Scaffolding is often an essential part of building and home maintenance, and negligence in erecting scaffold can lead to serious accidents. We all know that the mason frame scaffolding is easy to install and disassemble, but is it really safe?

What is the stonemason frame scaffolding?

Is the mason frame scaffolding safe?

How to properly install the mason frame scaffolding?

Construction, installation, maintenance, repair and dismantling of scaffolding

Conclusion

What is the stonemason frame scaffolding?

Mason frame scaffolding is a common industry term referring to our popular frame and support scaffolding. All types of contractors, from carpenters and masons to weekend project owners, use the most common scaffolding to make bricks or bricks safer and more efficient. It is easy to install and remove, allowing you to reach the required height quickly.

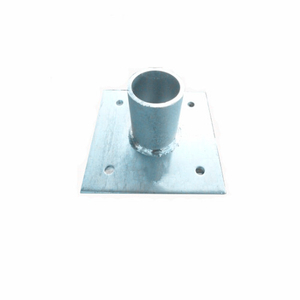

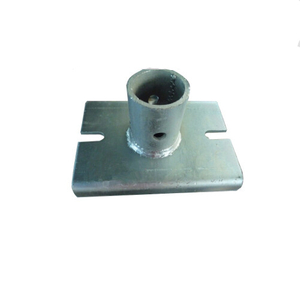

Masonry frame scaffolding is generally used for masonry. mason frame scaffolding consists of two ladders, two pairs of crossbars and four connecting pins. They are usually used by one or two-story residential contractors, painters, etc., but their modular framework can also be used in large construction projects. Stacked many times. In the masonry frame scaffolding, there are two standard frames, 1.5 m from the first standard. The masonry frame scaffolding is

completely independent of the stone wall.

Is the mason frame scaffolding safe?

Masonry frame scaffolding is used to carry heavy objects because the weight on the stone is heavy. Therefore, by placing the standard at a fairly close distance, the stonemason frame scaffolding becomes stronger.

In addition to solid safety, masonry frame scaffolding has other advantages

Frame scaffolding is easy to install and remove, saving time and energy.

Workers can climb the ladder smoothly and safely without the need for additional ladders.

The trapezoidal masonry frame scaffolding is especially suitable for brick structures, exterior wall paints or plastering works. It is easy to operate and can be moved with the casters.

How to properly install the mason frame scaffolding?

Choose the security foundation to build and set up the scaffolding. Obtain a mud plate or bottom plate to secure the scaffolding to make the foundation more stable. One of the main problems here is the basis for the level and safety of scaffolding. If you are on an uneven ground, I need to dig to make dirt at any high corner. In addition, use the adjustment screws on the scaffolding to level the structure. If the surface is on a sharp slope, get a leg stretch.

Select the casters. If you plan to move the scaffolding to various locations, include casters in the scaffold setup. Remember to lock the casters when you put it in place.

Assemble the scaffolding frame. Arrange the end of the scaffold. Lift an end piece and connect the upper beam. When you lift the second end piece and attach its upper beam, the distal end of the support should support the end piece. Secure the ends of the cross braces to the bottom of the opposite end frame.

Make sure the scaffolding is stable. Move the scaffold to the desired location and make sure it is level and strong.

Place the board. Lift the plank through the scaffolding bar and seat it. Hardware should be included to hold the board in place.

Enter the scaffold safely. If using a ladder to enter the scaffolding, use scaffold designed for the scaffolding. Staircase ladders can be used to enter the scaffold, but must have handrails and pedals. One problem with access points is to make the operation safe and prevent the scaffold from tipping over.

Connect the guardrail. Due to the height of the equipment and the risk of falling, it is highly recommended that all scaffolds use guardrails. Also consider the use of cable ties and other fall arresters.

Check the scaffold for safety. Thoroughly check the scaffold settings to make sure all parts are safe. Re-examine the scaffolding system and return to the site each time you leave the site to ensure it is still safe.

Construction, installation, maintenance, repair and dismantling of scaffolding

It is the responsibility of the occupants of the workplace to build, erect or install scaffold on or under construction.

Partially constructed, erected, installed or removed scaffolding or parts thereof shall not be used unless safe.

If any scaffold is unsafe to use, an obvious warning notice or sign shall be issued in a form that is easily understood by all, indicating that the scaffold or part thereof is not to be used and that it must be placed anywhere, depending on the circumstances, the scaffold or parts may Being approached for use.

Each scaffold shall be properly maintained and each part shall be fixed, fixed or placed to prevent any accidental displacement, to the extent reasonably practicable.

Any damaged or weakened scaffold and any components or components thereof shall be repaired as soon as reasonably practicable.

No one shall be allowed to enter a damaged or damaged scaffold except for the scaffolding erector who is repairing the scaffold.

All reasonable and practicable measures shall be taken to ensure the safety of the person performing the repairs described.

If the attachment of the scaffold to the permanent structure must be removed, the appropriate removal of the scaffolding portion of the fitting should be removed unless appropriate measures are taken to ensure the stability of the scaffold.

Conclusion

The mason frame scaffolding is very sturdy at the same time, so you can make sure it is safe, but more importantly, you have mastered the proper installation and use of scaffold. If you need a well-tested, sturdy, high quality mason frame scaffolding, Nanjing Tuopeng Construction Technology can provide you with the perfect product.