Content Menu

● Understanding the 12 x 16' Aluminum Plank

● Why Customize a 12 x 16' Aluminum Plank?

● Customization Options for 12 x 16' Aluminum Planks

>> 1. Size and Dimension Adjustments

>> 2. Load Capacity Enhancements

>> 3. Surface Treatments and Safety Features

>> 4. Integrated Accessories

● Benefits of Customizing Your Aluminum Plank

● Considerations Before Customizing

>> Material Quality

>> Compliance with Regulations

>> Budget and Lead Time

>> Supplier Expertise

● Examples of Customized 12 x 16' Aluminum Planks in Use

● How to Order a Custom 12 x 16' Aluminum Plank

● Maintenance Tips for Customized Aluminum Planks

● Conclusion

● FAQ

>> 1. Can I change the width of a 12 x 16' aluminum plank?

>> 2. How much extra load can a reinforced custom plank support?

>> 3. Are custom surface treatments like slip-resistant coatings available?

>> 4. How long does it take to receive a customized aluminum plank?

>> 5. Will a custom aluminum plank comply with OSHA and ANSI standards?

A 12 x 16' aluminum plank is a popular choice for scaffolding, staging, and various elevated work platforms due to its lightweight construction, durability, and strength. However, many professionals and project managers often ask: Can I customize a 12 x 16' aluminum plank to better suit my specific project requirements? The answer is yes.

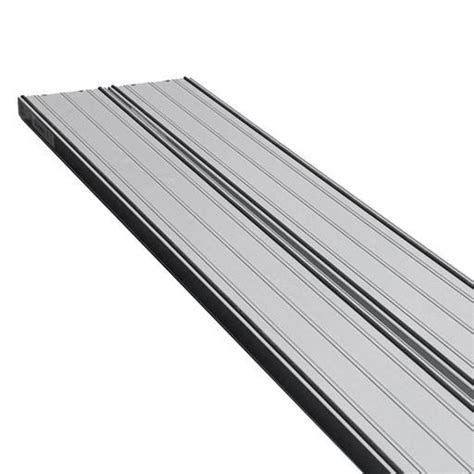

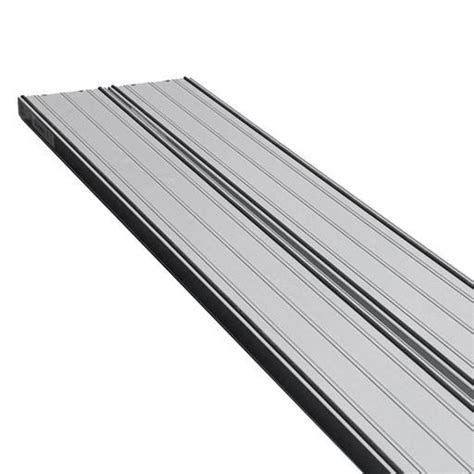

Understanding the 12 x 16' Aluminum Plank

A 12 x 16' aluminum plank typically refers to an aluminum scaffold plank that is 12 inches wide and 16 feet long. These planks are engineered to support significant loads-commonly up to 500 lbs-and are used widely in construction, maintenance, and event staging.

Manufacturers produce these planks with features like slip-resistant surfaces, reinforced edges, and ergonomic handles to enhance safety and usability.

Why Customize a 12 x 16' Aluminum Plank?

Customization allows you to tailor the plank to your project's unique demands, improving safety, efficiency, and functionality. Common reasons for customization include:

- Adjusting dimensions to fit unusual scaffold layouts or confined spaces.

- Enhancing load capacity for heavier equipment or multiple workers.

- Adding safety features like specialized guardrails or anti-slip coatings.

- Modifying surface texture for better traction in wet or oily environments.

- Incorporating handles or attachment points for easier transport and securing.

Customization Options for 12 x 16' Aluminum Planks

1. Size and Dimension Adjustments

While the standard size is 12 inches by 16 feet, manufacturers can often produce planks with:

- Varying widths (e.g., 14", 20", or 24") for wider platforms.

- Custom lengths shorter or longer than 16 feet, depending on structural needs.

