Content Menu

● What is the Cuplock Scaffolding System Manual?

● Is the Cuplock Scaffolding System Manual Beginner-Friendly?

>> 1. Clear and Structured Content

>> 2. Use of Visual Aids

>> 3. Step-by-Step Instructions

>> 4. Safety Information Emphasis

>> 5. Technical Terminology and Accessibility

● Hands-On Training

● Common Challenges Beginners May Face

>> 1. Understanding Technical Details

>> 2. Interpreting Complex Scaffold Layouts

>> 3. Safety Compliance

● Practical Tips for Beginners Using the Cuplock Scaffolding System Manual

● Conclusion

● FAQ

>> 1. Is the cuplock scaffolding system manual suitable for beginners?

>> 2. What safety information does the manual provide?

>> 3. Are there videos available to help beginners understand the manual?

>> 4. How can beginners overcome technical terminology in the manual?

>> 5. Can the manual be used without prior scaffolding experience?

● Citations:

The cuplock scaffolding system is widely recognized for its modular design, ease of assembly, and robust safety features. For beginners, understanding how to erect and use this system safely is essential. The cuplock scaffolding system manual serves as a critical resource, providing detailed instructions, safety information, and technical specifications. This article explores whether beginners can easily use the cuplock scaffolding system manual, highlighting its clarity, structure, and the support materials available.

What is the Cuplock Scaffolding System Manual?

The cuplock scaffolding system manual is a comprehensive guide produced by manufacturers and suppliers to assist users in correctly assembling, using, and maintaining cuplock scaffolding. The manual typically includes:

- An introduction to the system and its components

- Detailed assembly procedures

- Safety guidelines and compliance information

- Diagrams and illustrations of typical scaffold configurations

- Maintenance and inspection recommendations

The manual is designed to comply with international standards such as BS EN 12810 and EN 12811, ensuring users follow best practices for safety and efficiency[1][2][5].

Is the Cuplock Scaffolding System Manual Beginner-Friendly?

1. Clear and Structured Content

The manual is organized logically, starting with an introduction to the cuplock system's unique locking mechanism, followed by component descriptions and step-by-step assembly instructions. For example, the locking procedure is explained clearly:

"The heart of the CUPLOK system is its unique node-point locking device. This enables up to four horizontals to be loosely but safely connected to the standard then locked into position with a single hammer blow. The system uses no loose clips, bolts or wedges"[1][2].

This straightforward explanation helps beginners understand the fundamental working principle before moving on to more complex assembly steps.

