Content Menu

● Introduction to Ringlock Scaffolding

● Core Components of Ringlock Scaffolding

>> Vertical Standards (Uprights)

>> Horizontal Ledgers

>> Diagonal Braces

>> Ring Nodes (Rosettes)

>> Base Jacks and Base Collars

>> Steel Platforms and Planks

>> Brackets and Special Components

● Accessories and Additional Components

>> Stair Units and Stair Beams

>> Guardrails and Toe Boards

>> Clamps and Connectors

>> Davit Arms and Load Handling Accessories

● Material and Surface Treatment

● Advantages of Ringlock Scaffolding Components

● Maintenance and Inspection

● Conclusion

● FAQ

>> 1. What are the main components of Ringlock scaffolding?

>> 2. How do ring nodes (rosettes) enhance the scaffolding system?

>> 3. What materials are Ringlock scaffolding components made of?

>> 4. Can Ringlock scaffolding be adapted for curved or irregular structures?

>> 5. What accessories improve safety on Ringlock scaffolding?

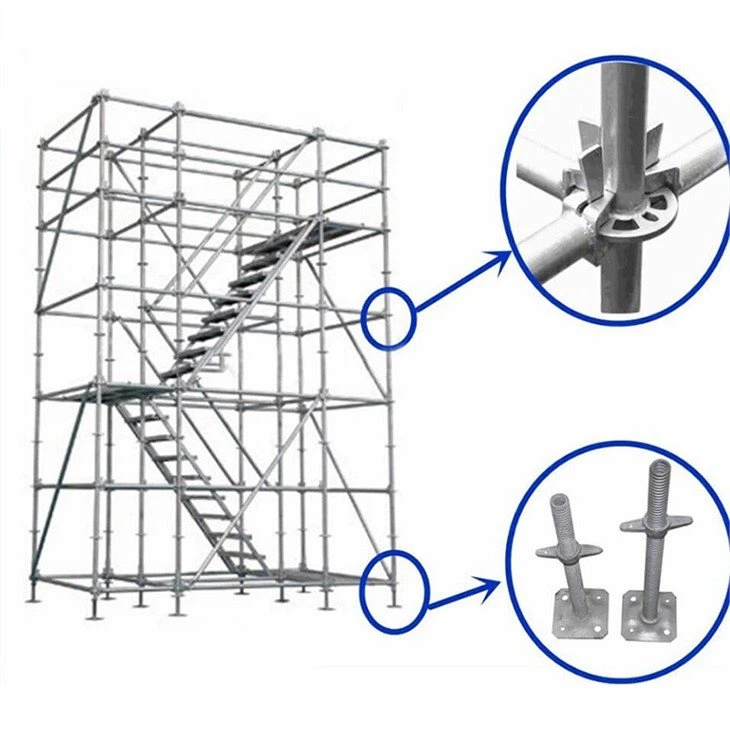

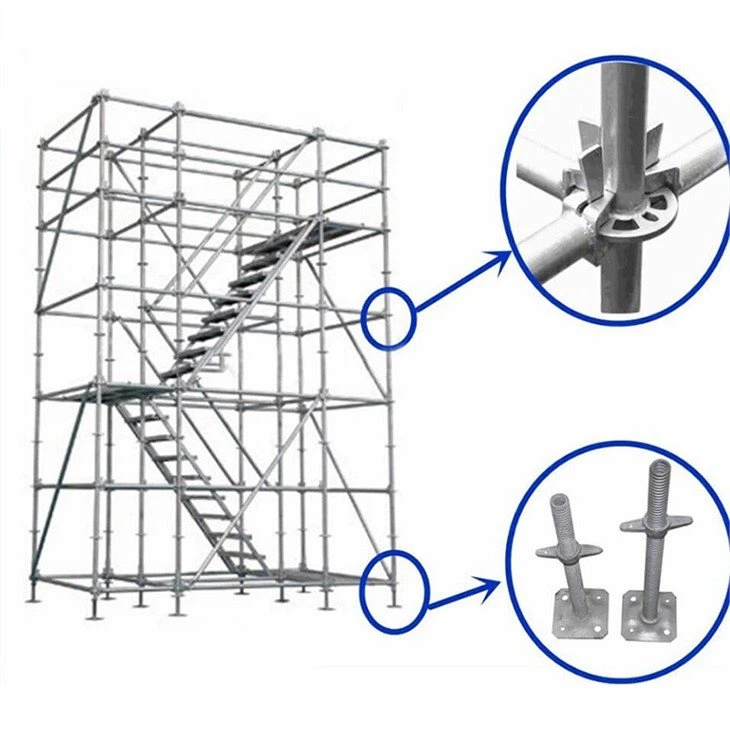

Ringlock scaffolding is one of the most versatile and widely used scaffolding systems in construction and industrial projects worldwide. Its modular design, ease of assembly, and robust load-bearing capacity make it a preferred choice for scaffolding towers, bridges, offshore platforms, and many other applications. This comprehensive guide explores the essential components and accessories of Ringlock scaffolding, explaining their functions, features, and how they contribute to the overall system's efficiency and safety.

Introduction to Ringlock Scaffolding

Ringlock scaffolding is a modular system based on a unique ring node (rosette) design that allows multiple horizontal and diagonal components to be connected securely to vertical standards. This design enables fast assembly and disassembly, high structural stability, and adaptability to complex geometries such as curves and irregular shapes.

