Content Menu

● What is OEM in the Context of Steel Frame Scaffolding?

● Can You Get OEM Services From a Liba Steel Build Frames Scaffolding System Manufacturers?

● Manufacturing Process of Liba Steel Frame Scaffolding with OEM Customization

>> 1. Design and Engineering

>> 2. Material Selection and Preparation

>> 3. Automated Fabrication

>> 4. Surface Treatment

>> 5. Quality Control and Testing

>> 6. Packaging and Delivery

● Benefits of OEM Services From Liba Steel Build Frames Scaffolding System Manufacturerss

● Additional OEM Customization Options and Industry Trends

● Quality Assurance and Compliance in OEM Production

● How to Choose the Right Liba Steel Build Frames Scaffolding System Manufacturers for OEM?

● Conclusion

● FAQ

>> 1. Can Liba steel build frames scaffolding system Manufacturerss produce fully customized scaffolding?

>> 2. What is the minimum order quantity for OEM services?

>> 3. How long does it take to complete an OEM scaffolding order?

>> 4. Are OEM scaffolding products covered by the same quality standards as regular products?

>> 5. Can OEM Manufacturerss assist with design and engineering?

In the competitive construction industry, customization and branding are key to standing out. Many companies seek Original Equipment Manufacturers (OEM) services to tailor scaffolding products to their specific needs. This article explores whether you can get OEM services from a liba steel build frames scaffolding system Manufacturers, what those services typically include, and how they benefit your business.

What is OEM in the Context of Steel Frame Scaffolding?

OEM (Original Equipment Manufacturers) services involve a Manufacturers producing products that are branded and customized according to the buyer's specifications. For scaffolding, this means a liba steel build frames scaffolding system Manufacturers can produce steel frames, components, and accessories with your company's logo, specific dimensions, finishes, or design modifications.

OEM services allow construction companies, distributors, or contractors to offer unique scaffolding solutions that fit their market demands while leveraging the manufacturing expertise of established Liba scaffolding producers.

Can You Get OEM Services From a Liba Steel Build Frames Scaffolding System Manufacturers?

Yes, Many Liba Manufacturerss Offer OEM Services

Most reputable liba steel build frames scaffolding system Manufacturerss provide OEM services to accommodate client needs. These services include:

- Custom Branding: Adding logos, colors, or company names on scaffolding components.

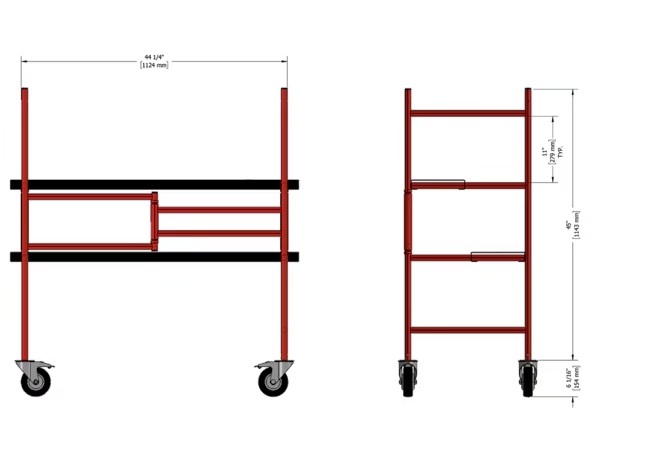

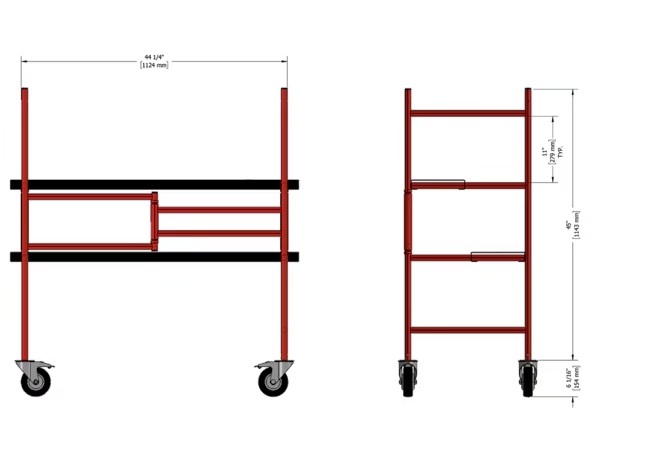

- Tailored Dimensions: Modifying frame sizes, tube diameters, or platform widths.

- Special Finishes: Offering powder coating, galvanizing, or painting in specific colors.

- Accessory Customization: Designing unique couplers, clamps, or decking boards.

- Packaging and Labeling: Customized packaging solutions for easier logistics and brand visibility.

OEM partnerships allow Manufacturerss to produce scaffolding systems that meet unique project requirements or branding strategies.

