Content Menu

● What Is Ringlock Scaffolding?

● Key Features of Ringlock Scaffolding

● What Is Cuplock Scaffolding?

>> Key Features of Cuplock Scaffolding

● Core Differences Between Ringlock and Cuplock Scaffolding

● Detailed Comparison: Features, Safety, and Performance

>> 1. Locking Mechanism and Flexibility

>> 2. Assembly and Disassembly Speed

>> 3. Load-Bearing Capacity and Stability

>> 4. Safety Features

>> 5. Durability and Maintenance

● Applications: Where Each System Excels

>> Ringlock Scaffolding

>> Cuplock Scaffolding

● Cost Considerations and Long-Term Value

● Innovations and Trends in Modular Scaffolding

>> Ringlock Scaffolding

>> Cuplock Scaffolding

● How to Choose the Right System for Your Project

● Conclusion

● FAQ

>> 1. What is the main difference between ringlock scaffolding and cuplock scaffolding?

>> 2. Which system is safer: ringlock or cuplock scaffolding?

>> 3. Is ringlock scaffolding more expensive than cuplock scaffolding?

>> 4. Can both systems be used for high-rise or heavy-duty projects?

>> 5. How do I choose between ringlock and cuplock scaffolding for my project?

Selecting the right scaffolding system is a critical decision for any construction project. Ringlock scaffolding and cuplock scaffolding are two of the most widely used modular systems globally, each with distinct features, advantages, and ideal applications. This comprehensive guide provides an in-depth comparison between ringlock and cuplock scaffolding, covering their design, safety, efficiency, adaptability, cost, and real-world performance.

What Is Ringlock Scaffolding?

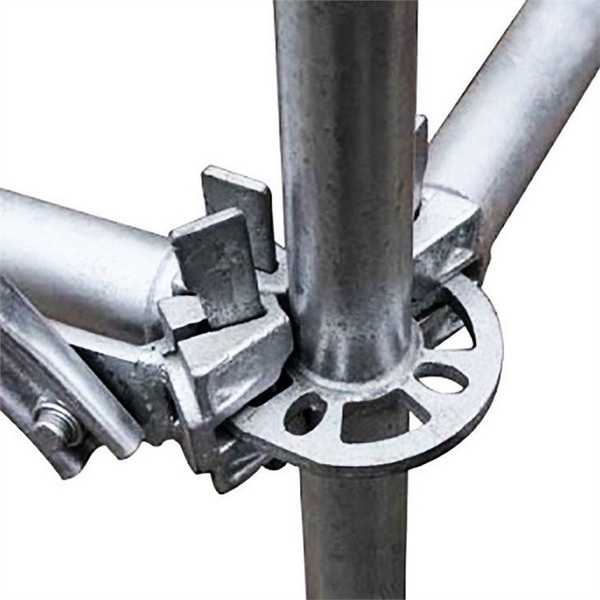

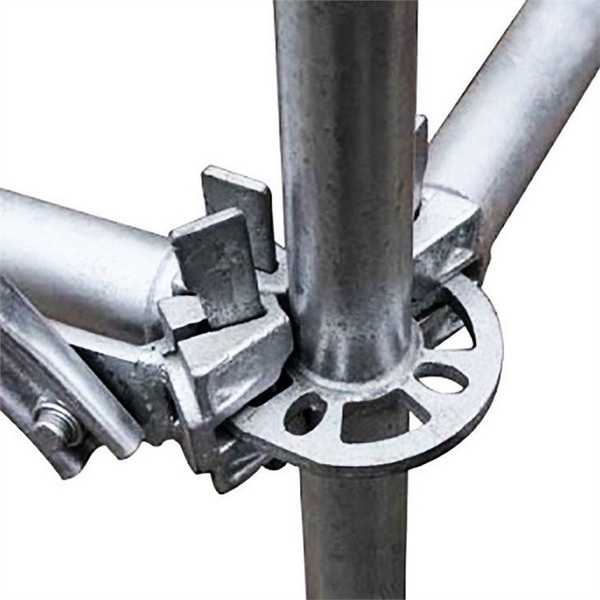

Ringlock scaffolding is a modular system featuring vertical standards with rosette (ring) connectors welded at fixed intervals. Horizontal ledgers and diagonal braces connect to these rosettes using wedge-heads, allowing up to eight connections at each node. This design enables rapid assembly, high flexibility, and secure, wobble-free structures.

