Content Menu

● Understanding Frame Scaffolding Dimensions

● Common Frame Dimensions

● Are Frame Scaffolding Sizes Adjustable?

>> Adjustable Frame Scaffolding Dimensions

>> Examples of Adjustable Frames

● Benefits of Adjustable Frame Scaffolding Dimensions

● Materials and Their Impact on Frame Scaffolding Dimensions

● Load Capacity and Dimension Considerations

● Common Types of Adjustable Frame Scaffolding

● Installation Tips for Adjustable Frame Scaffolding

● Safety Considerations

● Additional Customization Options for Frame Scaffolding Dimensions

>> 1. Modular Frame Extensions

>> 2. Cantilever and Outrigger Systems

>> 3. Adjustable Base Plates and Jacks

>> 4. Custom Platform Sizes

● Advantages of Using Adjustable Frame Scaffolding Systems

● Case Study: Adjustable Frame Scaffolding in Urban Renovation

● Conclusion

● FAQ

>> 1. What are the standard frame scaffolding dimensions?

>> 2. Can frame scaffolding dimensions be customized for irregular building shapes?

>> 3. How does frame scaffolding dimension affect stability?

>> 4. What materials are used in adjustable frame scaffolding?

>> 5. Are there safety standards for adjustable frame scaffolding?

Frame scaffolding systems are among the most commonly used scaffolding types in construction, renovation, and maintenance projects due to their ease of assembly, versatility, and safety. A key question often asked by contractors and site managers is whether frame scaffolding dimensions are adjustable and how this affects their application. This article provides an in-depth exploration of adjustable sizes in frame scaffolding systems, including typical dimensions, customization options, materials, load capacities, and safety considerations.

Understanding Frame Scaffolding Dimensions

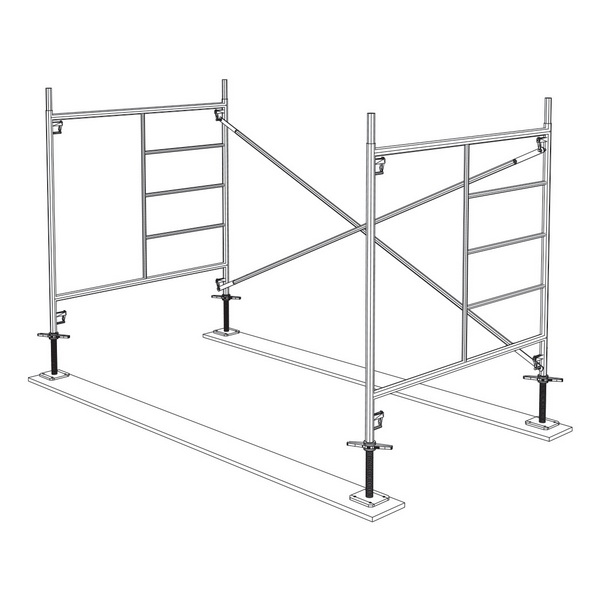

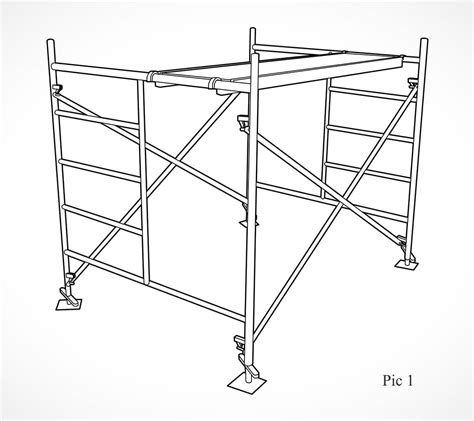

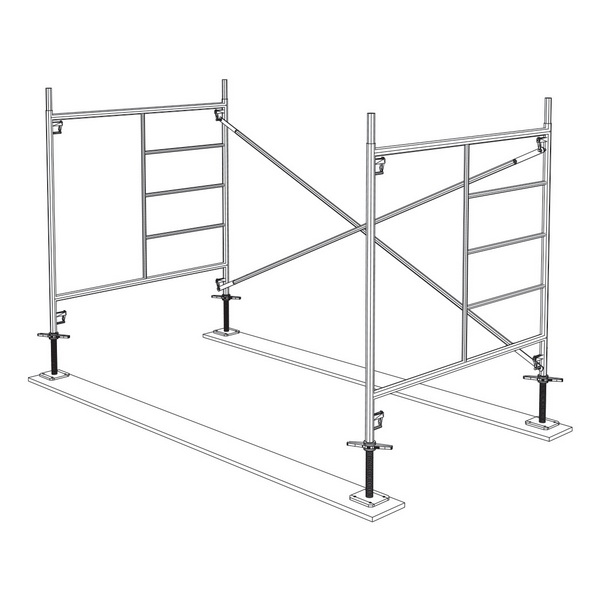

Frame scaffolding dimensions refer to the specific sizes and measurements of the components that make up the scaffolding system. These include the height and width of the frames (standards), the length of cross braces (ledgers and transoms), the size of decking platforms, and the dimensions of base plates and footings.

