With the development of the times, quality, safer, more versatile materials and scaffolding designs are already available. The ringlock scaffolding is considered to be the most modern, versatile and capable scaffolding system in terms of load bearing strength. What is the ringlock scaffold? Why is it so popular?

What is a ring lockscaffold?

What are the advantages of the ringlock scaffold?

Ringlock scaffolding system

Conclusion

What is a ringlock scaffolding?

Ring lock scaffolding is one of the most popular scaffolding systems in the world. As a modular scaffolding system, it is very versatile and can be erected or suspended from the ground. Ring lock scaffolding can also be erected in a fixed or rolling tower configuration, making it ideal for high-altitude safe work.

The challenge for ring lock scaffolding is to determine the components needed to create a solution for your job site. For example, if you want to transfer high loads through scaffolding, you need to use Truss Ledgers (Double Ledgers). Similarly, if the scaffolding is to be hung or hung, it must be decided whether to use the Ring lock Lattice Girders or the large truss to erect scaffolding.

In addition, the size of the Ring lock component depends on the area you are in. For example, in North America and Australia, the Imperial Ring lock size is 7'-0" (2.13m) and 10'-0" (3.05m). Bay length. However, in South America and Europe, the available bay lengths are 6'-91⁄2" (2.07m) and 10'-1" (3.07), respectively.

What are the advantages of the ringlock scaffolding?

Ring lock scaffolding was introduced to the market long after Cuplock or Kwikstage. Ringlock is now available worldwide and is considered a flexible alternative to other system brackets on the market.

Ring locks like Cuplock and Kwikstage have their unique features and benefits, from lightweight and sturdy combinations to unique rosette central connectors that meet the extreme requirements of complex geometries.

Easy to install, great flexibility and less adaptability, making Ringlock a cost-effective option for companies and contractors.

Choose. Ring lock is powerful and flexible. Despite being a relatively new industry system, Ring locks' unique design and interlocking connections provide a unique solution to the scaffolding and construction industry, addressing the concerns of Cuplock or Kwikstage.

Strong and flexible. Ring lock can be used in a variety of industries, industries and environments, made of high-strength lightweight galvanized steel. Ring lock has the ability to be used in extreme environmental conditions at sea and at sea.

increase productivity. On industrial and building scales, ring lock offers quick installation and great flexibility. Compared to the installation of traditional pipe and fitting scaffolding, ring lock's prefabricated features allow for quick installation and increased productivity.

Unparalleled flexibility

Ring lock offers more flexibility to meet complex geometries due to its design flexibility.

Ringlock scaffolding system

The Ring lock system is ideal for structures with complex heights and shapes. Circular scaffolding is always available when angle flexibility is essential. It is designed to require minimal storage space. This versatile scaffolding system is used in the construction, offshore construction, industrial maintenance and support and entry structures of the shipbuilding industry.

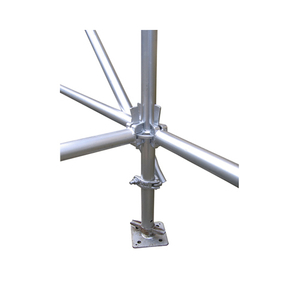

At the heart of the scaffold is a single rosette that connects the four brackets and four horizontal lines with a simple hammer. Ring lock can be used for round, curved or straight structures, as well as for mobile and stand-alone towers. The system lacks loose components, which makes it easy to use, maintain and store.

The vertical column is intended to provide vertical support for the scaffolding. It comes in many different sizes to accommodate any structure. These can be purchased with or without a faucet. Vertical columns are also known as standards.

Horizontal ledgers are designed to provide horizontal support for platforms and workloads. They can also be used as guardrails for safety reasons. They are also available in a variety of sizes to suit a variety of situations.

A diagonal bracing support is used to provide lateral support for the bracket. They can also be used as guardrails for stair systems or tension and compression members.

The rotating clamp bracket also serves as a lateral support for the bracket. In addition, it can be used as an obtuse angle guardrail in a stair system.

The truss ledger is designed to increase the strength of the scaffolding and to withstand more weight.

A screw jack or a base jack is the starting point for a circular scaffold. It is adjustable to allow for height variations when working on uneven surfaces.

Casters are used to make scaffolding towers that can roll and move from one point to another.

The buck bracket is used to create a 250 mm buck that can be attached to a skirting board or base lift.

When it is not possible to use the main bracket, the ascending bracket is used to extend the platform to get closer to the structure.

The steel plate is responsible for creating the platform on which the worker actually stands. They are placed side by side and the number of planks used determines the width of the platform.

The filler board is designed to create links between multiple work platforms. They also prevent tools and other materials from falling off the platform.

The stair rails serve as the diagonal part of the stair system and they can also serve as the connection points for the stair treads.

Storage shelves and baskets. These components add flexibility and ease of use to working on a ring stand. As you can see from the name, these can be used to keep tools and other materials in one place to make work easier.

A range of accessories can be added to the ring lock scaffolding to make it easier to use or easier to use. Some of them include:

Rosette Clamp: Used to add rosettes at any point on a vertical tube.

Davit Arm: This is a very useful component that can be used when lifting light loads with metal wheels.

Casing Adapter Clamp: Allows the connection of annular verticals at intermediate points such as truss ledgers.

Rotating Adapter Clamp: This jig can be used to attach tubes to individual garlands at various angles.

Switch pins: These pins lock the bottom and top vertical tubes together.

Conclusion

Now that you know the main components of all ring lock scaffolding, this will help you better assemble a ring lock scaffold. If you are looking for a safer, more efficient and reasonably priced high quality ring lock scaffold, Nanjing Tuopeng Construction Technology can provide you with the perfect product.