Content Menu

● Introduction to Joint Clamp Scaffolding

● Key Components and How They Work

● Advantages of Joint Clamp Scaffolding in Residential Construction

>> 1. Versatility and Adaptability

>> 2. High Stability and Safety

>> 3. Strength and Load Capacity

>> 4. Cost-Effectiveness

>> 5. Ease of Assembly and Disassembly

● Limitations and Considerations

>> 1. Labor and Skill Requirements

>> 2. Inspection and Maintenance

>> 3. Potential for Lost Components

>> 4. Not Always the Fastest Option

● Step-by-Step Guide: Using Joint Clamp Scaffolding for Residential Projects

>> 1. Site Assessment and Planning

>> 2. Preparing the Foundation

>> 3. Assembling the Scaffold Structure

>> 4. Building Up and Out

>> 5. Bracing and Tying

>> 6. Final Inspection and Access

● Best Practices for Safety and Maintenance

● Real-World Examples and Case Studies

>> Residential Chimney Restoration

>> Custom Home Renovations

● Environmental Impact and Sustainability

● Cost Analysis: Joint Clamp vs. Other Scaffolding Systems

● Training and Regulatory Compliance

● Conclusion

● FAQ

>> 1. What is joint clamp scaffolding, and how does it differ from other types?

>> 2. Is joint clamp scaffolding safe for residential use?

>> 3. How often should joint clamp scaffolding be inspected?

>> 4. Can joint clamp scaffolding be reused for multiple projects?

>> 5. What are the main maintenance requirements for joint clamp scaffolding?

Joint clamp scaffolding, also known as tube and clamp or tube and coupler scaffolding, is a time-tested method for providing safe, stable, and flexible access to elevated work areas. Its adaptability and strength make it a popular choice in many sectors, but is it the right solution for residential construction? This in-depth guide explores the features, benefits, challenges, and best practices of joint clamp scaffolding in the context of residential building.