- Telescoping or modular designs allowing adjustable length for flexibility.

2. Load Capacity Enhancements

- Use of thicker aluminum alloys or reinforced side channels.

- Addition of internal stiffeners or ribs to increase bending resistance.

- Custom fabrication to meet heavy-duty applications exceeding standard 500 lbs capacity.

3. Surface Treatments and Safety Features

- Slip-resistant coatings or raised tread patterns.

- Powder coating or anodizing for corrosion resistance and aesthetic appeal.

- Integrated drainage slots to prevent water pooling.

- UV-resistant finishes to maintain durability outdoors.

4. Integrated Accessories

- Molded or cast handles for ergonomic lifting.

- Attachment points for securing planks to scaffolding frames.

- Custom end caps to protect plank edges and enhance safety.

- Compatibility with guardrails or toe boards for fall prevention.

Benefits of Customizing Your Aluminum Plank

- Improved Safety: Tailored anti-slip surfaces and guardrails reduce accident risk.

- Enhanced Efficiency: Custom sizes fit your scaffold precisely, minimizing setup time.

- Cost Savings: Reducing material waste by ordering exact dimensions.

- Durability: Specialized coatings and reinforcements extend plank lifespan.

- Versatility: Adaptable to unique project environments and requirements.

Considerations Before Customizing

Material Quality

Ensure the aluminum alloy used meets industry standards (e.g., 6061-T6 or 6063-T6) for strength and corrosion resistance.

Compliance with Regulations

Custom planks must comply with OSHA, ANSI, and local safety standards regarding load capacity, deflection limits, and safety features.

Budget and Lead Time

Customization may increase costs and production time. Balance benefits against project schedules and budgets.

Supplier Expertise

Work with reputable manufacturers experienced in custom aluminum plank fabrication to guarantee quality and safety.

Examples of Customized 12 x 16' Aluminum Planks in Use

- Industrial Maintenance: Planks with reinforced load capacity and chemical-resistant coatings for factory environments.

- Construction Sites: Adjustable-length planks with integrated handles for quick repositioning.

- Event Staging: Wider planks with powder-coated finishes and integrated attachment points for modular stage assembly.

- Marine Applications: Saltwater-resistant anodized planks with drainage slots to prevent corrosion and slipping.

How to Order a Custom 12 x 16' Aluminum Plank

1. Assess Project Requirements: Determine load, size, environment, and safety needs.

2. Consult with Manufacturer: Discuss customization options, materials, and finishes.

3. Request a Quote: Include detailed specifications and quantity.

4. Review Samples or Prototypes: Ensure quality and suitability.

5. Place Order and Schedule Delivery: Coordinate with your project timeline.

Maintenance Tips for Customized Aluminum Planks

- Regularly inspect for damage, corrosion, or wear.

- Clean surfaces to maintain slip resistance.

- Store in dry, sheltered areas to prevent weathering.

- Follow manufacturer guidelines for use and care.

Conclusion

A 12 x 16' aluminum plank can indeed be customized to meet your specific project needs, whether that involves adjusting dimensions, enhancing load capacity, or adding safety features. Customization improves safety, efficiency, and durability, making your scaffolding or staging setup more effective and reliable. Always work with experienced manufacturers and ensure compliance with safety standards to maximize the benefits of your customized aluminum plank.

FAQ

1. Can I change the width of a 12 x 16' aluminum plank?

Yes, many manufacturers offer custom widths ranging from 12" up to 24" or more depending on your requirements.

2. How much extra load can a reinforced custom plank support?

Custom reinforcements can increase load capacity beyond the standard 500 lbs, sometimes up to 750 lbs or more, depending on design.

3. Are custom surface treatments like slip-resistant coatings available?

Absolutely, slip-resistant coatings and textured surfaces are common customization options to enhance safety.

4. How long does it take to receive a customized aluminum plank?

Lead times vary but typically range from 2 to 6 weeks depending on complexity and quantity.

5. Will a custom aluminum plank comply with OSHA and ANSI standards?

When properly designed and fabricated, custom planks can meet or exceed OSHA and ANSI safety requirements.