We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for Scaffolding Screw Jack Base,

girder Scaffolding coupler,We are also constantly looking to establish relationship with new suppliers to provide innovative and smart solution to our valued customers. The product will supply to all over the world, such as Europe, America, Australia,Mauritania, Czech republic,Auckland, Guatemala.Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services for you. We warmly welcome you to contact us and please feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today Acceptance requirements for system scaffoldingSystem scaffolding is a new type of in-line steel scaffolding with self-lo

What is Ring lock scaffolding?With the development of the times, quality, safer, more versatile materials and scaffoldin

The ringlock scaffolding is a new type of in-line steel scaffold with self-locking function. This article will introduce

Although the coupler is only one of many parts of the scaffold, it plays an important role in the safety of the scaffold

What are the advantages of ringlock scaffolding?Ringlock scaffolding originated in the United States and quickly became

Along with the development of the era, the construction industry has become one of pillar industries of our country. The

You Can find most Scaffold Standards Regulation Here:BS1139 EN 74, EN 12810, BS2482, EN 131...Buy Qualified Standard Scaffold from Wellmade

Sep 12, 2017 · The tests should cover a representation of situations including the type of anchor, the substrate material and the installer. Results should be recorded. ... Tube and coupler scaffolding higher than 33 m (measured from the ground to the highest component) generally requires additional transverse bracing (dogleg or parallel), ties and double or ...

(866) 900-0983. Fax: (252) 756-3849. Monday - Friday 8:00am - 5:00 pm. Sales Office 1705 South Evans St Greenvilles, NC 27834 Warehouse Address

Adjunct membership is for researchers employed by other institutions who collaborate with IDM Members to the extent that some of their own staff and/or postgraduate students may work within the IDM; for 3-year terms, which are renewable.

The Institute comprises 33 Full and 13 Associate Members, with 12 Affiliate Members from departments within the University of Cape Town, and 12 …

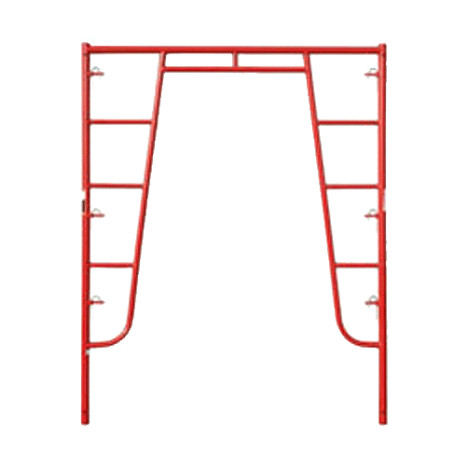

Our selection of scaffolding and accessories includes guard rails and rolling scaffolding. ... Compare Compare "UST 7' Steel Frame-Style Scaffold Diagonal Brace" with other items in your compare list. ... Compare "Guardian Fall Protection™ Steel Scaffold Side Wall Staging Bracket Guardrail" with other items on the compare list.