Content Menu

● Understanding Scaffold Rack Systems

● Key Components of a Scaffold Rack System

● Benefits of Using a Scaffold Rack System

● Case Studies

>> Case Study 1: High-Rise Construction Project

>> Case Study 2: Industrial Facility Renovation

● Integrating Scaffold Rack Systems into Existing Projects

● Challenges and Considerations

● Conclusion

● FAQ

>> 1. What is a scaffold rack system?

>> 2. How does a scaffold rack improve safety?

>> 3. Can a scaffold rack system be customized?

>> 4. What are the cost implications of implementing a scaffold rack system?

>> 5. How do I integrate a scaffold rack system into an existing project?

● Citations:

In the construction industry, efficiency, safety, and organization are paramount. As projects become increasingly complex and demanding, construction companies are continually seeking innovative solutions to streamline their operations. One such solution is the scaffold rack system, which offers numerous benefits that enhance the overall construction process. This article explores the various advantages of using a scaffold rack system, supported by relevant visuals and videos to illustrate its effectiveness.

Understanding Scaffold Rack Systems

A scaffold rack system is a specialized storage solution designed to organize and store scaffolding materials efficiently. These systems are crucial for managing the various components of scaffolding, such as frames, planks, and accessories, ensuring that they are easily accessible when needed. By implementing a scaffold rack system, construction companies can improve workflow, reduce clutter on job sites, and enhance safety.

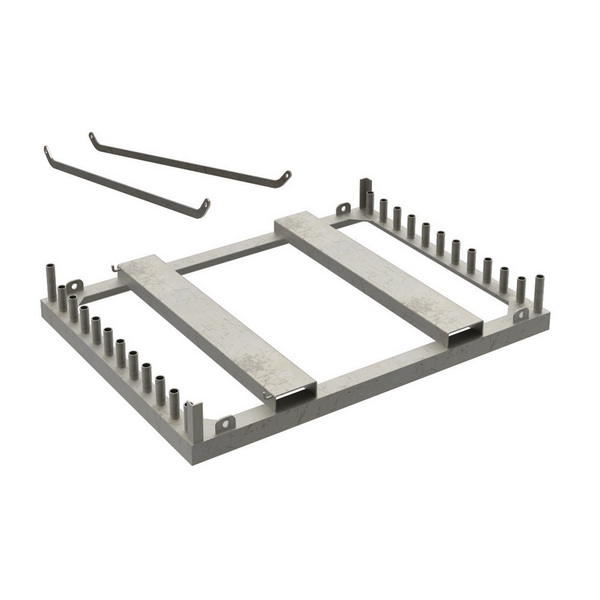

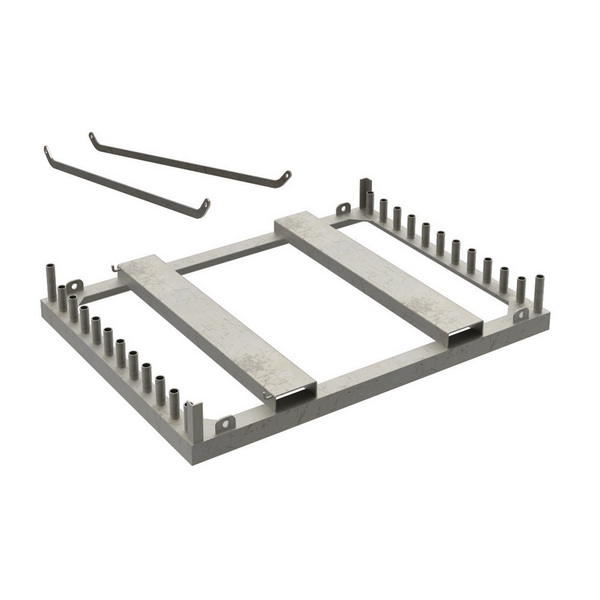

Key Components of a Scaffold Rack System

1. Vertical Supports: These provide the main structure for the rack, allowing it to bear heavy loads.

2. Horizontal Beams: These connect vertical supports and provide surfaces for storing scaffolding components.

3. Safety Features: Many scaffold rack systems include safety features such as guardrails or locking mechanisms to prevent accidents.

4. Adjustable Shelves: Some systems offer adjustable shelving to accommodate different sizes and types of scaffolding materials.

Benefits of Using a Scaffold Rack System

1. Enhanced Organization

A well-designed scaffold rack system allows for organized storage of scaffolding components, making it easier for workers to find what they need quickly. This reduces downtime spent searching for materials and contributes to a more efficient workflow.

Scaffold Rack Organization

2. Improved Safety

By keeping scaffolding materials organized and off the ground, scaffold rack systems help minimize tripping hazards on job sites. Additionally, proper storage reduces the risk of materials being damaged or misplaced.

