Content Menu

● Key Features That Accelerate Assembly

>> Minimal Components

>> Lightweight Construction

>> Tool-Free, Hook-On Connections

>> Modular and Adaptable Design

>> Advanced Guard Rail (AGR) System

>> Pre-Assembled Units

● Step-by-Step Assembly Guide

>> 1. Site Preparation

>> 2. Base Assembly

>> 3. Deck and Platform Installation

>> 4. Guardrails and Toeboards

>> 5. Access Solutions

>> 6. Bracing and Anchoring

>> 7. Final Safety Checks

● Real-World Case Studies

>> Shanghai Tower Facade Maintenance

>> Offshore Oil Platform

>> Urban Infrastructure Project

● Safety, Compliance, and Maintenance

>> Load Capacity and Stability

>> Collective Protection

>> Maintenance Protocol

>> Damage Assessment

● Environmental Impact and Sustainability

>> Reduced Carbon Footprint

>> Longevity

● Future Developments in HAKI Universal

>> Smart Scaffolding

>> Material Innovations

● Conclusion

● FAQ

>> 1. How many people are needed to assemble the HAKI Universal Scaffolding System?

>> 2. What types of projects is the HAKI Universal system suitable for?

>> 3. What is the maximum bay length and height for HAKI Universal scaffolding?

>> 4. Is the HAKI Universal system compatible with other scaffolding brands?

>> 5. What certifications and safety standards does the HAKI Universal system meet?

The HAKI Universal Scaffolding System is a modular, high-strength system designed for rapid assembly and maximum safety. It is used worldwide in construction, industrial maintenance, infrastructure, and energy sectors. Its unique design allows for tool-free assembly, minimal component count, and adaptability to complex structures such as curved facades, suspended platforms, and confined spaces.

Key Features That Accelerate Assembly

Minimal Components

The HAKI Universal system requires only 7–10 core components for most builds:

- Standards

- Ledgers

- Transoms

- Decks

- Guardrails

- Base Jacks

- Connectors

This simplicity means less time sorting and handling parts.

Lightweight Construction

Components are up to 35% lighter than traditional tube-and-fitting scaffolding, reducing fatigue and enabling faster manual handling.

Tool-Free, Hook-On Connections

The patented “hook-on” locking-catch system allows components to be secured in seconds without tools. This innovation alone can reduce assembly time by up to 60%.

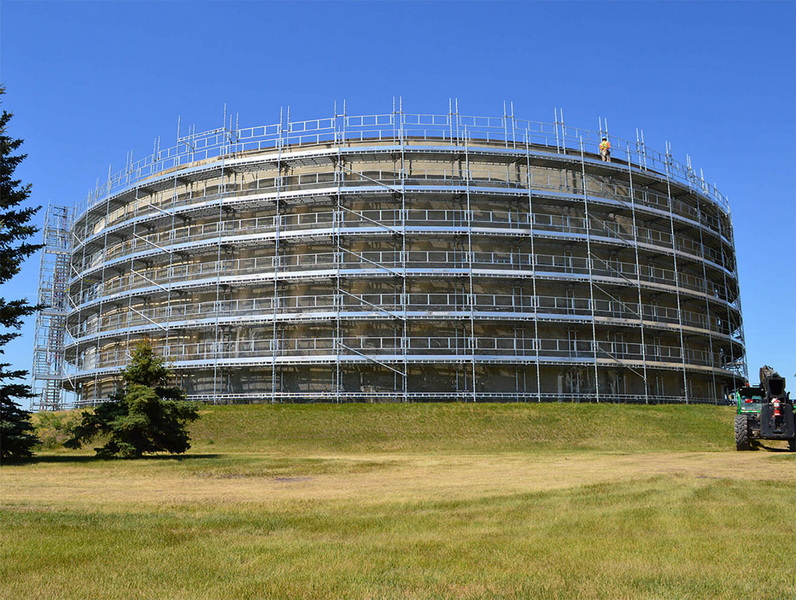

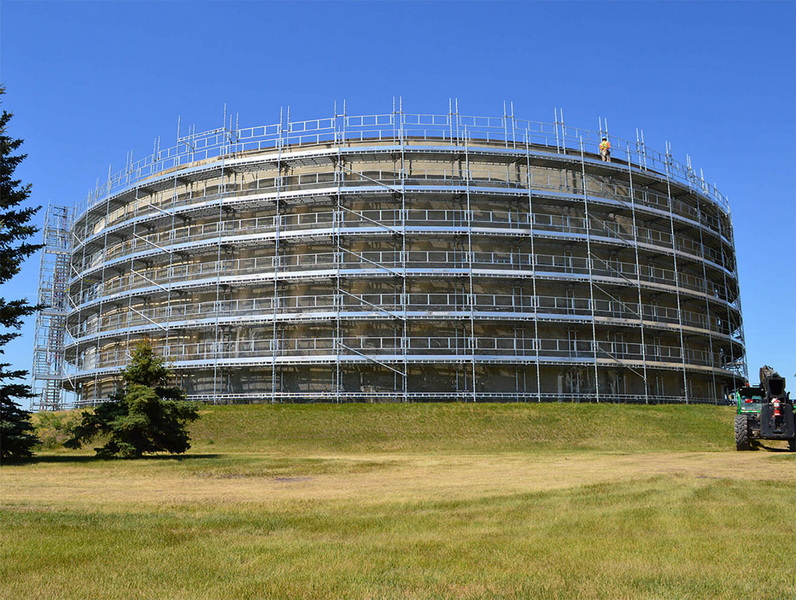

Modular and Adaptable Design

The system can be configured for straight, circular, or irregular structures and can be reconfigured quickly to adapt to changing project requirements.

