Content Menu

● Introduction to Scaffolding Tubes in Europe

● Leading Scaffolding Tube Manufacturers and Suppliers in Europe

● Product Range and Technical Features

>> Steel Scaffolding Tubes

>> Aluminum Scaffold Tubes

>> Couplers and Tube Clamps

>> Modular Scaffolding Systems

>> Accessories and Safety Components

>> Custom Manufacturing and OEM Services

● Manufacturing Excellence and Quality Assurance

● Industry Trends and Innovations

● Applications of Scaffolding Tubes Across Europe

● Conclusion

● FAQ

>> 1. What defines the European standards for scaffolding tubes?

>> 2. How do manufacturers guarantee the safety and durability of scaffold tubes?

>> 3. Are custom scaffold tubes available to meet unique construction needs?

>> 4. Why are modular scaffolding systems preferred in European construction?

>> 5. How is digital technology transforming scaffolding tube use?

The European construction sector depends heavily on reliable scaffolding systems, with scaffolding tubes serving as the backbone for worker safety and operational efficiency. This in-depth article profiles the top scaffolding tube manufacturers and suppliers across Europe, detailing their products, processes, market trends, and innovations. It is tailored for global brands, wholesalers, and manufacturers seeking authoritative information on sourcing and partnering within the European scaffolding market.

Introduction to Scaffolding Tubes in Europe

At the core of every scaffolding system lies the scaffolding tube, a critical element designed to withstand substantial loads while ensuring structural stability and worker safety. European scaffold tubes commonly conform to the EN 39 standard, stipulating requirements for cold-formed, welded carbon steel tubes used in scaffold construction. These tubes typically feature an outer diameter of 48.3mm with wall thicknesses of 3.2mm to 4.0mm, selected according to load demands and safety protocols.

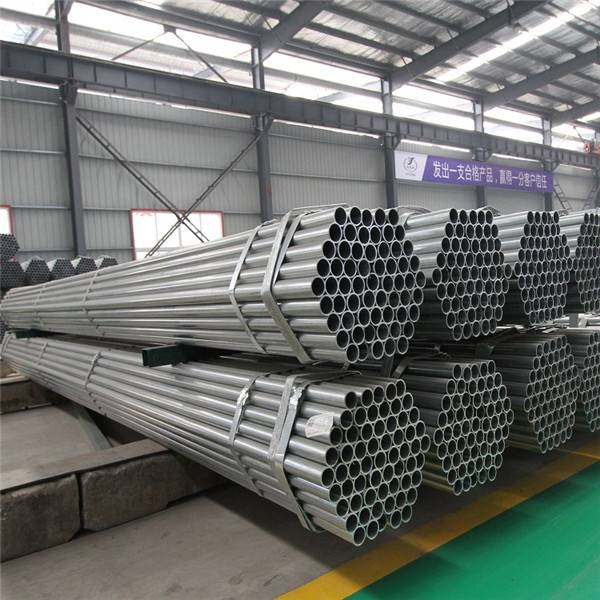

Galvanization of steel tubes is mandatory to combat corrosion caused by exposure to elements on job sites. In some applications, lightweight aluminum tubes are preferred for their ease of handling without sacrificing essential strength in lighter-duty scaffolding.

Complementing tubes, related scaffolding components such as clamps, couplers, adjustable base plates, and platforms are integral to complete systems.

Leading Scaffolding Tube Manufacturers and Suppliers in Europe

Europe hosts a strong network of scaffolding tube manufacturers and suppliers known for world-class quality, innovation, and regulatory compliance. Major players with footprints across the continent include:

Manufacturer / Supplier | Headquarters | Products & Services | Standards & Certifications |

Layher Group | Germany | Steel & aluminum tubes, modular scaffolding systems, couplers, accessories | EN 39, EN 12810, EN 12811, ISO 9001 |

PERI Group | Germany | Scaffolding tubes, formwork, shoring systems, BIM enabled | EN 39, EN 12810, EN 12811, ISO 9001 |

ULMA Construction | Spain | Industrial scaffold tubes, shoring frames, ergonomic designs | EN 39, EN 12810, ISO 9001 |

Altrad Group | France | Scaffolding and shoring systems, lightweight and ergonomic | EN standards, ISO 9001 |

GBM Italy | Italy | Custom scaffold tubes, modular systems, CE marking | CE, EN 39, ISO 9001 |

Duscaff | UAE/Europe | Scaffold tubes, cuplock systems, fittings with European approval | BS EN 12810-1, BS EN 12811-1 |

BSL Europe | Netherlands | Steel tubes, couplers, scaffolding accessories | ISO 9001, EN 39, CE compliance |

Wellmade Group (China OEM) | China/Europe | OEM supplier focused on EN compliant galvanized scaffold tubes and fittings | EN standards, ISO 9001 |

These manufacturers support the European market with state-of-the-art tubing solutions and comprehensive services, maintaining strict adherence to safety and performance standards.

Product Range and Technical Features

European manufacturers cover an extensive product range featuring the following categories:

Steel Scaffolding Tubes

Primarily made from cold-formed carbon steel, these tubes are hot-dip galvanized for corrosion resistance and durability in harsh environments. Their standard outer diameter is 48.3mm with wall thicknesses tailored for varying load classes, ensuring compliance with EN 39 for structural performance.

Aluminum Scaffold Tubes

Aluminum tubes offer a lightweight alternative favored in applications requiring portability and ease of assembly, such as light commercial and residential scaffolding. Although lighter, aluminum tubes maintain compliance with safety standards for specified load limits.

