outdoor applications. ... now i planed to purchase the electroplated Swivel coupler for scaffolding purchase. But i want to know which is give better life

Gadsden Style 5ft x 5ft Frame with No Collar Stack Pins and 10ft Brace - Scaffolding - Sets/Frames - Gadsen Style-Orange - Scaffolding

Contribute to emjotde/forcealign development by creating an account on GitHub.

The scaffold members of steel tubing shall be complying with BS 1139 / EN 74 “Metal Scaffolding”. 75(1) Every metal tube scaffold exceeding 40 metres in height and every other scaffold ... Section 3: Specification for steel and aluminium couplers, fitting and accessories. 7. MS 1462-3-1: 2011- Metal Scaffolding – Part 3: Prefabricated ...