2. Use of Visual Aids

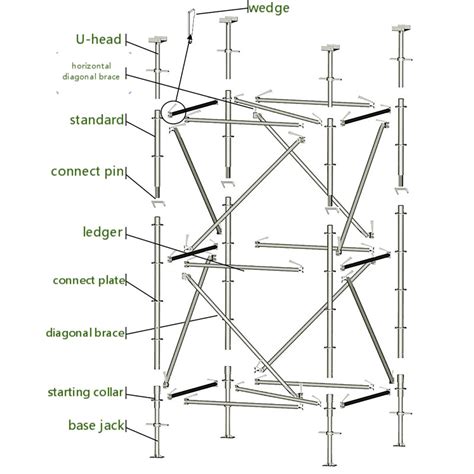

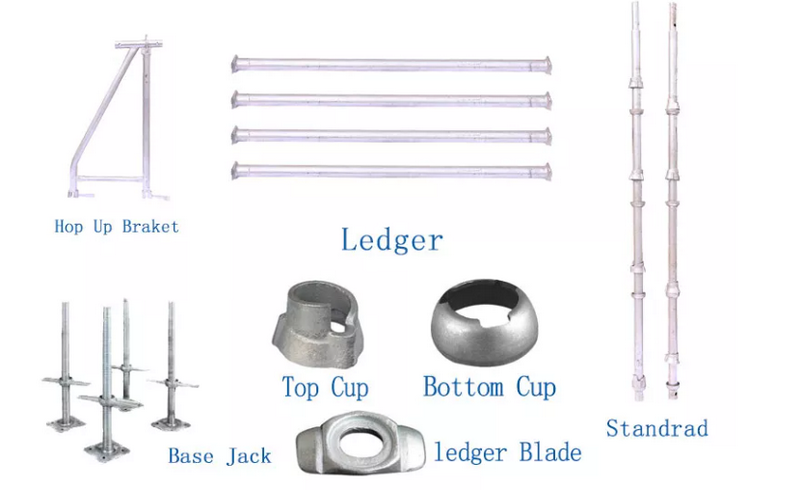

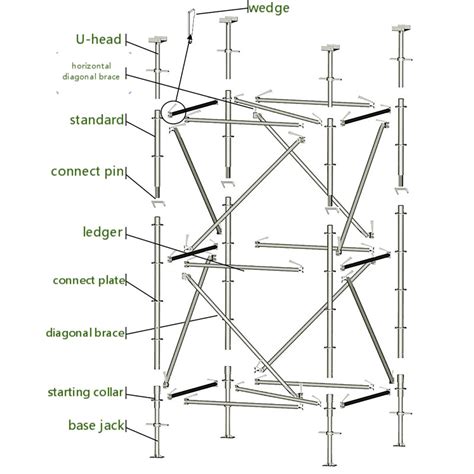

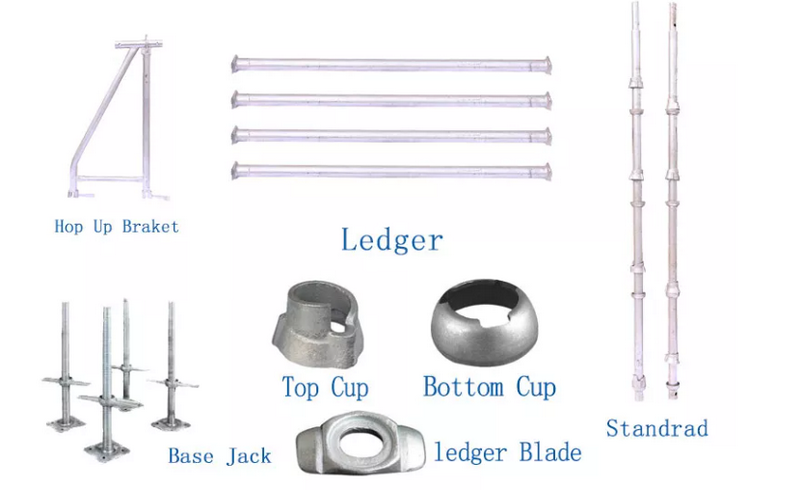

The manual is rich in diagrams, photographs, and layout illustrations that visually guide users through the assembly process. These visuals include:

- Detailed images of the fixed lower cup and rotating upper cup locking mechanism

- Typical scaffold layouts including corner returns and inside board platforms

- Component identification charts showing standards, ledgers, transoms, braces, and base plates

Visual aids reduce ambiguity and help beginners visualize the scaffold structure as they follow the manual[1][2][3].

3. Step-by-Step Instructions

The manual breaks down the assembly into manageable steps, such as:

- Positioning and leveling the base jacks and standards

- Hooking ledgers into the fixed lower cups

- Rotating the upper cups and securing with hammer blows

- Installing diagonal braces and guardrails

This methodical approach supports beginners by guiding them through each phase without overwhelming them with technical jargon[1][6].

4. Safety Information Emphasis

Safety is emphasized throughout the manual, with sections dedicated to:

- Safe working loads on platforms

- Harness requirements and fall protection

- Site safety practices including inspection routines

- Correct use of guardrails and toe boards

Beginners benefit from clear safety protocols that are integrated into the assembly instructions, reinforcing safe work habits from the start[1][2].

5. Technical Terminology and Accessibility

While the manual uses some industry-specific terms (e.g., "node-point," "hop-up brackets," "return devices"), these are explained with accompanying diagrams and context. Beginners with no prior scaffolding experience might initially find some terminology challenging, but the manual's clarity and illustrations help bridge this gap.

Hands-On Training

Many scaffolding companies offer onsite or classroom training sessions where beginners can practice assembling cuplock scaffolding under supervision. This practical experience, combined with the manual, significantly enhances learning and confidence.

Common Challenges Beginners May Face

1. Understanding Technical Details

Some beginners may struggle with technical terms and measurements. However, the manual's clear diagrams and glossary sections help mitigate this.

2. Interpreting Complex Scaffold Layouts

Layouts involving corners, returns, and hop-up brackets can be complex. The manual addresses this with detailed illustrations and multiple layout examples to guide users[1].

3. Safety Compliance

Beginners must pay close attention to safety sections to avoid common mistakes such as improper bracing or missing guardrails.

Practical Tips for Beginners Using the Cuplock Scaffolding System Manual

- Read the entire manual before starting assembly to understand the overall process.

- Use the diagrams as a reference during assembly to ensure correct component placement.

- Follow safety guidelines strictly, including wearing personal protective equipment.

- Practice the locking procedure on a small section to gain confidence before erecting full scaffolds.

- Seek clarification or training if uncertain about any step or terminology.

Conclusion

The cuplock scaffolding system manual is designed to be accessible to users of all skill levels, including beginners. Its clear structure, detailed visual aids, and step-by-step instructions make it an effective tool for learning how to safely and efficiently erect cuplock scaffolding. While some technical terminology may require initial familiarization, supplementary videos and hands-on training further enhance comprehension. By following the manual carefully and adhering to safety guidelines, beginners can confidently use the cuplock scaffolding system to achieve reliable and secure scaffold structures.

FAQ

1. Is the cuplock scaffolding system manual suitable for beginners?

Yes, the manual is structured with clear instructions, diagrams, and safety information to support beginners in understanding and assembling the system[1][2].

2. What safety information does the manual provide?

It includes safe working loads, harness requirements, guardrail installation, and general site safety practices to ensure safe scaffold use[1].

3. Are there videos available to help beginners understand the manual?

Yes, manufacturers and experts provide detailed video tutorials demonstrating the assembly and locking procedures of cuplock scaffolding[1][2].

4. How can beginners overcome technical terminology in the manual?

The manual explains terms with diagrams and context; additional training and videos also help clarify complex concepts[1][6].

5. Can the manual be used without prior scaffolding experience?

While prior experience helps, the manual is designed to be accessible. Beginners should read carefully, use visuals, and seek practical training if needed[3].

Citations:

[1] https://scaffolding-solutions.com.cy/wp-content/uploads/2022/06/user_manual_cuplok_10-2006.pdf

[2] https://www.huennebeck.com/uploads/files/cuplok_system_scaffold_user_guide_en_2015-05-29.pdf

[3] https://www.affixscaffolding.com/wp-content/uploads/2022/03/Affix-Cuplock-Manual.pdf

[4] https://www.seawayscaffold.com/Portals/0/Documents/manuals/Scaffold/Cup%20Lock%20Technical%20Manual.pdf

[5] https://cdn.prod.website-files.com/6723c4704dc317b68172e019/67366167981794e9ead61adf_40489856166.pdf

[6] https://www.scafom-rux.com/en/scaffolding-blog/beginner-s-guide-to-scaffolding-types-the-cuplock-modular-scaffold

[7] https://aaitscaffold.com/wp-content/uploads/2024/02/Cuplock-Product-Manual-AAIT-24-01-2024.pdf