The invention of scaffolding greatly improved the convenience, speed and safety of construction. However, with regard to the key parts of the scaffolding, the knowledge of the scaffolding coupler is generally not known to the public. For example, what is the bearing capacity of the scaffolding coupler?

What is a scaffolding coupler?

Scaffolding coupler load capacity

What is the difference between the load capacity of various couplers?

Conclusion

What is a scaffolding coupler?

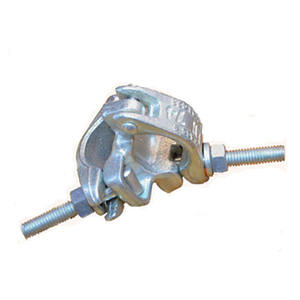

Scaffolding couplers are basically the basic components used to assemble tube and coupler scaffolding. Scaffolding couplers are mounted on the scaffolding pipes to hold the struts in place. Depending on the structural application of the required support tubes and fittings, they support the interior to the internal struts or the internal to external struts by means of fixed or rotating fittings. The coupler works by creating a straight line or an angle to ensure that the rest of the scaffold is securely held in a structurally stable position. In general, these products are rotated at a standard 90 degree angle and centered to provide additional support for the scaffolding.

Scaffolding couplers are suitable for all occasions. Whenever you connect two scaffolding tubes together, you need the right cooupler to get the job done.

Customers can easily buy couplers and accessories of different sizes and sizes and choose according to their needs.

Scaffolding coupler load capacity

Scaffolding couplers are essentially the basic components used to assemble a tubular formwork. Pipe joint scaffolding is defined as "a scaffold with a single round tube as standard, and the bracket or tie rod connected together by means of a designed coupler.

This basic accessory for connecting two scaffolding pipes can be used to create a variety of scaffolding structures or as an attachment to a prefabricated scaffolding system.

What is the difference between the load capacity of various couplers?

1.Double coupler load capacity:

Connect two tubes with an outer diameter of 48.3 mm at a right angle.

The fastening nut is suitable for standard scaffolding wrenches (23 mm A/F).

Replaceable "T" bolts, nuts and washers.

Rugged design from drop forged steel or pressed steel for durability and reliability.

· Hot dip galvanizing treatment, corrosion resistant.

· Typical working load limit is 625Kn (by weight) 63732KGS)

The slip resistance is at a tightening torque of 54 nm.

Can be used to resist tension or compressive loads.

CLICK here to view our EN74 certificate for double coupler.

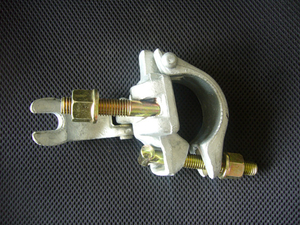

2. Swivel coupler load capacity

Attach scaffolding tubes with an outer diameter of 48.3 mm at any angles.

Each half of the coupler is coupled to the shaft.

Generally used to connect support members. Also used for tension splicing of falsework tubes.

The fastening nut is suitable for standard scaffolding wrenches (23 mm A/F).

Replaceable "T" bolts, nuts and washers.

Rugged design from drop forged steel or pressed steel for durability and reliability.

CLICK here to view our EN74 certificate for swivel coupler.

3. Expenditure joint coupler load capacity

Connect the 48-diameter outer diameter falsework tube to the standard end-to-end interior.

Installed in the scaffolding tube.

When the bolt is tightened, the inner diameter of the stent tube is extended to feet.

Fastening bolts for standard falsework wrenches (23 mm AF)

Made of forged steel.

· Hot dip galvanizing treatment.

The pin can withstand the full load carrying capacity of the scaffold tube under compressive loads.

Do not use for tension loads. Under tensile loading, it must be connected to another falsework tube and rotary coupler (required tension load check).

This type of joint pin must only be used to connect scaffolding tubes with the same inner diameter and the same wall thickness.

4. External scaffolding coupler load capacity

Connect the 48mm outer falsework tube ends to the outside.

Standard end connection for falsework tubes.

Located on the outer diameter of the scaffold tube member.

The fastening bolts are suitable for standard falsework wrenches.

Made of high quality steel.

· Hot dip galvanizing treatment.

Under the compressive load, the coupler can withstand the full load capacity of the scaffold tube.

Do not use for tension loads. Under tensile loading, it must be connected to another falsework tube and rotary coupler (required tension load check).

This type of coupler must only be used to connect bracket tubes of the same outer diameter.

5. Put log coupler load capacity

• Connect 48 diameter scaffold tubes at right angles.

• Used to secure the log tube to the sorting tube.

The fastening nut is suitable for standard falsework wrenches (23 mm A/F).

Replaceable "T" bolts, nuts and washers.

Stamped steel floating roof and forged steel cap.

Hot dip galvanized, corrosion resistant.

Usually used to secure guardrails and intermediate railings at right angles to the standard. Other uses may distort the coupler, making tube retention ineffective and not suitable for use.

Cannot be used to connect a log pipe to a pipe scaffold.

Only right angle couplers can be used for this purpose.

WL=0.62kN (632224KGF) non-slip tube through faps coupler

The tightening torque is 54 nm.

Conclusion

One of the most important parts of the falsework is the foot pedal clutch, so you need to choose a foot pedal clutch with sufficient capacity. Before purchasing a scaffolding cooupler, it must be thoroughly tested and verified. If you need durable, reliable and cheap scaffolding connectors, Nanjing Tuopeng Construction Technology Co., Ltd. can provide ideal products.