Content Menu

● Introduction to Scaffolding Aluminum Planks Manufacturers and Suppliers in Europe

● Leading Scaffolding Aluminum Planks Manufacturers and Suppliers in Europe

>> 1. Wellmade Scaffold (China-based with European Market Presence)

>> 2. AAIT Scaffold (USA Manufacturer with European Export)

>> 3. Total Contec (European Standard Aluminum Plank Supplier)

>> 4. Rapid Scaffolding (European Supplier with OEM Capabilities)

>> 5. European Scaffolding Frame Suppliers (Various Manufacturers)

● Key Features of European Scaffolding Aluminum Planks

● Manufacturing Technologies and Quality Assurance

● Applications of European Scaffolding Aluminum Planks

● OEM Services and Customization

● Logistics and Export Solutions

● Innovations in European Scaffolding Aluminum Planks

● Conclusion

● FAQ

>> 1. What materials are used in European scaffolding aluminum planks?

>> 2. Are European scaffolding aluminum planks compliant with international safety standards?

>> 3. Do European manufacturers provide OEM services?

>> 4. What are the typical sizes and load capacities of European aluminum planks?

>> 5. How do European manufacturers ensure the quality and safety of their aluminum planks?

Europe boasts a robust and innovative construction materials industry, with numerous reputable scaffolding aluminum planks manufacturers and suppliers delivering high-quality, safe, and durable products. These companies serve a broad spectrum of clients including construction firms, industrial enterprises, wholesalers, and international brands seeking OEM partnerships. This article provides an extensive overview of the leading scaffolding aluminum planks manufacturers and suppliers in Europe, highlighting their product features, manufacturing technologies, OEM capabilities, and global reach.

Introduction to Scaffolding Aluminum Planks Manufacturers and Suppliers in Europe

Scaffolding aluminum planks are essential for creating safe and stable working platforms on construction and industrial sites. European manufacturers have developed advanced aluminum planks characterized by their lightweight construction, superior corrosion resistance, and compliance with stringent European safety standards such as EN 12811 and BS 2482.

Compared to traditional wooden or steel planks, aluminum scaffolding planks offer enhanced durability, reduced maintenance, and ease of handling. Their growing popularity in Europe stems from the demand for safer, longer-lasting, and more environmentally friendly scaffolding solutions.

The European market's focus on sustainability and worker safety has driven manufacturers to adopt cutting-edge technologies and eco-friendly materials. This ensures that scaffolding aluminum planks not only meet performance requirements but also align with environmental regulations and corporate social responsibility goals.

Leading Scaffolding Aluminum Planks Manufacturers and Suppliers in Europe

1. Wellmade Scaffold (China-based with European Market Presence)

- Product Range: Aluminum planks, steel boards, wood planks in various sizes

- Certifications: ISO 9001, CE certified, compliant with BS 2482, OSHA, AS1577, and EN BS 12811 standards