Key Features of Ringlock Scaffolding

- Modular Design: Components can be combined in various configurations to suit different project requirements.

- Interlocking System: The wedge and rosette connection ensures a secure, wobble-free structure.

- High Load Capacity: Designed to carry heavy loads safely.

- Corrosion Resistance: Typically made from galvanized steel or aluminum alloys.

- Ease of Assembly: Minimal tools required; components drop and lock into place.

- Flexibility: Can be erected on uneven terrain, curved façades, or complex geometries.

What Is Cuplock Scaffolding?

Cuplock scaffolding uses vertical standards with regularly spaced cup connectors. Horizontals and braces are secured by inserting their ends into the bottom cup and locking them in place with the top cup, which is tightened by a simple hammer action. This system is renowned for its speed and simplicity.

Key Features of Cuplock Scaffolding

- Cup and blade locking mechanism (4-way connection at each node)

- Rapid assembly and dismantling

- High load capacity and stability

- Fewer loose components, reducing loss and maintenance

- Standardized, robust design for repetitive structures

Core Differences Between Ringlock and Cuplock Scaffolding

Feature | Ringlock Scaffolding | Cuplock Scaffolding |

Connection Type | Rosette (ring) with wedge | Cup and blade (top & bottom cups) |

Node Connections | Up to 8 directions | 4 directions |

Flexibility | Highly adaptable, complex shapes | Suited for straight, repetitive forms |

Assembly Speed | Fast, but requires alignment | Very fast, simple hammer action |

Load Capacity | Very high, excellent distribution | High, especially for vertical loads |

Safety Features | Integrated guardrails, anti-slip | Guardrails, toe boards, robust locks |

Applications | Complex, heavy-duty, irregular | Standard, repetitive, facade, shoring |

Cost | Slightly higher upfront | Generally more cost-effective |

Detailed Comparison: Features, Safety, and Performance

1. Locking Mechanism and Flexibility

- Ringlock scaffolding uses a rosette with up to eight connection points, allowing for multi-directional assembly and intricate configurations. This makes it ideal for irregular facades, curved structures, and projects requiring advanced geometry.

- Cuplock scaffolding offers a four-way cup connection, perfect for straight, repetitive structures. Its simplicity is a major advantage for large-scale, standardized projects.

2. Assembly and Disassembly Speed

- Cuplock scaffolding is often faster to assemble and dismantle due to its simple cup-and-blade locking system. Workers can connect up to four horizontals at a node in a single action, minimizing labor time.

- Ringlock scaffolding is also quick to assemble, though the need for precise alignment of wedges and rosettes may require slightly more time. However, its modularity reduces errors and increases overall efficiency.

3. Load-Bearing Capacity and Stability

- Both systems are engineered for high load-bearing capacity.

- Ringlock scaffolding distributes loads more evenly due to its multi-directional node, making it suitable for heavy-duty and industrial applications.

- Cuplock scaffolding is robust and excels in vertical load support, making it reliable for shoring and high-rise construction.

4. Safety Features

- Ringlock scaffolding integrates advanced safety features, including guardrails, toe boards, anti-slip platforms, and harness points. The rigid, interlocking design minimizes movement and assembly errors, enhancing worker safety.

- Cuplock scaffolding is also designed with safety in mind, featuring secure locking cups, guardrails, and toe boards. Its simple assembly reduces the risk of loose components and accidental dislodgement.

5. Durability and Maintenance

- Ringlock scaffolding is typically made from galvanized steel or aluminum, resisting corrosion and weathering. Its modular parts are reusable and easy to inspect.

- Cuplock scaffolding is also fully galvanized and low-maintenance. Its design minimizes the number of loose parts, reducing loss and simplifying upkeep.

Applications: Where Each System Excels

Ringlock Scaffolding

- Complex and irregular structures (curved façades, domes)

- High-rise buildings and skyscrapers

- Industrial plants, shipyards, and offshore rigs

- Projects requiring frequent reconfiguration or custom setups

- Event stages and grandstands

Cuplock Scaffolding

- Standard building façades

- Large-scale, repetitive structures (bridges, shoring)

- High-rise residential and commercial buildings

- Infrastructure repairs and maintenance

- Projects prioritizing speed and cost-efficiency

Cost Considerations and Long-Term Value

- Ringlock scaffolding typically has a higher upfront cost due to its advanced design and flexibility. However, its reusability, lower labor costs, and adaptability can yield significant long-term savings, especially for projects with complex requirements or frequent system changes.

