Mason frame scaffolding is a common scaffold used primarily in the Spanish and South American markets. The importance of scaffolding has been well known to the public, but it is clear that Mason frame scaffolding, even if it plays an important role in architecture, is not understood. For example, how high is a section of Mason frame scaffolding?

What are the characteristics of Mason scaffolding?

What are the advantages of the frame scaffolding system?

How high is the mason frame scaffolding section?

What should be the frequency of checking the scaffolding?

Conclusion

What are the characteristics of mason frame scaffolding?

Masonry scaffolding or masonry frame scaffolding is a common industry term referring to our popular frames and supporting scaffolding. This is the most common type of scaffolding used by all types of contractors to make bricks or blocks safer and more efficient, from carpenters and masons to the owners of his weekend projects. It is easy to install and remove, allowing you to reach the required height quickly.

Usually, mason frame scaffolding is used for stone work. They are usually used by one or two layers of residential contractors, painters, etc., but their modular framework can also be stacked several times for large construction projects. In mason frame scaffolding, there are two standard frames with a distance of 1.5 meters from the first standard. Mason frame scaffolding is completely independent of the stone wall.

The mason frame scaffolding is used to carry heavy loads because the load on the stones is very heavy. Therefore, the mason frame scaffolding is made stronger by placing the standards at fairly close distances.

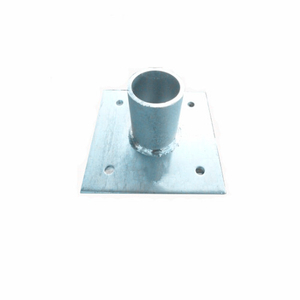

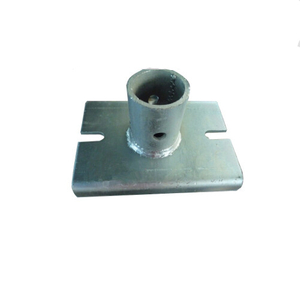

1. The Mason frame scaffolding consists of two ladder frames, two pairs of crossbars and four connecting pins.

2. Frame scaffolding is easy to assemble and disassemble, saving you labor and time.

3. Workers can climb the ladder smoothly and safely without the need for additional ladders.

4. Trapezoidal Mason frame scaffolding is especially suitable for masonry wall construction, exterior wall painting or plaster work. It is easy to operate and moves with casters.

What are the advantages of the frame scaffolding system?

Frame scaffolding is probably the most commonly used scaffolding system in the construction industry and the main product of all scaffold system suppliers. It has been used for decades and is still used in large or small construction projects. The popularity of frame scaffolding systems in Malaysia and around the world stems from several advantages.

In construction projects, time is money. The simplicity of the frame scaffolding system makes it easy to assemble and saves a lot of time during installation and disassembly. This further saves costs because the scaffold system typically comes from scaffold suppliers.

Safety. The frame scaffolding system is made of high-strength steel pipe and heavy-duty rating, so it performs well in terms of safety. The safety and robustness of frame scaffolding is further enhanced by its simple nature, allowing workers to worry about their safety with less work.

Versatility. The frame scaffolding system is available in a variety of lock types and tube sizes for a variety of masonry structures, maintenance and support work. The availability of Mason scaffolding, ladders, drills and pedestrian canopy frames allows for more scaffolding rental options, allowing the scaffold system to be used in almost any area and corner.

How high is the mason frame scaffolding section?

The height of the mason frame scaffolding is not strictly limited according to national standards, but there is a set of specifications for the height of the scaffold. When the regular scaffolding manufacturers set the scaffolding price in the factory, there will be a factory inspection report, which has different inspection requirements for the use of more mobile scaffolding and export scaffolding that is used abroad.

The foundation of the scaffold column should meet the requirements of the program.

1.When the height is less than or equal to 25 meters, it can be tamped and laid with 5 cm thick wood. When the length is 2 meters, it is placed perpendicular to the wall. When the length is greater than 3m, it should be placed parallel to the wall.

2 When the construction height is 25-50m, the basic method should be designed according to the site durability or backfilling. The sleeper can be used to support the cushion, or the 20cm thick ballast can be laid on the concrete slab. E laying, 12-16 channel steel laying.

3. When the erection height exceeds 50m, calculation should be carried out. The foundation design should be based on the durability method, or the ash foundation should be used below 1m below the ground, or the concrete foundation of 50m thick should be poured, and the pillow should be used.

When the pole is not buried, when the ground is 20cm away, the setting of the pole and the crossbar is the same as that of the large crossbar, and there is no need to set the crossbar. Its role is to fix the bottom of the pole to suppress horizontal position and sink.

The wooden scaffold is buried and there is no need to sweep the floor. The depth is 30-50cm. The bottom of the pit should be smashed with broken bricks, and the backfill in the pit should be layered and compacted.

The foundation of the scaffolding is low, and no drainage measures should be considered. After the wooden scaffold is buried, the backfill should be kept above the ground to prevent the bottom water.

What should be the frequency of checking the scaffolding?

A: All erected scaffold (except for scaffolding) is inspected by the scaffold supervisor at least once every seven days, if a person is likely to fall more than 2 meters from any part of the scaffold. All metal brackets are over 30 m high and/or need to be inspected for cantilever or cantilever support. Safes certified for use by professional engineers Complete scaffold construction, then at least once every three months

Conclusion

Mason frame scaffolding is easy to assemble and disassemble for sturdy use. However, you still can't take care of scaffold construction safely, make sure you buy a standard, precision-tested scaffold. If you are looking for durable, sturdy, reasonably priced high quality mason frame scaffolding, Nanjing Tuopeng Construction Technology can provide you with the perfect product.