Introduction to Joint Clamp Scaffolding

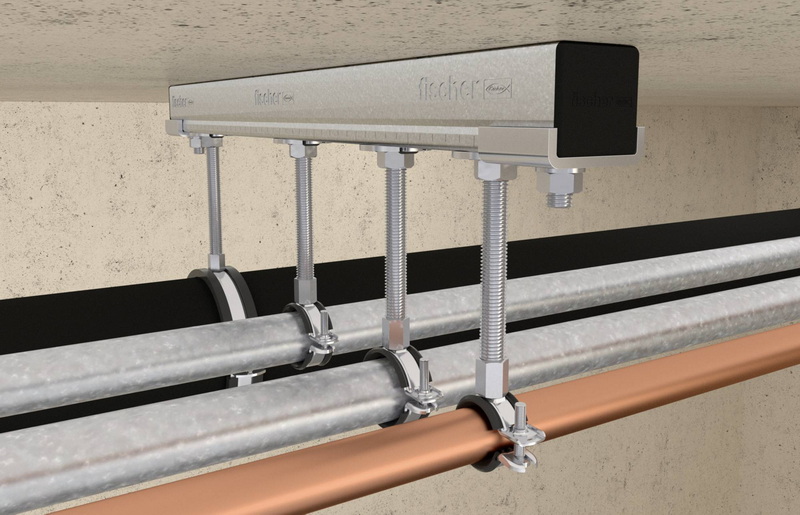

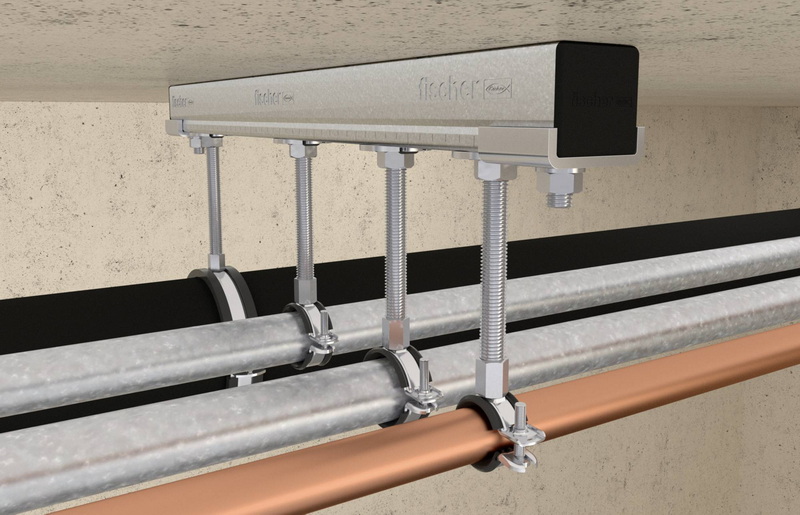

Joint clamp scaffolding is a modular system built from steel tubes and a variety of clamps or couplers. These clamps are engineered to join scaffold tubes at right angles, in straight lines, or at custom angles, allowing for a structure that can be tailored to virtually any shape or size. This flexibility is a key reason why joint clamp scaffolding is widely used in both commercial and residential construction.

Key Components and How They Work

The main elements of joint clamp scaffolding include:

- Steel Tubes: The primary structural members, available in various lengths and diameters.

- Joint Clamps (Couplers): These include right angle clamps, swivel clamps, and sleeve (joint pin) couplers. Each type serves a specific function in connecting tubes and ensuring stability.

- Base Plates and Sills: Distribute the load and provide a stable foundation.

- Platforms/Planks: Scaffold-grade boards that create working surfaces.

- Guardrails and Toe Boards: Safety features to prevent falls and dropped objects.

Advantages of Joint Clamp Scaffolding in Residential Construction

1. Versatility and Adaptability

Joint clamp scaffolding can be configured to fit irregular building shapes, tight spaces, and unique architectural features often found in residential projects. Swivel and right angle clamps allow for custom angles, making it possible to scaffold around chimneys, bay windows, and sloped roofs.

2. High Stability and Safety

Properly installed joint clamps provide a rigid, stable connection between scaffold tubes, minimizing movement and enhancing safety. This is crucial for residential sites where ground conditions may vary and where the safety of workers and occupants is paramount.

3. Strength and Load Capacity

Joint clamp scaffolding is engineered for strength. When assembled according to standards, a single-tube column can support significant loads—often up to 15kN–35kN—making it suitable for tasks ranging from bricklaying to roofing and facade work.

4. Cost-Effectiveness

Although the initial setup may require more labor than prefabricated systems, joint clamp scaffolding is reusable and durable. High-quality clamps resist corrosion and deformation, providing a long service life and reducing the need for frequent replacement.

5. Ease of Assembly and Disassembly

The simple, modular design of joint clamp scaffolding allows for quick assembly and dismantling, especially when using quality clamps and proper tools. This speeds up project timelines and reduces labor costs.

Limitations and Considerations

1. Labor and Skill Requirements

While joint clamp scaffolding is flexible, it requires skilled labor for correct assembly. Incorrect installation or poorly tightened clamps can compromise safety and stability.

2. Inspection and Maintenance

Frequent inspection is necessary to ensure all clamps are secure and components are free from damage or excessive wear. Missing or damaged parts must be replaced with manufacturer-approved components to maintain safety.

3. Potential for Lost Components

Clamps and fasteners are small and can be easily misplaced, especially on busy residential sites. Keeping an organized inventory and promptly collecting loose parts is essential.

4. Not Always the Fastest Option

For simple, repetitive residential projects (such as tract housing), frame scaffolding may be faster to erect. Joint clamp scaffolding is best suited for custom homes, renovations, or sites with access challenges.

Step-by-Step Guide: Using Joint Clamp Scaffolding for Residential Projects

1. Site Assessment and Planning

- Evaluate ground conditions, access points, and potential hazards.

- Design the scaffold layout to accommodate the building's shape and planned work.

- Calculate load requirements and select appropriate tube sizes and clamp types.

2. Preparing the Foundation

- Level the ground and use mudsills or timber sills on soft surfaces.

- Place base plates at each scaffold leg for even load distribution.

3. Assembling the Scaffold Structure

- Erect the first vertical post and attach the bottom bearer as close to the ground as possible.

- Use right angle clamps to connect horizontal runners and bearers.

- Square and level the structure using the 3-4-5 triangle method.

4. Building Up and Out

- Add additional bays and levels, ensuring all clamps are tightened to the recommended torque (typically 45 ft-lbs).

- Use swivel clamps for diagonal bracing and to accommodate architectural features.

- Install platforms, guardrails, and toe boards at each working level.