- Cuplock scaffolding is generally more cost-effective for straightforward, repetitive projects. Its rapid assembly reduces labor costs, and the robust design ensures a long service life with minimal maintenance.

Table:

System | Upfront Cost | Labor Savings | Long-Term Value | Best For |

Ringlock | Higher | High | Excellent | Complex, heavy-duty, flexible |

Cuplock | Lower | High | Good | Standard, repetitive, façade |

Innovations and Trends in Modular Scaffolding

Ringlock Scaffolding

- Robotic Welding: Ensures uniform strength and precise manufacturing.

- Smart Scaffolding: Integration of sensors for load monitoring and safety alerts.

- Digital Planning: BIM integration for accurate project modeling and clash detection.

- Hybrid Systems: Combining ringlock with other types for seismic or ultra-tall structures.

Cuplock Scaffolding

- Enhanced Cup Design: Improved locking mechanisms for greater safety and ease.

- Lightweight Materials: Use of lighter, stronger alloys for easier handling.

- Prefabricated Accessories: Modular staircases, ladders, and safety gates for rapid deployment.

- Sustainability: Galvanized finishes and recyclable materials for eco-friendly construction.

How to Choose the Right System for Your Project

1. Project Complexity:

- For complex, irregular, or frequently changing structures, choose ringlock scaffolding.

- For straightforward, repetitive, or façade projects, cuplock scaffolding is ideal.

2. Load Requirements:

- Both systems offer high load capacity, but ringlock's superior distribution is better for heavy-duty needs.

3. Assembly Speed:

- Cuplock is typically faster for standard layouts; ringlock is efficient for complex or custom setups.

4. Budget:

- Cuplock offers lower upfront costs; ringlock delivers better long-term value for adaptable projects.

5. Safety Standards:

- Both systems meet or exceed international safety standards; ensure proper training and regular inspections.

6. Supplier Support:

- Choose reputable suppliers offering technical support, training, and after-sales service.

Conclusion

Both ringlock scaffolding and cuplock scaffolding have revolutionized the construction industry with their modular designs, safety features, and efficiency. Ringlock scaffolding stands out for its unmatched flexibility, superior load distribution, and adaptability to complex structures, making it the top choice for demanding or irregular projects. Cuplock scaffolding excels in speed, simplicity, and cost-effectiveness, ideal for standard, repetitive, and large-scale applications. The best system for your project depends on your specific requirements—complexity, budget, timeline, and safety priorities. By understanding the strengths and limitations of each, you can make an informed decision that maximizes safety, efficiency, and value on your construction site.

FAQ

1. What is the main difference between ringlock scaffolding and cuplock scaffolding?

Ringlock scaffolding uses a rosette connector allowing up to eight connections at each node, providing superior flexibility for complex structures. Cuplock scaffolding uses a cup-and-blade mechanism with four-way connections, making it faster for standard, repetitive assemblies.

2. Which system is safer: ringlock or cuplock scaffolding?

Both systems are engineered for safety, featuring integrated guardrails, toe boards, and anti-slip surfaces. Ringlock scaffolding offers more rigid, wobble-free connections, while cuplock scaffolding minimizes loose parts and assembly errors with its simple locking mechanism.

3. Is ringlock scaffolding more expensive than cuplock scaffolding?

Generally, ringlock scaffolding has a higher upfront cost due to its advanced design and flexibility. However, its reusability and efficiency can lead to long-term savings, especially for complex or frequently changing projects. Cuplock scaffolding is more cost-effective for standard applications.

4. Can both systems be used for high-rise or heavy-duty projects?

Yes, both ringlock scaffolding and cuplock scaffolding are suitable for high-rise and heavy-duty applications. Ringlock scaffolding is preferred for projects requiring complex geometry or heavy load distribution, while cuplock scaffolding is ideal for straightforward, repetitive high-rise work.

5. How do I choose between ringlock and cuplock scaffolding for my project?

Consider your project's complexity, load requirements, assembly speed, budget, and safety needs. Ringlock scaffolding is best for flexibility and complex layouts; cuplock scaffolding is best for speed and standardization.