The system is widely used in construction, industrial maintenance, offshore platforms, and infrastructure projects due to its strength, safety, and flexibility.

Core Components of Ringlock Scaffolding

Vertical Standards (Uprights)

Vertical standards, also called uprights, form the backbone of the Ringlock scaffolding system. They are hollow steel tubes with ring nodes (rosettes) welded at regular intervals, typically every 500mm. These rosettes serve as connection points for horizontal ledgers, diagonal braces, and other components.

- Sizes: Vertical standards come in various lengths, commonly ranging from 500mm to 3000mm or more, to accommodate different scaffold heights.

- Function: Provide vertical support and carry the load of the scaffold structure.

- Connection: The ring nodes allow multiple connections at different angles (up to eight directions), ensuring flexibility.

Horizontal Ledgers

Horizontal ledgers connect the vertical standards horizontally, providing lateral support and forming the scaffold's framework for working platforms.

- Design: Ledgers have cast steel ends with wedge pins that lock firmly into the ring nodes.

- Sizes: Available in lengths from 300mm up to 3000mm or more.

- Function: Support platforms and distribute loads horizontally.

- Safety: Can also serve as guardrails when installed at appropriate heights.

Diagonal Braces

Diagonal braces provide essential lateral stability to the scaffold, preventing sway and enhancing rigidity.

- Connection: Similar to ledgers, diagonal braces use wedge pins to lock into ring nodes at an angle.

- Lengths: Available in various lengths to suit different scaffold configurations.

- Use: Often installed in a cross-bracing pattern on scaffold bays.

- Additional Role: Can be used as guardrails in stair systems or tension/compression members.

