Content Menu

● What Is Ringlock Scaffolding?

● Core Components of Ringlock Scaffolding

● Why Do Contractors Prefer Ringlock Scaffolding?

>> 1. Superior Flexibility and Versatility

>> 2. Speed and Efficiency in Assembly

>> 3. Unmatched Stability and Load Capacity

>> 4. Enhanced Safety Features

>> 5. Long-Term Durability and Cost-Effectiveness

● Technical Specifications and Standards

● Applications of Ringlock Scaffolding

● Installation and Maintenance Best Practices

● Comparison with Other Scaffolding Systems

● Additional Advantages of Ringlock Scaffolding

>> Ease of Transport and Storage

>> Environmental Benefits

>> Compatibility with Other Systems

● Conclusion

● FAQ

>> 1. What makes Ringlock scaffolding safer than traditional scaffolding systems?

>> 2. How quickly can Ringlock scaffolding be assembled?

>> 3. Is Ringlock scaffolding suitable for complex building shapes?

>> 4. What materials are used in Ringlock scaffolding components?

>> 5. Can Ringlock scaffolding be customized for specific project needs?

Ringlock scaffolding has become one of the most widely adopted modular scaffolding systems in the construction industry due to its versatility, safety, and efficiency. Contractors around the world prefer Ringlock scaffolding for its innovative design, ease of assembly, and adaptability to complex construction projects. This article provides an in-depth look at what Ringlock scaffolding is, its core features, advantages, and why it is favored by contractors.

What Is Ringlock Scaffolding?

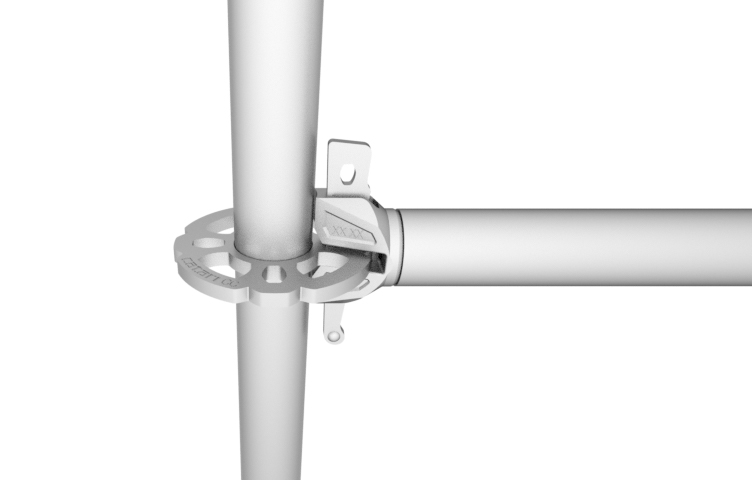

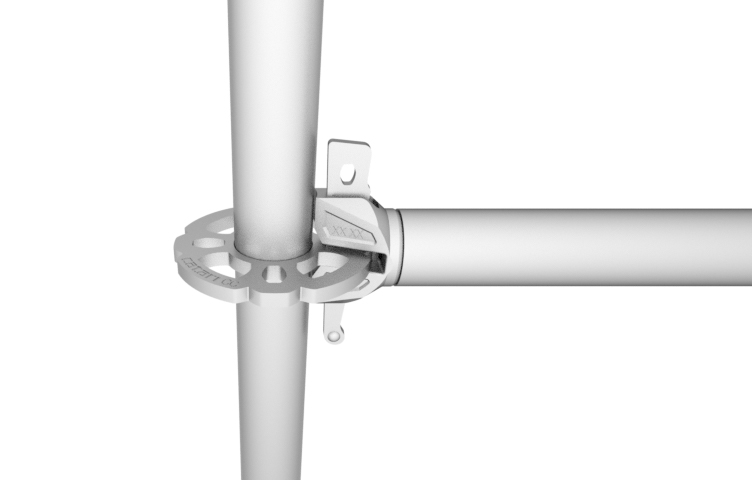

Ringlock scaffolding is a modular scaffolding system that uses a unique rosette or ring connector welded onto vertical standards (upright tubes). This rosette has multiple holes allowing horizontal ledgers and diagonal braces to be connected securely at various angles using wedge-head locking pins. This design enables rapid assembly and disassembly without the need for bolts or nuts, providing a highly flexible and robust scaffold structure.

Core Components of Ringlock Scaffolding

- Vertical Standards: Steel tubes with welded rosettes spaced every 500mm.

- Rosette Connectors: Circular discs with 8 holes (4 small and 4 large) for multi-directional connections.

- Horizontal Ledgers: Connect to the rosettes via wedge locks.

- Diagonal Braces: Provide lateral stability, also connected through the rosette.

- Base Jacks: Adjustable supports for leveling the scaffold.

- Decking Platforms: Anti-slip metal or wooden planks for safe working surfaces.

Why Do Contractors Prefer Ringlock Scaffolding?

1. Superior Flexibility and Versatility

Ringlock scaffolding's rosette design enables connections at up to 8 different angles on the same node, allowing contractors to build scaffolds that conform to complex geometries such as curved facades, circular tanks, tunnels, and irregular building shapes. This flexibility is unmatched by traditional scaffolding systems.

- Supports straight, curved, and multi-angle structures easily.

- Adaptable to confined spaces and irregular surfaces.

- Modular nature allows customization for any project size.

2. Speed and Efficiency in Assembly

The wedge locking system allows for quick, tool-light assembly and dismantling. Unlike tube and clamp scaffolding, which requires numerous bolts and nuts, Ringlock scaffolding components slot and lock into place with a hammer.

- Reduces labor time and costs.

