Content Menu

● Introduction to Ringlock Scaffolding

● Key Components of Ringlock Scaffolding

● Factors Affecting Ringlock Scaffolding Price

>> 1. Project Location

>> 2. Project Duration

>> 3. Project Height and Complexity

>> 4. Scaffolding Materials

>> 5. Safety Regulations and Compliance

>> 6. Labor and Installation Costs

>> 7. Type of Scaffolding

>> 8. Additional Safety and Customization Needs

>> 9. Seasonal Demand

● Cost-Effectiveness of Ringlock Scaffolding

● Comparison with Traditional Scaffolding

● Conclusion

● FAQ

>> 1. What are the primary factors affecting Ringlock scaffolding price?

>> 2. How does the choice of material affect Ringlock scaffolding costs?

>> 3. What are the benefits of using Ringlock scaffolding despite its higher upfront cost?

>> 4. How does project duration impact Ringlock scaffolding costs?

>> 5. Can Ringlock scaffolding be customized for complex projects?

● Citations:

Ringlock scaffolding is a popular choice in the construction industry due to its versatility, ease of assembly, and high stability. However, the price of Ringlock scaffolding can vary significantly based on several factors. Understanding these factors is crucial for project managers and contractors to accurately budget and optimize costs. This article will delve into the key factors that affect the price of Ringlock scaffolding, providing insights into how these elements impact overall costs.

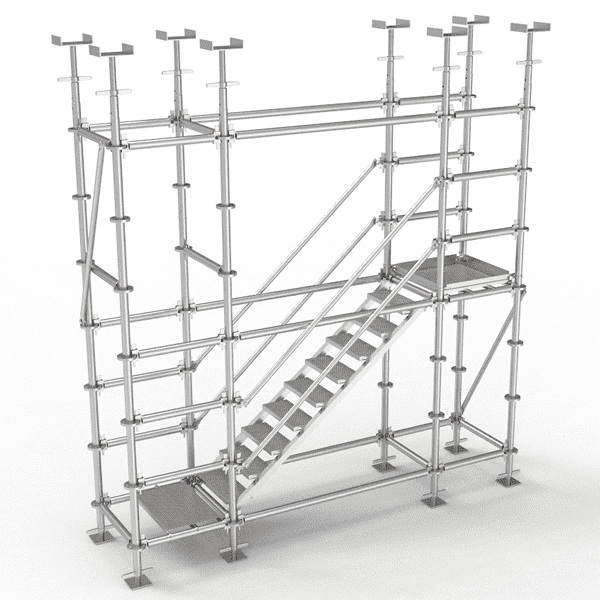

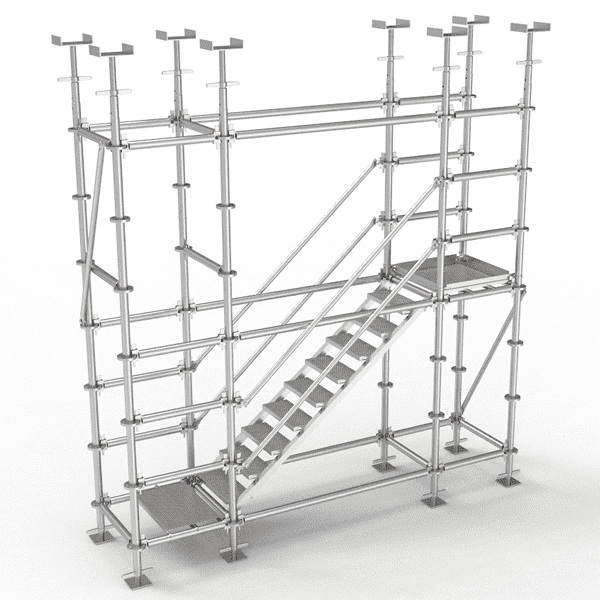

Introduction to Ringlock Scaffolding

Ringlock scaffolding is known for its modular design, which allows for quick assembly and disassembly. It consists of standards, ledgers, diagonal braces, and base plates, all designed to provide a stable working platform. The system is favored for its ability to support heavy loads and adapt to different site conditions.

Key Components of Ringlock Scaffolding

- Standards: These are the vertical posts that form the main structure of the scaffold.

- Ledgers: Horizontal beams that connect the standards and provide support for the working platform.

- Diagonal Braces: These ensure the stability of the scaffold by providing additional structural support.

- Base Plates: These are used to distribute the weight of the scaffold evenly on the ground.

Factors Affecting Ringlock Scaffolding Price

Several factors contribute to the overall cost of Ringlock scaffolding. Understanding these factors can help in making informed decisions about scaffolding purchases or rentals.