5. Bracing and Tying

- Install diagonal and horizontal bracing for stability.

- Tie the scaffold to the building at specified intervals (every 20–26 feet vertically, depending on width).

- Inspect all connections and adjust as needed.

6. Final Inspection and Access

- Ensure all components are secure and in good condition.

- Install ladders or stair towers for safe access.

- Conduct a final inspection by a competent person before use.

Best Practices for Safety and Maintenance

- Regular Inspections: Check clamps, tubes, and platforms for wear, damage, or corrosion at least weekly, and after severe weather or impacts.

- Proper Storage: Store clamps and tubes in a dry, organized area to prevent rust and loss.

- Lubrication: Ensure nuts and bolts move freely; lubricate as necessary to prevent seizing.

- Use Only Certified Parts: Replace damaged or missing components with manufacturer-approved parts.

- Worker Training: Ensure all personnel are trained in scaffold assembly, use, and safety protocols.

Real-World Examples and Case Studies

Residential Chimney Restoration

A historic home required chimney repairs on a steep roof. Joint clamp scaffolding was erected to provide safe, stable access for masons, allowing precise work and reducing project time. The adaptability of the system made it possible to scaffold around the chimney and sloped roofline, ensuring both worker safety and project efficiency.

Custom Home Renovations

For homes with unique architectural features—such as bay windows, wraparound porches, or multi-level roofs—joint clamp scaffolding enables custom configurations that other systems cannot match. Contractors report improved safety and faster project completion when using joint clamp scaffolding for these complex tasks.

Environmental Impact and Sustainability

Joint clamp scaffolding is inherently sustainable due to its reusability and long service life. High-quality steel tubes and clamps can be used for decades if properly maintained, reducing the need for frequent replacement and minimizing waste. Additionally, most components are recyclable at the end of their lifespan, supporting eco-friendly construction practices.

Cost Analysis: Joint Clamp vs. Other Scaffolding Systems

While the initial labor cost for erecting joint clamp scaffolding can be higher than for modular frame or system scaffolds, the long-term savings are significant due to durability and adaptability. For custom residential projects, the ability to reuse components and adapt the scaffold to unique structures often offsets the higher upfront labor costs. In contrast, modular systems may require purchasing or renting specialized parts for each project.

Cost Comparison

Factor | Joint Clamp Scaffolding | Frame Scaffolding | System Scaffolding |

Initial Labor | Higher | Lower | Moderate |

Material Longevity | Very High | Moderate | High |

Adaptability | Excellent | Limited | Good |

Reusability | Excellent | Good | Good |

Suitability (Custom) | Excellent | Poor | Good |

Training and Regulatory Compliance

Proper training is essential for anyone erecting, using, or dismantling joint clamp scaffolding. Workers should be familiar with local building codes, OSHA requirements, and manufacturer guidelines. Regular refresher courses and on-site supervision help maintain safety and compliance throughout the project.

Conclusion

Joint clamp scaffolding is not only suitable but often ideal for residential construction, especially on custom homes, renovations, or projects with complex access needs. Its versatility, strength, and safety features make it a reliable choice for builders and contractors. However, it requires skilled assembly, regular inspection, and diligent maintenance to ensure optimal performance and worker safety. When these best practices are followed, joint clamp scaffolding can deliver efficient, cost-effective, and safe access for a wide range of residential construction projects.

FAQ

1. What is joint clamp scaffolding, and how does it differ from other types?

Joint clamp scaffolding uses steel tubes connected by a variety of clamps (couplers) to create a flexible, modular structure. Unlike frame scaffolding, it can be adapted to fit irregular shapes and complex building features.

2. Is joint clamp scaffolding safe for residential use?

Yes, when properly installed and maintained, joint clamp scaffolding provides a stable and secure platform for residential construction tasks, including roofing, siding, and repairs.

3. How often should joint clamp scaffolding be inspected?

It should be inspected at least weekly, after severe weather, and after any incident that might affect its stability. A competent person should conduct these inspections.

4. Can joint clamp scaffolding be reused for multiple projects?

Yes, high-quality joint clamps and tubes are durable and reusable, provided they are properly maintained and stored between uses.

5. What are the main maintenance requirements for joint clamp scaffolding?

Regular inspection for wear, rust, and damage; prompt replacement of faulty components; lubrication of moving parts; and proper storage are essential for long-term performance.