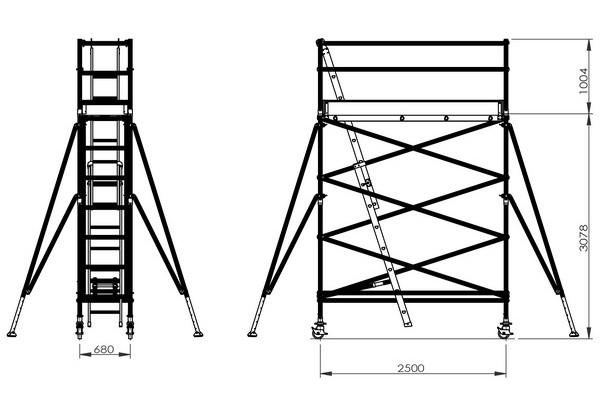

Common Frame Dimensions

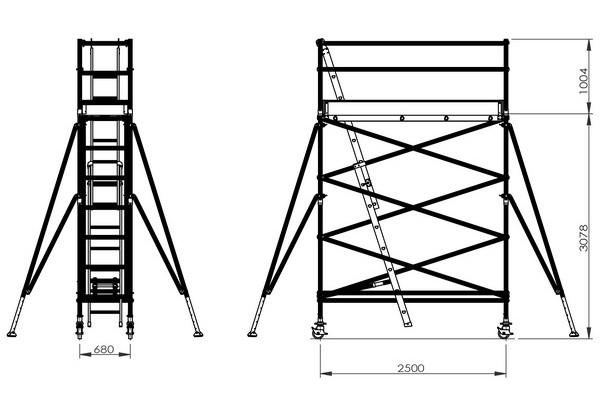

- Height: Standard frame heights range from 1.5 meters to 20 meters or more, with common increments such as 1.5m, 2m, 2.5m, 3m, 4m, 5m, and 6m.

- Width: Frame widths typically vary between 0.6 meters and 2.5 meters, with common widths being 0.6m, 0.9m, 1.2m, and 1.5m.

- Depth: The depth of the scaffolding (distance from the building) is often adjustable through the use of brackets or cantilever arms.

Are Frame Scaffolding Sizes Adjustable?

Adjustable Frame Scaffolding Dimensions

Yes, many frame scaffolding systems offer adjustable sizes to accommodate different project requirements. Adjustable frames allow for:

- Height Adjustment: Some frames come with telescoping or modular sections that can be added or removed to achieve the desired height.

- Width Adjustment: Adjustable width frames or modular attachments enable the scaffold to fit tight or wide spaces.

- Platform Depth Adjustment: By using cantilever brackets, lattice beams, or adjustable ledgers, the depth of the working platform can be extended or shortened.

Examples of Adjustable Frames

- Metaltech Adjustable Frame (60" x 36"/60"): This frame allows width adjustment between 36 inches and 60 inches, providing flexibility for different site conditions.

- Heavy-Duty H-Frame: Often available in sizes like 1.7m x 1.25m but can be combined with modular components to adjust dimensions for specific needs.

Benefits of Adjustable Frame Scaffolding Dimensions

- Versatility: Adjustable frames can be tailored to fit various building shapes and sizes, including irregular facades.

- Space Optimization: Enables scaffolding in confined or complex spaces without compromising safety.

- Cost Efficiency: Reduces the need for multiple frame sizes, simplifying inventory and logistics.

- Improved Safety: Properly adjusted scaffolding dimensions ensure better stability and load distribution.

Materials and Their Impact on Frame Scaffolding Dimensions

Frame scaffolding systems are typically constructed from:

- Steel: Offers high strength and durability, allowing for larger frame dimensions and heavier loads.

- Aluminium: Lightweight and corrosion-resistant, suitable for smaller or mobile scaffolding systems with adjustable frames.

The choice of material influences the maximum adjustable range and load capacity of the scaffolding frames.

