Content Menu

● Understanding Girder Clamps

● Key Factors to Consider When Choosing a Girder Clamp

>> Load Capacity

>> Beam Size and Flange Thickness

>> Clamp Type and Design

>> Material and Durability

>> Safety Standards and Certifications

>> Ease of Installation and Use

● Step-by-Step Guide to Choosing the Right Girder Clamp

● Common Mistakes to Avoid

● Maintenance and Inspection

● Conclusion

● FAQ

>> 1. What is the difference between a girder clamp and a beam clamp?

>> 2. How do I determine the load capacity required for my girder clamps?

>> 3. What safety standards should I look for when selecting a girder clamp?

>> 4. Can I use a girder clamp on any type of beam?

>> 5. How often should I inspect my girder clamps?

● Citations:

Choosing the right girder clamp for your scaffolding setup is a critical decision that directly impacts the safety and stability of the entire structure. Girder clamps, also known as beam clamps, are essential components used to attach scaffolding to overhead structural beams, providing a secure and reliable connection point. This article delves into the key factors to consider when selecting a girder clamp, ensuring that your scaffolding setup meets safety standards and effectively supports the intended loads. Properly chosen "scaffolding girder clamp" ensures secure and stable connections to overhead beams.

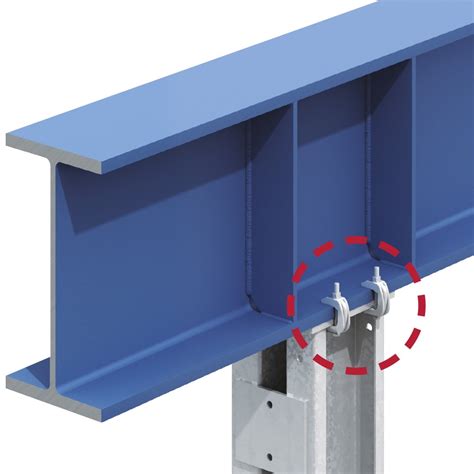

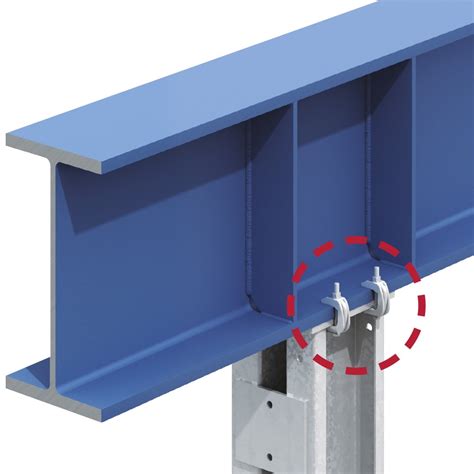

Understanding Girder Clamps

Girder clamps are specialized devices designed to attach scaffolding to structural beams without the need for welding or drilling. They offer a versatile and non-destructive method for creating secure attachment points, making them ideal for various construction, maintenance, and repair applications. These clamps typically consist of a robust frame, a clamping mechanism, and a load-bearing component that connects to the scaffolding structure. The primary advantage of using girder clamps is their ability to distribute loads evenly across the beam flange, minimizing stress concentrations and preventing damage to the structural beam. A solid understanding of "scaffolding girder clamp" types and their load capabilities is fundamental for any scaffolding project.

Key Factors to Consider When Choosing a Girder Clamp

Load Capacity

The load capacity of a girder clamp is the maximum weight it can safely support. This is arguably the most critical factor to consider when selecting a clamp. Always choose a girder clamp with a load capacity that significantly exceeds the maximum anticipated load on the scaffolding. Consider the weight of the scaffolding materials, workers, equipment, and any additional loads that may be applied during the project. Ensure that the clamp's Working Load Limit (WLL) is clearly marked and that you understand the safety factor applied by the manufacturer. Understanding the "scaffolding girder clamp" load ratings prevents overloading and potential structural failures.

Beam Size and Flange Thickness

Girder clamps are designed to fit specific beam sizes and flange thicknesses. Using a clamp that is too small or too large can compromise the connection and lead to instability. Measure the beam's flange width and thickness accurately to ensure a proper fit. Many manufacturers provide charts and specifications that detail the compatible beam sizes for their clamps. Some clamps are adjustable to accommodate a range of beam sizes, providing greater flexibility. Selecting the right size "scaffolding girder clamp" for the beam is essential for secure attachment.

