Content Menu

● What is Ringlock Scaffolding?

● Key Features of Ringlock Scaffolding

● Why Choose Ringlock Scaffolding?

>> Efficiency and Speed

>> Safety and Stability

>> Versatility

>> Durability

● What to Look for When Buying Ringlock Scaffolding

>> 1. Material Quality and Steel Grade

>> 2. Rosette and Connection Mechanism

>> 3. Range of Components and Accessories

>> 4. Compliance with Standards

>> 5. Supplier Reputation and Support

● Technical Specifications of Ringlock Scaffolding Standards (Example)

● Installation and Maintenance Tips

>> Proper Assembly

>> Regular Inspection

>> Storage and Handling

● Applications of Ringlock Scaffolding

● Conclusion

● FAQ

>> 1. What are the core components of Ringlock scaffolding?

>> 2. How does the wedge locking system improve safety?

>> 3. What steel grades are used in quality Ringlock scaffolding?

>> 4. Why is galvanization important for Ringlock scaffolding?

>> 5. Can Ringlock scaffolding be customized for specific projects?

Ringlock scaffolding has become one of the most popular modular scaffolding systems worldwide due to its versatility, safety, and efficiency. Whether you are a contractor, supplier, or construction company looking to invest in Ringlock scaffolding, understanding what to consider before purchasing is crucial to ensure you get high-quality, durable, and compliant equipment suitable for your specific projects.

What is Ringlock Scaffolding?

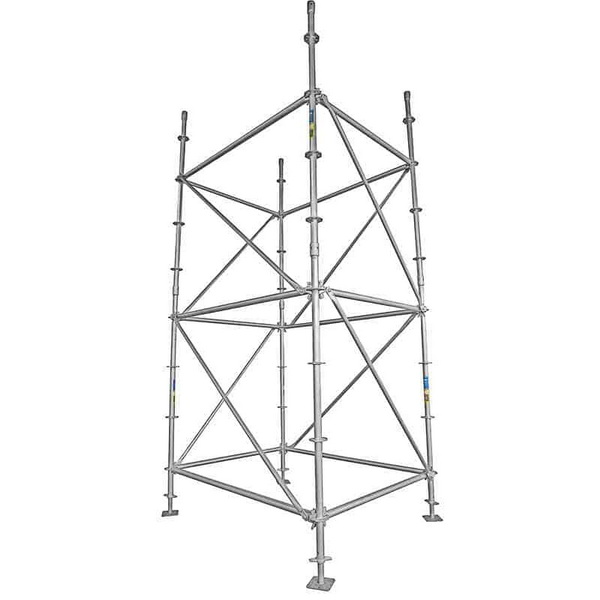

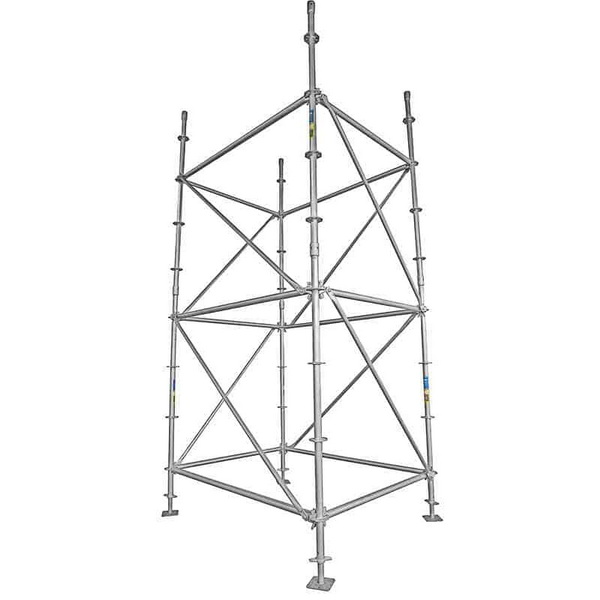

Ringlock scaffolding is a modular scaffolding system characterized by its unique rosette or ring connector welded onto vertical standards. This rosette allows for multiple ledgers and braces to be connected securely at various angles, offering exceptional flexibility and strength. The system uses wedge-head locking mechanisms to secure components quickly and safely without bolts or nuts.

Key Features of Ringlock Scaffolding

- Modular Design: Core components include vertical standards with welded rosettes, horizontal ledgers, diagonal braces, base jacks, and decking.

- Rosette Connector: Features 8 holes—4 smaller holes at 90° intervals and 4 larger holes in between—allowing versatile connection angles.

- Welded Rosettes: Positioned every 50 cm on vertical standards for consistent and secure connections.

- High Load Capacity: Supports heavy industrial and commercial loads with robust steel construction.

- Galvanized Finish: Hot-dip galvanizing or electro-galvanizing for corrosion resistance and durability.

- Flexible Dimensions: Different lengths and component types to suit various project requirements.

Why Choose Ringlock Scaffolding?

Efficiency and Speed

Ringlock scaffolding's wedge-head locking mechanism allows for fast and tool-light assembly and disassembly, significantly reducing labor time and costs compared to traditional tube and clamp systems.

Safety and Stability

The multi-angle rosette connections create a rigid lattice structure that offers superior stability and load distribution, reducing the risk of scaffold failure. The system also supports the attachment of personal protective equipment (PPE) and safety accessories.

Versatility

Ringlock scaffolding adapts to complex geometries, including curved facades and irregular structures, making it suitable for a wide range of applications from residential to heavy industrial construction.