Load Capacity and Dimension Considerations

When adjusting frame scaffolding dimensions, it is critical to consider the load capacity:

- Larger frames or extended platforms require higher load ratings.

- The diameter of tubes (commonly 48.3 mm or 60.3 mm) affects strength.

- Proper bracing and base support are essential to maintain stability with adjusted dimensions.

Common Types of Adjustable Frame Scaffolding

- Walk-Through Frames: Often adjustable in width to allow easy passage.

- H-Frames: Modular and can be combined to adjust height and width.

- Ladder Frames: Adjustable height for access and working platforms.

- Cantilever Frames: Allow horizontal adjustment for working platform depth.

Installation Tips for Adjustable Frame Scaffolding

- Always measure the site and plan scaffolding dimensions before assembly.

- Use manufacturer's guidelines for maximum adjustable ranges.

- Ensure all locking pins and couplers are securely fastened after adjustment.

- Regularly inspect adjustable components for wear or loosening.

- Use base jacks to level scaffolding on uneven ground.

Safety Considerations

- Never exceed the rated load capacity for adjusted frame sizes.

- Ensure proper bracing is in place when frames are extended beyond standard dimensions.

- Use guardrails and toe boards on all platforms.

- Train workers on the correct use of adjustable scaffolding components.

- Comply with local safety regulations and standards.

Additional Customization Options for Frame Scaffolding Dimensions

Beyond the basic height and width adjustments, frame scaffolding systems often allow for further customization to meet unique site requirements:

1. Modular Frame Extensions

Modular extensions can be added vertically or horizontally to increase scaffold height or width without replacing entire frames. These extensions are designed to lock securely with existing frames, maintaining structural integrity.

2. Cantilever and Outrigger Systems

Cantilever brackets and outriggers extend the working platform beyond the base frame, allowing access to difficult or recessed areas. These components are adjustable and can be configured to various lengths to suit the job.

3. Adjustable Base Plates and Jacks

Base plates and screw jacks provide fine-tuning of scaffold height at the ground level, compensating for uneven terrain. This adjustment is essential for maintaining scaffold stability and worker safety.

4. Custom Platform Sizes

Platforms and decks come in various sizes and materials, including steel, aluminium, and timber. Adjustable frame scaffolding allows for different platform widths and depths to be installed, depending on the project's needs.

Advantages of Using Adjustable Frame Scaffolding Systems

- Adaptability to Complex Structures: Adjustable frames can be configured to fit around obstacles, corners, and irregular building shapes.

- Reduced Material Waste: By adjusting frame sizes rather than using multiple fixed sizes, material usage is optimized.

- Faster Assembly and Dismantling: Modular and adjustable components simplify the assembly process, saving time on site.

- Enhanced Worker Safety: Properly sized scaffolding reduces hazards related to overreaching or unstable platforms.

Case Study: Adjustable Frame Scaffolding in Urban Renovation

In a recent urban renovation project, adjustable frame scaffolding was employed to navigate narrow alleyways and irregular building facades. The contractor utilized adjustable width frames and cantilever brackets to extend platforms around protruding architectural features. This flexibility allowed work to proceed safely and efficiently without compromising access or stability.

Conclusion

Adjustable sizes for frame scaffolding systems provide essential flexibility for modern construction projects. By allowing modifications in height, width, and platform depth, adjustable frames enable scaffolding to fit a wide range of site conditions and project requirements. When combined with proper materials, load capacities, and safety measures, adjustable frame scaffolding offers a safe, efficient, and cost-effective solution for contractors and builders. Understanding the options for adjusting frame scaffolding dimensions empowers project managers and workers to optimize scaffold design for safety and productivity.

FAQ

1. What are the standard frame scaffolding dimensions?

Standard frame scaffolding dimensions typically range from 1.5m to 6m in height and 0.6m to 1.5m in width, but adjustable frames can vary these sizes to fit specific needs.

2. Can frame scaffolding dimensions be customized for irregular building shapes?

Yes, adjustable frames and modular components allow scaffolding to be tailored to complex or irregular structures.

3. How does frame scaffolding dimension affect stability?

Larger and taller frames require more robust bracing and support to maintain stability; improper sizing can lead to unsafe conditions.

4. What materials are used in adjustable frame scaffolding?

Steel and aluminium are the primary materials, with steel offering higher strength and aluminium providing lightweight portability.

5. Are there safety standards for adjustable frame scaffolding?

Yes, adjustable scaffolding must comply with local and international safety standards such as OSHA, ANSI, and EN 12810 to ensure safe use.