- Simplifies training requirements due to intuitive assembly.

- Minimizes human error during setup, enhancing safety.

3. Unmatched Stability and Load Capacity

Ringlock scaffolding is constructed from high-strength steel or aluminum alloys with hot-dip galvanization for corrosion resistance. The lattice formed by the multi-directional rosette connections distributes loads evenly, providing:

- High load-bearing capacity (up to 6 kN/m² or more).

- Superior resistance to wind and dynamic forces.

- Stability even on uneven terrain or in harsh weather.

This makes it suitable for heavy industrial projects, bridges, offshore platforms, and high-rise buildings.

4. Enhanced Safety Features

Safety is a primary concern on construction sites, and Ringlock scaffolding addresses this with:

- Integrated guardrails, midrails, and toe boards that fit seamlessly into the system.

- Anti-slip decking with locking mechanisms to prevent plank displacement.

- Multiple tie-off points for fall arrest systems.

- Reduced risk of accidental disassembly due to wedge locking.

These features help contractors comply with international safety standards such as EN 12811, OSHA, and BS 1139.

5. Long-Term Durability and Cost-Effectiveness

Ringlock scaffolding components are hot-dip galvanized, providing excellent resistance to rust and corrosion, even in marine or industrial environments. This durability translates into:

- A lifespan of 10–25 years with proper maintenance.

- Reduced replacement and repair costs.

- Efficient storage and transport due to modular, stackable components.

Contractors benefit from a lower total cost of ownership compared to traditional scaffolding systems.

Technical Specifications and Standards

When purchasing Ringlock scaffolding, contractors should verify the following specifications:

Specification | Typical Value |

Tube Outer Diameter | 48.3 mm |

Tube Wall Thickness | 3.25 mm |

Rosette Diameter | Approx. 110 mm |

Steel Grade | Q235 / Q345 (S235 / S355) |

Load Capacity | Up to 6 kN/m² or higher |

Surface Treatment | Hot-dip galvanization or electro-galvanization |

Rosette Hole Count | 8 holes (4 large, 4 small) |

Ensure compliance with:

- EN 74-1: European standard for tube and coupler scaffolding

- BS 1139: British standard for scaffolding components

- ISO 9001: Quality management certification

Applications of Ringlock Scaffolding

Ringlock scaffolding's versatility makes it suitable for a wide range of construction projects:

- High-rise buildings with complex facades

- Bridges and infrastructure requiring curved scaffolds

- Industrial plants and offshore platforms needing heavy-duty access

- Temporary roofs and canopies for weather protection

- Event staging and temporary structures

Installation and Maintenance Best Practices

- Use trained personnel for assembly and inspection.

- Always check wedge locks for secure engagement.

- Perform daily inspections for corrosion, damage, or loose components.

- Store components in dry, ventilated areas to prevent rust.

- Replace any worn or damaged parts promptly.

Comparison with Other Scaffolding Systems

Feature | Ringlock Scaffolding | Tube and Clamp | Cuplock System | Kwikstage System |

Assembly Speed | Fast, tool-light | Slow, labor-intensive | Moderate | Moderate |

Load Capacity | High | Variable | Moderate | Moderate |

Flexibility | Multi-angle connections | Highly flexible | Limited angles | Limited angles |

Safety Features | Integrated and robust | Basic | Moderate | Moderate |

Durability | Hot-dip galvanized steel | Varies | Galvanized steel | Galvanized steel |

Additional Advantages of Ringlock Scaffolding

Ease of Transport and Storage

Ringlock scaffolding components are designed to be stackable and compact, making transportation and storage more efficient compared to bulky traditional scaffolding frames. This reduces logistics costs and space requirements on site.

Environmental Benefits

With its durable galvanized finish, Ringlock scaffolding components have a long service life, reducing the need for frequent replacements and minimizing waste. Many manufacturers also use eco-friendly production methods, contributing to sustainable construction practices.

Compatibility with Other Systems

Ringlock scaffolding can often be integrated with other scaffolding types or customized with accessories like stair towers, mobile platforms, and suspended scaffolds, providing contractors with a versatile toolkit for various project needs.

Conclusion

Ringlock scaffolding is preferred by contractors worldwide due to its superior flexibility, rapid assembly, high load capacity, and enhanced safety features. Its modular rosette system allows for complex configurations that traditional scaffolding cannot easily achieve. The system's durability and compliance with international standards make it a cost-effective and reliable choice for a wide variety of construction projects, from high-rise buildings to industrial plants.

Contractors seeking to improve site safety, reduce labor costs, and enhance project efficiency will find Ringlock scaffolding to be an invaluable asset. Investing in quality Ringlock scaffolding ensures safer working conditions and long-term value.

FAQ

1. What makes Ringlock scaffolding safer than traditional scaffolding systems?

Ringlock scaffolding uses a secure wedge-lock rosette system that reduces assembly errors and accidental disassembly, with integrated safety features like guardrails and anti-slip decking.

2. How quickly can Ringlock scaffolding be assembled?

Ringlock scaffolding can be assembled significantly faster than traditional systems, often requiring only a hammer for wedge locking, which reduces labor time and costs.

3. Is Ringlock scaffolding suitable for complex building shapes?

Yes, the rosette connector allows multi-angle connections, making Ringlock scaffolding highly adaptable to curved, sloped, and irregular structures.

4. What materials are used in Ringlock scaffolding components?

Components are typically made from high-strength carbon steel (Q235/Q345) and finished with hot-dip galvanization for corrosion resistance.

5. Can Ringlock scaffolding be customized for specific project needs?

Yes, many manufacturers offer OEM services and customization options for component sizes, finishes, and accessories to meet unique project requirements.