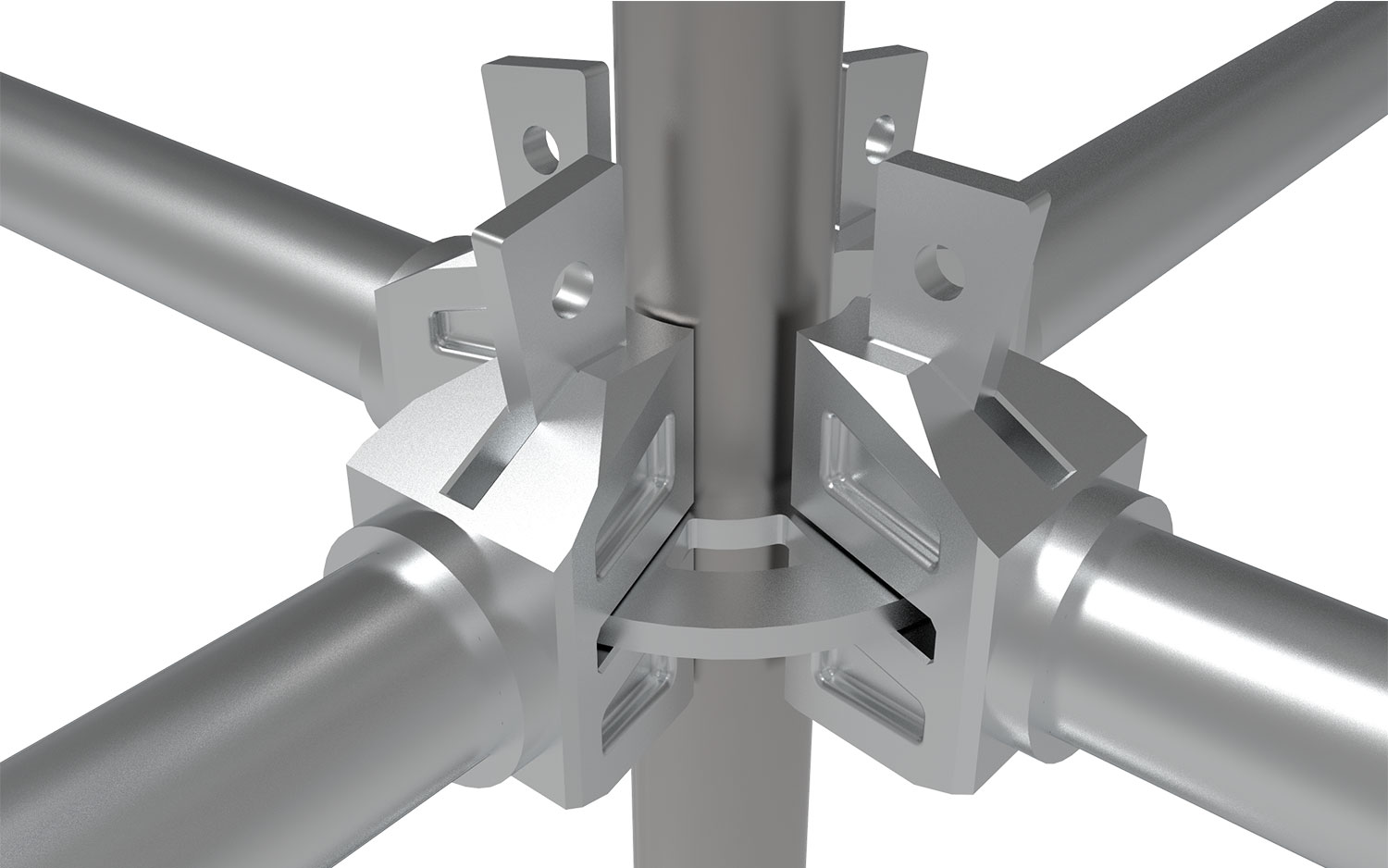

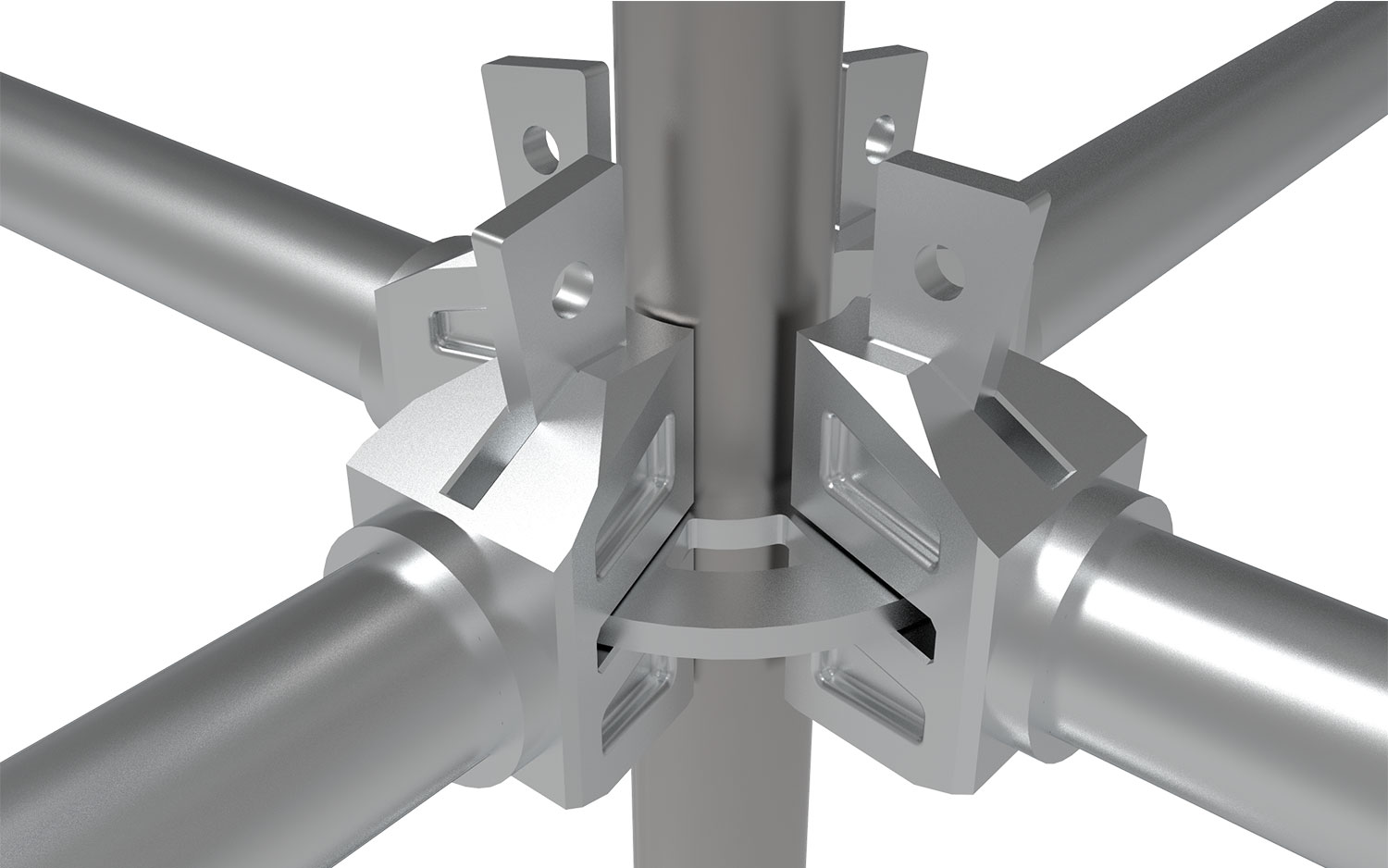

Ring Nodes (Rosettes)

The ring node or rosette is the heart of the Ringlock scaffolding system.

- Shape: Circular steel plate welded to vertical standards.

- Function: Allows up to eight connections (four horizontal and four diagonal) at various angles.

- Advantages: Enables fast, secure, and versatile connections without loose parts.

- Variations: Different regional standards exist (e.g., Layher Allround, Pin Lock), but the principle remains the same.

Base Jacks and Base Collars

Base jacks and collars provide the foundation and height adjustment for the scaffold.

- Base Jack: Adjustable screw jacks that compensate for uneven ground, ensuring the scaffold is level.

- Base Collar: Fixed collar placed over the base jack to stabilize the first vertical standard.

- Materials: Usually made of steel with hot-dip galvanized or electro-galvanized finishes for corrosion resistance.

Steel Platforms and Planks

Steel platforms form the working surface on scaffolds.

- Design: Steel planks with welded hooks on corners for secure attachment to ledgers.

- Sizes: Common lengths include 1500mm, 1800mm, 2400mm, with widths typically around 240mm to 500mm.

- Features: Perforated surfaces for anti-slip properties; multiple beams welded underneath for strength.

- Infill Planks: Used to fill gaps between platforms, preventing tools or materials from falling.

Brackets and Special Components

- Brackets: Used to extend the platform or create step-downs in elevation.

- Cross Braces: Provide additional stiffness and can double as guardrails.