1. Project Location

The location of a project significantly affects scaffolding costs due to variations in labor rates, transportation costs, and material availability. For instance, projects in urban areas may have higher labor costs compared to rural areas[1].

2. Project Duration

The longer the project duration, the higher the scaffolding costs. This is because longer projects often require scaffolding to remain in place for extended periods, leading to higher rental fees or increased material costs if purchased[1][5].

3. Project Height and Complexity

The height and complexity of a project also impact scaffolding costs. Taller structures require more scaffolding, and complex projects may need customized scaffolding systems, which can be more expensive[1][2].

4. Scaffolding Materials

The choice of material affects costs due to differences in durability, weight-bearing capacity, and price. For example, steel is generally less expensive than aluminum but heavier and more durable[5].

5. Safety Regulations and Compliance

Compliance with safety regulations may require additional safety features or certifications, which can increase costs. Regular inspections and training are also necessary to ensure safety standards are met[1][5].

6. Labor and Installation Costs

Labor costs are a significant factor in scaffolding expenses. The ease of assembly and disassembly of Ringlock scaffolding can reduce labor costs compared to more complex systems[4][6].

7. Type of Scaffolding

The type of scaffolding, whether it's supported, suspended, or rolling, affects pricing. Ringlock scaffolding is generally more expensive upfront but offers long-term cost savings through reusability[2][4].

8. Additional Safety and Customization Needs

Projects requiring additional safety features or customized scaffolding solutions can increase costs. However, these features are essential for ensuring worker safety and project success[1].

9. Seasonal Demand

Seasonal fluctuations in demand can impact scaffolding prices. Peak construction seasons may see higher rental rates due to increased demand[1].

Cost-Effectiveness of Ringlock Scaffolding

Despite having a higher upfront cost compared to some alternatives, Ringlock scaffolding offers significant long-term savings. Its modular design allows for easy assembly and disassembly, reducing labor costs. Additionally, the components are reusable, making it a cost-effective option for frequent projects[4].

Comparison with Traditional Scaffolding

Ringlock scaffolding differs from traditional tube and clamp scaffolding in terms of structural design, construction methods, and cost. The use of higher strength materials in Ringlock scaffolding contributes to its higher price but also provides better stability and faster assembly times[6].

Conclusion

The price of Ringlock scaffolding is influenced by a variety of factors, including project location, duration, height, material choice, safety regulations, and labor costs. While it may have a higher upfront cost, Ringlock scaffolding offers long-term savings through its reusability and ease of assembly. By understanding these factors, project managers can better plan and optimize their scaffolding expenses.

FAQ

1. What are the primary factors affecting Ringlock scaffolding price?

The primary factors include project location, duration, height and complexity, scaffolding materials, safety regulations, labor costs, and the type of scaffolding used.

2. How does the choice of material affect Ringlock scaffolding costs?

The choice of material affects costs due to differences in durability, weight-bearing capacity, and price. For example, steel is generally less expensive than aluminum but heavier and more durable.

3. What are the benefits of using Ringlock scaffolding despite its higher upfront cost?

Ringlock scaffolding offers benefits such as reusability, reduced labor costs due to easy assembly and disassembly, and long-term cost savings. It also provides a stable and secure working platform.

4. How does project duration impact Ringlock scaffolding costs?

Longer projects require scaffolding to remain in place for extended periods, potentially leading to higher rental fees or increased material costs if purchased.

5. Can Ringlock scaffolding be customized for complex projects?

Yes, Ringlock scaffolding can be customized for complex projects. However, this may increase costs due to the need for specialized components and design.

Citations:

[1] https://www.ajbuildscaffold.com/factors-affecting-scaffolding-cost-per-square-foot

[2] https://rapid-scafform.com/how-to-calculate-the-rate-of-scaffolding/

[3] https://www.made-in-china.com/products-search/hot-china-products/Ringlock_Scaffolding_System_Price.html

[4] https://dss.net/top-5-benefits-of-ring-lock-scaffolding-systems/

[5] https://www.tp-scaffold.com/what-are-the-cost-factors-of-an-extensive-scaffolding-system.html

[6] https://www.adtoscaffold.com/new/comparison_of_ringlock_and_traditional_scaffolding.html

[7] https://apacsafety.com/ringlock-scaffolding-systems/

[8] https://apacsafety.com/how-to-reduce-costs-when-using-ringlock-scaffolding-system/

[9] https://www.adtoscaffold.com/new/cost_calculation_of_new_type_ringlock_scaffolding.html