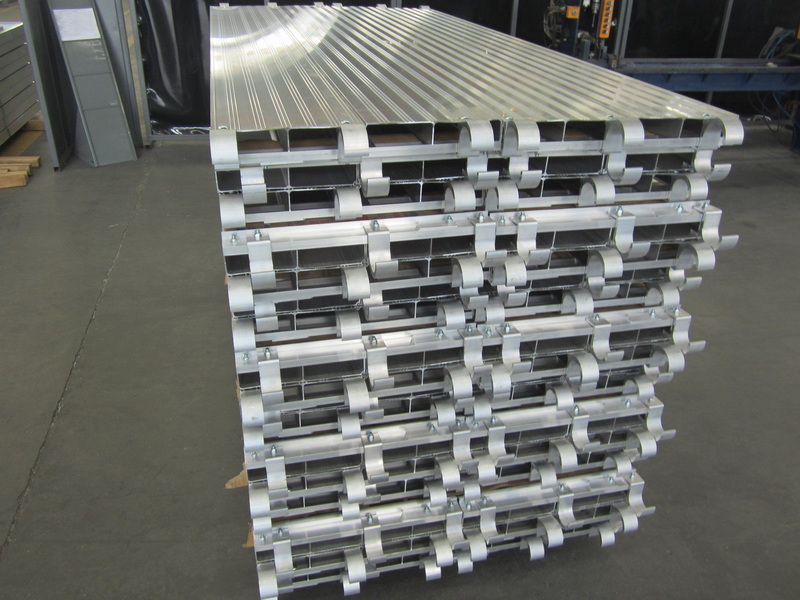

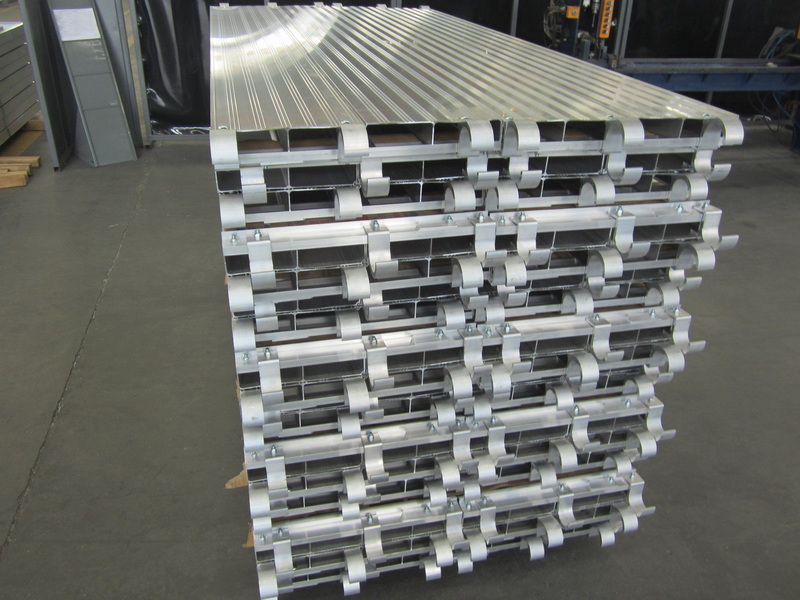

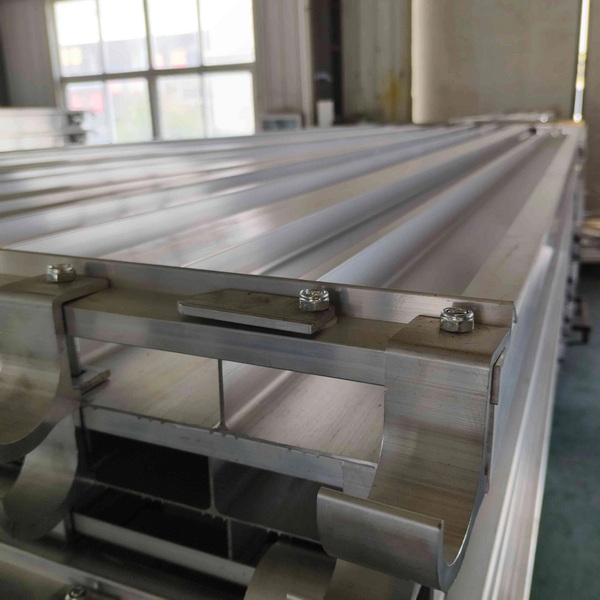

- Features: Lightweight aluminum planks with anti-slip grooved surfaces, riveted hooks for secure scaffold attachment, load tested for safety

- OEM Services: Custom sizes and designs, private labeling, and tailored packaging for European clients

- Applications: Compatible with steel ringlock scaffolds and frame scaffolds widely used across Europe

- Quality Control: Mock-up inspections, welding penetration tests, and ultimate bearing tests ensure reliability

2. AAIT Scaffold (USA Manufacturer with European Export)

- Product Range: Aluminum scaffold planks in 7 ft and 10 ft lengths, widths around 19 inches

- Load Capacity: 7 ft plank supports 75 lbs per square foot; 10 ft plank supports 50 lbs per square foot

- Features: Reinforced undersides for strength, grooved top surface for water drainage and traction, rust-resistant aluminum construction

- OEM Services: Custom lengths and branding available for European distributors and wholesalers

- Use Cases: Suitable for suspended and supported scaffolds, masonry, and stucco work

3. Total Contec (European Standard Aluminum Plank Supplier)

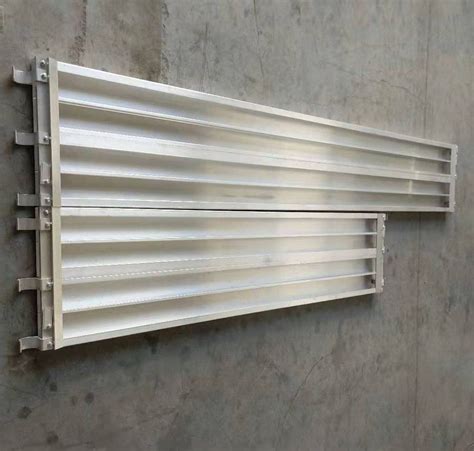

- Product Range: Aluminum planks manufactured per European standards, sizes customizable