- Step-Down Brackets: Allow for platform height changes, useful in uneven terrain or stair systems.

- Hop-Up Brackets: Extend platforms closer to the structure when the main scaffold cannot be positioned near enough.

Accessories and Additional Components

Stair Units and Stair Beams

- Stair Beams: Horizontal members designed to support stair treads.

- Stair Units: Pre-fabricated stair sections that provide safe, easy access between scaffold levels.

- Guardrails: Integrated into stair units for fall protection.

Guardrails and Toe Boards

- Guardrails: Installed on open sides of platforms to prevent falls.

- Toe Boards: Placed along platform edges to prevent tools and materials from falling off.

- Materials: Typically steel or aluminum, designed to fit securely into ledger or bracket connections.

Clamps and Connectors

- Rosette Clamps: Attach ring nodes at any point on vertical tubes for added flexibility.

- Spigot Adapter Clamps: Connect verticals at intermediate points.

- Swivel Adapter Clamps: Allow tubes to be connected at various angles.

- Toggle Pins: Secure vertical tubes together, ensuring stability.

Davit Arms and Load Handling Accessories

- Davit Arms: Used for lifting light loads with gin wheels, attached securely to scaffolding.

- Load Handling: Accessories that facilitate material movement and improve site efficiency.

Material and Surface Treatment

- Material: Most components are made of high-quality steel such as Q235 or Q345, offering excellent strength and durability.

- Surface Treatment: Hot-dip galvanization or electro-galvanization is commonly applied to resist corrosion and extend service life, especially in harsh environments like offshore or industrial sites.

Advantages of Ringlock Scaffolding Components

- Modularity: Fewer parts mean faster assembly and dismantling.

- Flexibility: Multiple connection points allow complex scaffold geometries.

- Safety: Secure locking mechanisms reduce risk of loose components.

- Load Capacity: High strength steel supports heavy loads safely.

- Durability: Galvanized surfaces resist corrosion, extending lifespan.

- Reusability: Components can be reused across multiple projects, reducing waste.

Maintenance and Inspection

Proper maintenance and regular inspection of Ringlock scaffolding components are essential to ensure safety and prolong the system's lifespan.

- Routine Inspections: Conduct daily visual checks for damage, wear, or corrosion.

- Connection Checks: Verify that all wedge pins, locking mechanisms, and clamps are secure.

- Cleaning: Remove dirt, grease, or debris that may interfere with component connections.

- Repair and Replacement: Replace any damaged or worn components immediately to maintain structural integrity.

- Documentation: Keep detailed records of inspections and maintenance activities.

Conclusion

Understanding the components and accessories of Ringlock scaffolding is essential for safe and efficient scaffold assembly and use. Each part, from vertical standards to davit arms, plays a critical role in the system's overall performance. The modular design and secure locking mechanisms allow for rapid setup, adaptability to complex structures, and enhanced safety on site. Proper maintenance and inspection of these components ensure long-term durability and reliability. By mastering the details of each component, construction professionals can optimize scaffold use, improve site productivity, and uphold the highest safety standards.

FAQ

1. What are the main components of Ringlock scaffolding?

The main components include vertical standards with ring nodes, horizontal ledgers, diagonal braces, base jacks and collars, steel platforms, brackets, and various clamps and connectors.

2. How do ring nodes (rosettes) enhance the scaffolding system?

Ring nodes allow multiple components to connect securely at various angles, enabling flexibility in scaffold design and ensuring strong, stable connections without loose parts.

3. What materials are Ringlock scaffolding components made of?

Typically, high-strength steel such as Q235 or Q345 is used, with hot-dip galvanization or electro-galvanization for corrosion resistance.

4. Can Ringlock scaffolding be adapted for curved or irregular structures?

Yes, the multiple connection points on ring nodes allow for flexible angles, making it suitable for curved, circular, or irregular scaffolding configurations.

5. What accessories improve safety on Ringlock scaffolding?

Guardrails, toe boards, stair units, safety harness attachment points, and toe boards all contribute to worker safety on Ringlock scaffolding.