Couplers and Tube Clamps

Various types of clamps ensure secure scaffold tube connections, including:

- Right-Angle Couplers — for perpendicular tube joins providing rigidity.

- Swivel Couplers — allow angular adjustments for complex scaffolding geometries.

- Sleeve and Putlog Couplers — facilitate longitudinal and crosswise tube connections.

- Forged Couplers — specialized for enhanced strength and safety-critical joints.

Modular Scaffolding Systems

The popularity of systems like ringlock, cuplock, and kwikstage continues to rise in Europe. These combine standard scaffolding tubes with engineered locking mechanisms, speeding assembly while enhancing safety and load distribution.

Accessories and Safety Components

These include base plates, adjustable screw jacks, guardrails, scaffold boards, outriggers, and casters, forming a complete scaffolding infrastructure compliant with European safety regulations.

Custom Manufacturing and OEM Services

Many top suppliers provide customized tubes for length, coating, and packaging to satisfy unique project specifications or private-label requirements. OEM partnerships, such as those with the Wellmade Group in China, ensure competitive and quality-assured scaffold tubes for the European market.

Manufacturing Excellence and Quality Assurance

The manufacturing process employed by leading European scaffolding tube manufacturers and suppliers is designed for precision and compliance:

1. Material Selection: Steel sourced with certified chemical and mechanical properties.

2. Roll Forming and Welding: Tubes shaped with precision rollers, longitudinally welded with high-frequency technology, and subjected to weld integrity testing.

3. Galvanization: Hot-dip galvanizing applies a robust zinc coating, meeting European corrosion resistance criteria.

4. Cutting and Finishing: Tubes cut to standard or custom lengths, ends prepared for fittings.

5. Non-Destructive Testing: Advanced ultrasonic and eddy current techniques check seam and material consistency.

6. Inspection and Certification: Comprehensive checks ensure EN and ISO standards are met; production marked and documented.

7. Logistics: Efficient warehousing and distribution networks enable timely delivery across Europe.

This meticulous quality assurance guarantees that scaffolding tubes meet high safety, durability, and performance demands.

Industry Trends and Innovations

European scaffolding tube manufacturers embrace trends that enhance product value, safety, and environmental responsibility:

- Digitalization: Integration of BIM (Building Information Modeling) and real-time inventory tracking raise project accuracy and material management.

- Sustainability: Adoption of eco-friendly galvanizing, steel recycling, and energy-efficient manufacturing aligns with European environmental regulations.

- Advanced Alloys and Coatings: Development of aluminum alloys and powder coatings enhances tube durability with reduced weight.

- Enhanced Safety Features: Ergonomic tube handling systems and safety locks on couplers reduce accident risk during erection.

- Modular Flexibility: Growing adoption of modular scaffold systems allows rapid site adaptation and efficient worksite logistics.

- OEM Collaboration: European sourcing increasingly partners with global OEMs to optimize cost-efficiency while adhering to quality benchmarks.

Applications of Scaffolding Tubes Across Europe

Scaffolding tubes produced and supplied in Europe support applications including:

- Residential and commercial building scaffolding.

- Bridge, tunnel, and infrastructure construction.

- Industrial maintenance platforms in factories and plants.

- Temporary stages and event structures.

- Environmental remediation scaffolds.

- Specialty scaffolding for irregular architectural designs.

These varied uses demand high-quality scaffold tubes with verified load capacity and safety compliance.

Conclusion

Europe's scaffolding tube market exemplifies advanced manufacturing, unparalleled safety standards, and growing innovation. Leading scaffolding tube manufacturers and suppliers such as Layher Group, PERI, ULMA Construction, and GBM Italy deliver EN-certified products that provide robust, reliable, and adaptable scaffolding solutions.

The synergy between European brands and trusted OEM suppliers adds cost-effective flexibility to the supply chain without compromising quality. Whether through traditional galvanized steel tubes or lightweight aluminum options, the focus remains on worker safety, environmental responsibility, and efficient project delivery.

For global brands, wholesalers, and construction professionals seeking top-tier scaffolding tube manufacturing and supply in Europe, these companies represent unmatched expertise and comprehensive offerings essential for success across the continent's diverse construction landscape.

FAQ

1. What defines the European standards for scaffolding tubes?

Primarily, EN 39 governs scaffold tube dimensions, mechanical properties, and quality. Additional standards such as EN 12810 and EN 12811 apply to system scaffolding elements and performance criteria, ensuring scaffold safety and interoperability.

2. How do manufacturers guarantee the safety and durability of scaffold tubes?

Through stringent raw material certification, precise welding technologies, thick and uniform galvanizing, plus comprehensive non-destructive testing and final inspections aligned with EN and ISO requirements.

3. Are custom scaffold tubes available to meet unique construction needs?

Yes, customization regarding tube length, wall thickness, coating type, and packaging is widely available, enabling scaffolding suppliers to meet diverse project specifications and client branding requests.

4. Why are modular scaffolding systems preferred in European construction?

Their fast assembly, flexibility in configuration, improved load distribution, and integrated safety features make modular systems efficient and compliant with strict regulatory frameworks.

5. How is digital technology transforming scaffolding tube use?

Digital tools, especially BIM and inventory tracking via QR codes or RFID, optimize scaffold design accuracy, logistics, and safety management, minimizing delays and rework on construction sites.