Durability

Manufactured from high-strength Q235 or Q345 carbon steel with galvanized finishes, Ringlock scaffolding resists corrosion and wear, ensuring longevity and sustained safety on site.

What to Look for When Buying Ringlock Scaffolding

1. Material Quality and Steel Grade

High-quality Ringlock scaffolding is made from carbon steel grades S235 or S355 (equivalent to Q235/Q345). These grades ensure sufficient strength and flexibility under load.

- Check if the steel tubing has a standard outer diameter of 48.3 mm and a wall thickness typically around 3.25 mm.

- Confirm that the components are hot-dip galvanized (HDG) or electro-galvanized to prevent rust.

2. Rosette and Connection Mechanism

- The rosette should be welded directly onto the vertical standard at regular 500mm intervals.

- It should have 8 holes for versatile connections (4 small, 4 large).

- The wedge-head locking system must be casted and movable but not detachable, preventing loose components and ensuring a strong node connection.

3. Range of Components and Accessories

A quality Ringlock scaffolding system includes a wide range of components:

- Standards (vertical posts) in various lengths (0.5m, 0.66m, 1m, 1.5m, 2m, etc.)

- Ledgers (horizontal tubes) and diagonal braces

- Base jacks and adjustable props for leveling

- Decking platforms with anti-slip surfaces

- Guardrails, toe boards, and safety accessories

Check if the supplier offers a comprehensive range of accessories to meet all your project needs.

4. Compliance with Standards

Ensure the Ringlock scaffolding complies with international safety and quality standards such as:

- EN 74-1: European standard for tube and coupler scaffolding

- BS 1139: British standard for scaffolding components

- ISO 9001: Quality management certification

- OSHA regulations (if applicable to your region)

Compliance guarantees that the scaffolding system is tested and certified for safety and performance.

5. Supplier Reputation and Support

- Choose suppliers with proven experience in manufacturing or distributing Ringlock scaffolding.

- Look for suppliers who provide OEM services, customization options, and after-sales support.

- Verify customer reviews, certifications, and the ability to deliver components with consistent quality.

- Consider suppliers offering logistics support such as packaging, shipping, and documentation.

Technical Specifications of Ringlock Scaffolding Standards (Example)

Item Code | Description | Length (m) | Weight (kg) | Steel Grade | Finishing |

WRSP4805 | 0.5m Ringlock Standard | 0.5 | 3.15 | S235/S355 | Hot Dip Galvanized |

WRSP4807 | 0.66m Ringlock Standard | 0.66 | 3.72 | S235/S355 | Hot Dip Galvanized |

WRSP4810 | 1.0m Ringlock Standard | 1.0 | 5.45 | S235/S355 | Hot Dip Galvanized |

WRSP4815 | 1.5m Ringlock Standard | 1.5 | 7.75 | S235/S355 | Hot Dip Galvanized |

WRSP4820 | 2.0m Ringlock Standard | 2.0 | 10.05 | S235/S355 | Hot Dip Galvanized |

Installation and Maintenance Tips

Proper Assembly

- Always follow manufacturer instructions for correct wedge insertion and rosette engagement.

- Use trained personnel to ensure safety and structural integrity.

- Verify that all components are securely locked before use.

Regular Inspection

- Inspect scaffolding daily for loose wedges, damaged components, or corrosion.

- Replace any worn or damaged parts immediately.

- Check the base plates and jacks for stability and leveling.

Storage and Handling

- Store components in a dry, ventilated area to prevent rust.

- Handle parts carefully to avoid dents or damage to the rosettes and tubes.

Applications of Ringlock Scaffolding

Ringlock scaffolding is widely used in:

- Commercial and industrial construction

- Bridge and infrastructure projects

- Power plants and petrochemical facilities

- Shipbuilding and offshore platforms

- Event staging and temporary structures

Its adaptability and safety features make it suitable for projects demanding high load capacity and complex geometries.

Conclusion

When purchasing Ringlock scaffolding for sale, prioritizing quality, compliance, and supplier reliability is essential for safety and project success. Look for scaffolding made from high-grade steel with welded rosettes, equipped with a secure wedge-lock mechanism, and finished with corrosion-resistant galvanization. A comprehensive range of components and accessories, adherence to international safety standards, and strong supplier support are critical factors.

Ringlock scaffolding offers unmatched versatility, strength, and safety compared to traditional systems, making it a smart investment for modern construction projects. By carefully evaluating these factors before buying, you ensure that your scaffolding system will provide safe, efficient, and durable access solutions for years to come.

FAQ

1. What are the core components of Ringlock scaffolding?

The core components include vertical standards with welded rosettes, horizontal ledgers, diagonal braces, base jacks, and decking platforms.

2. How does the wedge locking system improve safety?

The wedge locking system securely locks ledgers and braces into the rosette, preventing accidental loosening and providing multi-angle connections for stability.

3. What steel grades are used in quality Ringlock scaffolding?

High-quality Ringlock scaffolding is typically made from S235 or S355 (Q235/Q345) carbon steel, ensuring strength and durability.

4. Why is galvanization important for Ringlock scaffolding?

Galvanization protects the steel components from corrosion, extending the lifespan and maintaining safety in harsh environments.

5. Can Ringlock scaffolding be customized for specific projects?

Yes, many suppliers offer OEM services and customization options for lengths, finishes, and accessories to meet project-specific requirements.