Advanced Guard Rail (AGR) System

The AGR system provides collective protection throughout the assembly process, ensuring that workers are always protected from falls.

Pre-Assembled Units

Stair towers and access platforms can be pre-assembled on the ground and lifted into place, saving significant time at height.

Step-by-Step Assembly Guide

1. Site Preparation

- Level the ground and clear debris.

- Lay out base jacks and standards according to the scaffold plan.

2. Base Assembly

- Install standards (upright tubes) at the corners.

- Attach ledgers and transoms using the hook-on system to form the scaffold's base frame.

3. Deck and Platform Installation

- Place steel or aluminum decks onto the ledgers.

- Secure decks with integrated locking mechanisms.

4. Guardrails and Toeboards

- Attach guardrails and toeboards for collective fall protection.

- All components are color-coded for quick identification.

5. Access Solutions

- Install stair towers or ladders.

- HAKI staircases require only 7 components per level, compared to 23 in traditional systems.

6. Bracing and Anchoring

- Add diagonal bracing for stability.

- Anchor the scaffold to the structure as required by regulations.

7. Final Safety Checks

- Inspect all connections and locking mechanisms.

- Verify compliance with load and safety standards.

Real-World Case Studies

Shanghai Tower Facade Maintenance

- Challenge: Curved, twisting facade at 632 meters.

- Solution: HAKI Universal with 1655mm wide bays, pre-assembled stair towers.

- Outcome: 2,150 bays erected in 18 days; 4.2 meters/day progress; zero safety incidents.

Offshore Oil Platform

- Challenge: Limited assembly window due to tides.

- Solution: Saltwater-resistant galvanized HAKI Universal system.

- Outcome: 6-hour scaffold installation during 8-hour low-tide window; withstood 9.3m/s winds.

Urban Infrastructure Project

- Challenge: Confined space, high pedestrian traffic.

- Solution: HAKI Universal's compact, modular design allowed safe, rapid assembly with minimal street closure.

- Outcome: 60% reduction in assembly time; project completed ahead of schedule.

Safety, Compliance, and Maintenance

Load Capacity and Stability

- Certified up to Load Class 6 (6.0 kN/m²) according to EN 12810 and EN 12811.

- Advanced bracing and locking mechanisms ensure stability under heavy loads.

Collective Protection

- The AGR system provides continuous edge protection during assembly.

- All platforms and stairways include integrated toeboards and guardrails.

Maintenance Protocol

- After Each Use: Freshwater rinse, visual inspection.

- Biannual: Zinc spray touch-up, bolt and weld check.

- Annual: Full component thickness testing, replacement of worn parts.

Damage Assessment

- Class 1: Cosmetic scratches, no action needed.

- Class 2: Minor dents, reinforce locally.

- Class 3: Cracks or warping, replace immediately.

Environmental Impact and Sustainability

Reduced Carbon Footprint

- Production: 28% lower CO₂ emissions due to recycled materials.

- Transport: 40% fewer shipments thanks to compact, lightweight components.

- Onsite: 65% less energy use due to faster assembly and reduced equipment runtime.

Longevity

- Properly maintained HAKI Universal components last 12–15 years.

- Corrosion-resistant coatings ensure durability in harsh environments.

Future Developments in HAKI Universal

Smart Scaffolding

- RFID Tracking: Monitors component usage and location.

- IoT Sensors: Real-time load and stability monitoring.

- AR Assembly Guides: Augmented reality instructions for faster, error-free assembly.

Material Innovations

- Graphene Coatings: Targeting further weight reduction and increased durability.

- Self-Healing Finishes: Microcapsule technology for automatic corrosion repair.

Conclusion

The HAKI Universal Scaffolding System redefines speed and safety in construction. Its minimal, lightweight components, tool-free assembly, and advanced safety features allow teams to build up to 60% faster than traditional systems. Whether for high-rise towers, offshore platforms, or urban projects, HAKI Universal delivers unmatched efficiency, adaptability, and compliance with the highest safety standards. As construction demands evolve, HAKI continues to innovate, ensuring its system remains at the forefront of scaffolding technology.

FAQ

1. How many people are needed to assemble the HAKI Universal Scaffolding System?

A typical crew of 2–4 trained workers can assemble large sections quickly and safely, thanks to the lightweight, modular components and hook-on connections.

2. What types of projects is the HAKI Universal system suitable for?

It is ideal for construction, industrial maintenance, infrastructure, offshore, and energy projects, including complex curved or suspended structures.

3. What is the maximum bay length and height for HAKI Universal scaffolding?

Standard bay lengths are up to 3.05 meters, with bay widths from 700mm to 1655mm. There is no technical height limit; the system has been used on structures over 800 meters tall.

4. Is the HAKI Universal system compatible with other scaffolding brands?

No. For safety and compliance, HAKI Universal components should only be used with other HAKI products.

5. What certifications and safety standards does the HAKI Universal system meet?

HAKI Universal is certified to EN 12810 and EN 12811, up to Load Class 6 (6.0 kN/m²), with full traceability and quality assurance.