Manufacturing Process of Liba Steel Frame Scaffolding with OEM Customization

1. Design and Engineering

OEM projects start with detailed discussions on design requirements. Using CAD software, Manufacturerss create precise drawings reflecting client specifications.

- CAD Modeling: Enables visualization and modification before production.

- Structural Analysis: Ensures customized designs meet safety and load standards.

2. Material Selection and Preparation

Liba Manufacturerss use premium steel grades (Q235, Q345) and select coatings based on OEM requests, such as hot-dip galvanizing or powder coating.

3. Automated Fabrication

Advanced machinery, including robotic plasma cutters and CNC welders, fabricate components with high precision.

- Robotic Cutting: Shapes steel tubes and plates accurately.

- Automated Welding: Ensures consistent joint quality.

4. Surface Treatment

Customized surface finishes are applied according to OEM agreements, enhancing corrosion resistance and aesthetics.

- Hot-dip galvanizing for durability.

- Powder coating for color and protection.

- Electroplating for specific requirements.

5. Quality Control and Testing

OEM products undergo rigorous inspections:

- Dimensional checks.

- Weld integrity tests.

- Load capacity verification.

- Visual inspection for coatings and finishes.

6. Packaging and Delivery

Customized packaging solutions ensure safe transport and brand visibility on-site.

Benefits of OEM Services From Liba Steel Build Frames Scaffolding System Manufacturerss

- Brand Differentiation: Stand out with unique, branded scaffolding products.

- Tailored Solutions: Get scaffolding systems designed for specific project needs.

- Quality Assurance: Leverage Liba's manufacturing expertise and quality control.

- Cost Efficiency: Avoid investing in manufacturing infrastructure.

- Supply Chain Simplification: One-stop sourcing of customized scaffolding.

Additional OEM Customization Options and Industry Trends

Beyond basic customization, many liba steel build frames scaffolding system Manufacturerss now offer advanced OEM services aligned with industry trends:

- Integration with Other Scaffolding Systems: Custom fittings compatible with BS standard scaffold pipes, Cuplock accessories, and Layher metric systems enhance versatility.

- Lightweight Aluminum Components: OEM options include aluminum scaffold boards and platforms for easier handling.

- Smart Scaffolding Solutions: Some Manufacturerss incorporate RFID tagging or QR codes on scaffolding parts for inventory management and safety tracking.

- Eco-Friendly Coatings: Use of environmentally friendly powder coatings and reduced VOC paints for sustainability.

These innovations help OEM clients stay competitive and meet evolving market demands.

Quality Assurance and Compliance in OEM Production

Liba steel build frames scaffolding system Manufacturerss maintain strict quality assurance protocols for OEM products to ensure safety and durability:

- Compliance with International Standards: OEM scaffolding products meet EN 12811, OSHA, and JGJ 231-2010 safety standards.

- Third-Party Testing: Independent labs verify load capacity and material strength.

- Traceability: Each OEM batch is traceable for quality control and warranty purposes.

- Continuous Improvement: Feedback loops with OEM clients help refine product design and manufacturing processes.

These measures guarantee that OEM scaffolding systems perform reliably in diverse construction environments.

How to Choose the Right Liba Steel Build Frames Scaffolding System Manufacturers for OEM?

- Check Manufacturers Credentials: Verify certifications and experience in OEM projects.

- Review Past OEM Projects: Ask for samples or case studies.

- Assess Manufacturing Capacity: Ensure they can handle your order volume.

- Evaluate Communication: OEM requires close collaboration.

- Confirm After-Sales Support: Training, spare parts, and warranty services.

Conclusion

OEM services from a liba steel build frames scaffolding system Manufacturers offer construction companies and distributors the flexibility to create tailored, branded scaffolding solutions without investing in manufacturing infrastructure. By leveraging advanced fabrication technologies, strict quality control, and customization options, Liba Manufacturerss ensure that OEM scaffolding products meet the highest standards of durability and safety. Whether you need custom dimensions, finishes, or accessories, partnering with a reputable Liba OEM Manufacturers can enhance your market competitiveness and project efficiency.

FAQ

1. Can Liba steel build frames scaffolding system Manufacturerss produce fully customized scaffolding?

Yes, they can customize dimensions, finishes, accessories, and branding to meet your exact requirements.

2. What is the minimum order quantity for OEM services?

MOQ varies by Manufacturers but typically ranges from a few hundred to several thousand units depending on customization level.

3. How long does it take to complete an OEM scaffolding order?

Lead times depend on order size and complexity but usually range from 4 to 12 weeks.

4. Are OEM scaffolding products covered by the same quality standards as regular products?

Absolutely. OEM products undergo the same rigorous quality control and comply with international safety standards.

5. Can OEM Manufacturerss assist with design and engineering?

Yes, most Liba Manufacturerss offer design support and engineering consultation as part of their OEM services.