- Reduced Risk of Accidents: An organized workspace decreases the likelihood of accidents caused by clutter or disorganization.

- Secure Storage: Many scaffold racks come with safety features that ensure materials are securely stored and less likely to fall.

3. Space Optimization

Scaffold rack systems maximize vertical space in storage areas or job sites, allowing construction companies to utilize their space more effectively. By storing materials vertically, companies can free up valuable floor space for other uses.

Space Optimization

4. Increased Efficiency

With all scaffolding components stored in one place, workers can quickly access what they need without wasting time searching through piles of materials. This efficiency translates into faster project completion times.

5. Cost Savings

Implementing a scaffold rack system can lead to significant cost savings over time:

- Reduced Labor Costs: With improved organization and accessibility, workers can complete tasks more quickly, reducing labor costs.

- Minimized Material Loss: Properly stored materials are less likely to be damaged or lost, saving money on replacements.

6. Versatility

Scaffold rack systems can be customized to fit various types of scaffolding materials and configurations. This versatility makes them suitable for different projects and construction environments.

7. Simplified Inventory Management

A scaffold rack system facilitates better inventory management by providing a clear view of available materials. This helps project managers keep track of what is on hand and what needs to be ordered.

8. Enhanced Mobility

Many scaffold rack systems are designed with mobility in mind, allowing them to be easily moved around job sites as needed. This flexibility enables construction companies to adapt quickly to changing project requirements.

Case Studies

Case Study 1: High-Rise Construction Project

In a recent high-rise construction project in Chicago, a scaffold rack system was implemented to organize scaffolding materials efficiently:

- Time Savings: The project team reported a 25% reduction in time spent retrieving scaffolding components.

- Increased Safety: The organized storage reduced clutter on the job site, leading to fewer accidents.

Case Study 2: Industrial Facility Renovation

An industrial facility undergoing renovation utilized a scaffold rack system to manage scaffolding materials during upgrades:

- Enhanced Workflow: Workers were able to access materials quickly, resulting in a 30% increase in productivity.

- Cost Savings: The organized storage minimized material loss and damage, leading to significant cost savings over the project's duration.

Integrating Scaffold Rack Systems into Existing Projects

Implementing a scaffold rack system into an existing project requires careful planning:

1. Assessment of Space Requirements: Evaluate the available space on-site to determine the best location for the scaffold rack system.

2. Design Considerations: Work with suppliers or manufacturers to design a system that meets project-specific needs while adhering to safety regulations.

3. Training Workers: Provide training on how to use the scaffold rack system effectively and safely.

Challenges and Considerations

While scaffold rack systems offer numerous benefits, there are challenges that must be addressed:

1. Initial Investment: The upfront costs associated with purchasing or installing a scaffold rack system can be significant.

2. Maintenance Requirements: Regular maintenance is essential to ensure that racks remain safe and functional over time.

3. Space Constraints: In some cases, existing structures may limit where racks can be installed.

Conclusion

In conclusion, a scaffold rack system is an invaluable asset for construction companies looking to improve organization, safety, efficiency, and cost-effectiveness on their job sites. By implementing these systems, companies can streamline their operations and create safer working environments for their employees. As construction projects continue to grow in complexity and scale, adopting advanced storage solutions like scaffold racks will be critical for maintaining competitiveness in the industry.

FAQ

1. What is a scaffold rack system?

A scaffold rack system is a specialized storage solution designed for organizing and storing scaffolding materials efficiently on construction sites.

2. How does a scaffold rack improve safety?

By keeping scaffolding materials organized and off the ground, scaffold racks minimize tripping hazards and reduce the risk of accidents caused by cluttered workspaces.

3. Can a scaffold rack system be customized?

Yes, many scaffold rack systems can be customized to accommodate various types of scaffolding materials and configurations based on project needs.

4. What are the cost implications of implementing a scaffold rack system?

While there may be initial costs associated with purchasing or installing a scaffold rack system, these costs are often offset by long-term savings in labor and material management.

5. How do I integrate a scaffold rack system into an existing project?

Integration involves assessing available space on-site, designing an appropriate storage solution with suppliers or manufacturers, and providing training for workers on its effective use.

Citations:

[1] https://www.unitedscaffold.ca/scaffold-news/3-reasons-to-use-scaffolding-for-construction/

[2] https://www.youtube.com/watch?v=veF4uSUtrEY

[3] https://peakscaffolding.ca/the-benefits-of-ringlock-scaffolding/

[4] https://www.youtube.com/watch?v=ByJaXeuIEfc

[5] https://aaitscaffold.com/scaffold-system/what-is-the-importance-of-scaffolding-in-construction/

[6] https://www.youtube.com/watch?v=RUsMOLkkGG0

[7] https://unimaxformwork.com/top-10-benefits-of-using-modern-scaffolding-systems-in-construction/

[8] https://www.shutterstock.com/video/search/system-scaffolding