- Certifications: EN 12811 compliant

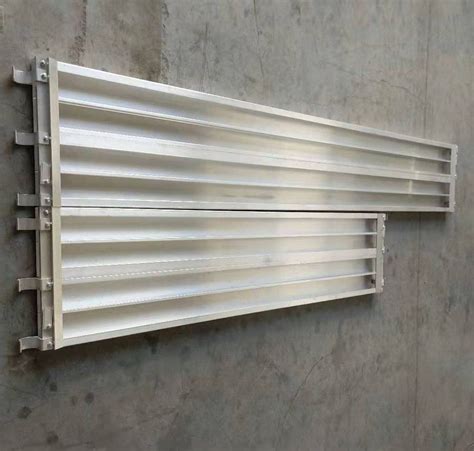

- Features: Durable, anti-slip surfaces, hooks for secure scaffold attachment, lightweight design

- OEM Services: Custom branding, packaging, and sizing tailored to client needs

- Market: Serves construction and industrial sectors across Europe

4. Rapid Scaffolding (European Supplier with OEM Capabilities)

- Product Range: Aluminum planks, scaffolding frames, and accessories

- Strengths: Emphasis on product durability and safety, adherence to European standards

- OEM Services: Full customization for international clients, including private label manufacturing

- Export: Supplies to multiple European countries and beyond

5. European Scaffolding Frame Suppliers (Various Manufacturers)

- Product Range: Aluminum planks compatible with ringlock and frame scaffolding systems

- Certifications: EN and ISO standards compliant

- OEM Services: Available for bulk orders, including custom dimensions and branding

- Applications: Construction, industrial maintenance, and infrastructure projects across Europe

Key Features of European Scaffolding Aluminum Planks

- Lightweight and Durable: Aluminum planks are significantly lighter than steel, reducing worker fatigue and simplifying handling without compromising strength.

- Corrosion Resistance: Aluminum's natural resistance to rust ensures long service life, especially in damp or coastal environments common in Europe.

- Safety Compliance: European manufacturers rigorously test planks to meet EN 12811, BS 2482, and other relevant safety standards.

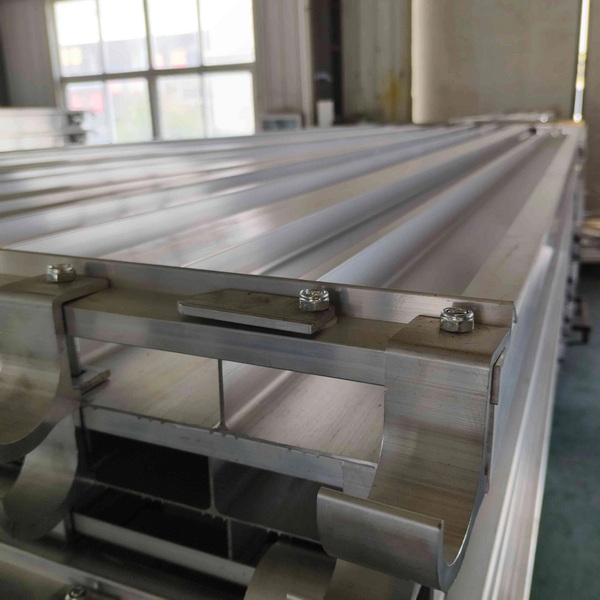

- Anti-Slip Surfaces: Grooved or ribbed tops prevent slips and falls, a critical safety feature on scaffolding platforms.

- Versatile Sizes: Standard widths around 19 inches and lengths from 7 to 10 feet, with custom sizes available to suit diverse scaffolding systems.

- Secure Attachment: Riveted hooks or clamps ensure planks remain stable on scaffolding frames, preventing movement or dislodgement.

Manufacturing Technologies and Quality Assurance

European manufacturers employ advanced technologies to produce high-quality scaffolding aluminum planks:

- Extrusion and Anodizing: Aluminum is extruded into precise plank profiles and anodized or powder-coated to enhance corrosion resistance and surface hardness.

- Automated Welding and Riveting: Ensures consistent strength and durability of plank hooks and reinforcements.

- Rigorous Testing: Load-bearing capacity, fatigue resistance, and slip-resistance tests are conducted per European standards.

- Quality Control: Continuous inspection during production, including welding penetration tests and load tests, guarantee product reliability.

- Sustainability: Many manufacturers prioritize eco-friendly processes, including recycling aluminum scrap and reducing emissions.

The integration of Industry 4.0 technologies such as real-time monitoring and automated quality checks further enhances product consistency and reduces defects, ensuring scaffolding aluminum planks meet the highest standards.

Applications of European Scaffolding Aluminum Planks

- Construction Sites: Widely used on residential, commercial, and industrial projects to provide safe working platforms.

- Industrial Maintenance: Facilitate access for equipment installation, repair, and inspection in factories and plants.

- Infrastructure Projects: Essential for bridge, tunnel, and road construction and maintenance.

- Event Staging: Temporary platforms for concerts, exhibitions, and sports events requiring rapid assembly.

- Rental Services: Many European suppliers offer rental options with installation and safety training for contractors.

The versatility of aluminum planks allows them to be adapted for specialized applications such as shipbuilding and offshore platforms, where corrosion resistance and lightweight construction are paramount.

OEM Services and Customization

European scaffolding aluminum plank manufacturers offer extensive OEM services, enabling foreign brands, wholesalers, and producers to:

- Customize Dimensions: Length, width, and thickness tailored to specific project or market needs.

- Private Labeling: Branding on planks and packaging to enhance market presence.

- Technical Support: Assistance with product selection, installation, and compliance documentation.

- Bulk Orders: Competitive pricing and flexible production runs for large volume clients.

- Packaging Solutions: Customized packaging to protect products during transport and facilitate handling.

OEM partnerships often include collaborative product development, allowing clients to influence design improvements and incorporate unique features that address specific market demands.

Logistics and Export Solutions

European manufacturers and suppliers provide comprehensive logistics support:

- Robust Packaging: Use of corrosion-resistant wraps, reinforced crates, and modular packing to ensure product integrity during shipping.

- Global Shipping: Coordination with international freight forwarders for timely delivery worldwide.

- Documentation: Full compliance with export regulations, including certificates of conformity and safety standards.

- After-Sales Support: Warranty services and responsive customer care for international clients.

Many suppliers also offer drop-shipping and vendor-managed inventory services, streamlining supply chains for global customers.

Innovations in European Scaffolding Aluminum Planks

- Smart Safety Features: Integration of anti-slip coatings and ergonomic designs to enhance worker safety.

- Modular and Adjustable Systems: Quick-lock hooks and adjustable lengths for flexible scaffold configurations.

- Eco-Friendly Manufacturing: Adoption of sustainable materials and processes to reduce environmental impact.

- Digital Solutions: RFID tagging and digital inventory management for efficient asset tracking.

European manufacturers are also exploring the use of composite materials and hybrid aluminum-plastic planks to further reduce weight while maintaining strength and durability.

Conclusion

Europe's scaffolding aluminum planks manufacturers and suppliers are recognized worldwide for their commitment to quality, safety, and innovation. Combining advanced manufacturing technologies with strict adherence to European and international standards, these companies produce lightweight, durable, and customizable aluminum planks suitable for a wide range of construction and industrial applications. Their comprehensive OEM services, robust logistics support, and dedication to sustainability make them ideal partners for foreign brands, wholesalers, and producers seeking reliable and high-performance scaffolding solutions.

FAQ

1. What materials are used in European scaffolding aluminum planks?

European scaffolding aluminum planks are made from high-grade aluminum alloys, often 6061 or similar, that offer excellent strength, corrosion resistance, and lightweight properties.

2. Are European scaffolding aluminum planks compliant with international safety standards?

Yes, they comply with European standards such as EN 12811 and BS 2482, as well as OSHA and ANSI standards for export markets.

3. Do European manufacturers provide OEM services?

Absolutely. Most leading European manufacturers offer OEM services including custom sizing, private labeling, packaging, and technical support.

4. What are the typical sizes and load capacities of European aluminum planks?

Standard widths are about 19 inches, with lengths ranging from 7 to 10 feet. Load capacities typically meet or exceed 75 lbs per square foot for heavy-duty applications.

5. How do European manufacturers ensure the quality and safety of their aluminum planks?

Through advanced manufacturing techniques, automated welding, anodizing, and rigorous testing including load, fatigue, and slip resistance.