Clamp Type and Design

Different types of girder clamps are available, each suited for specific applications. Common types include:

1. Fixed Jaw Girder Clamps: These clamps have a fixed jaw opening and are ideal for beams with consistent flange thicknesses.

2. Adjustable Jaw Girder Clamps: These clamps feature an adjustable jaw that can accommodate a range of beam sizes, providing greater versatility.

3. Swivel Girder Clamps: These clamps have a swivel mechanism that allows for angled connections, useful for scaffolding setups that require flexibility.

4. Locking Girder Clamps: These clamps incorporate a locking mechanism to prevent accidental disengagement, enhancing safety.

The choice of clamp type depends on the specific requirements of your scaffolding setup. For heavy-duty applications, consider using locking or heavy-duty adjustable clamps. The specific design of the "scaffolding girder clamp" affects its suitability for different beam configurations.

Material and Durability

Girder clamps used in scaffolding should be constructed from high-strength materials such as steel or malleable iron. These materials offer excellent durability and resistance to corrosion, ensuring that the clamps can withstand the harsh conditions of a construction site. Choose clamps with a protective coating, such as zinc plating or powder coating, to further enhance their resistance to rust and environmental damage. Regular inspections should be performed to check for any signs of wear, damage, or corrosion. Durable materials ensure that the "scaffolding girder clamp" maintains its integrity over time.

Safety Standards and Certifications

Ensure that the girder clamps you select comply with relevant safety standards and certifications. Look for clamps that meet or exceed OSHA (Occupational Safety and Health Administration) regulations, ANSI (American National Standards Institute) standards, and other applicable industry standards. These certifications indicate that the clamps have been tested and verified to meet specific performance and safety requirements. Compliance with safety standards ensures the "scaffolding girder clamp" meets industry safety benchmarks.

Ease of Installation and Use

Consider the ease of installation and use when selecting a girder clamp. Clamps that are easy to install and adjust can save time and reduce the risk of errors. Look for clamps with clear instructions and user-friendly designs. Some clamps feature quick-release mechanisms that allow for rapid installation and removal. Proper training should be provided to workers on the correct installation and use of girder clamps. User-friendly designs improve the efficiency of using "scaffolding girder clamp" in the field.

Step-by-Step Guide to Choosing the Right Girder Clamp

1. Assess Load Requirements: Determine the maximum anticipated load on the scaffolding, including materials, workers, and equipment.

2. Measure Beam Dimensions: Accurately measure the beam's flange width and thickness.

3. Select Clamp Type: Choose the appropriate clamp type based on the beam configuration and scaffolding requirements.

4. Verify Load Capacity: Ensure that the clamp's load capacity exceeds the maximum anticipated load.

5. Check Material and Durability: Select clamps constructed from high-strength materials with a protective coating.

6. Confirm Safety Standards: Verify that the clamps comply with relevant safety standards and certifications.

7. Evaluate Ease of Use: Consider the ease of installation and adjustment.

8. Consult with Experts: If necessary, consult with a qualified engineer or scaffolding expert.

Following these steps ensures that the "scaffolding girder clamp" is appropriate for the intended use.

Common Mistakes to Avoid

- Overloading the Clamp: Exceeding the clamp's load capacity can lead to failure and collapse.

- Using the Wrong Size: Using a clamp that is too small or too large can compromise the connection.

- Neglecting Inspections: Failing to regularly inspect clamps can result in undetected damage or wear.

- Improper Installation: Incorrectly installing the clamp can reduce its effectiveness and increase the risk of accidents.

- Ignoring Safety Standards: Neglecting to comply with safety standards can lead to fines, project delays, and injuries.

Avoiding these mistakes is essential for maintaining the safety and stability of scaffolding structures. Careful attention to the selection and use of "scaffolding girder clamp" minimizes risks on the job site.

Maintenance and Inspection

Regular maintenance and inspection are essential for ensuring the continued safety and reliability of girder clamps. Inspect clamps before each use for signs of wear, damage, or corrosion. Check the screw mechanism for smooth operation and lubricate as needed. Replace any clamps that are cracked, deformed, or otherwise compromised. Keep clamps clean and store them in a dry place to prevent rust and corrosion. Routine maintenance extends the lifespan of the "scaffolding girder clamp" and ensures safe operation.

Conclusion

Choosing the right girder clamp for your scaffolding setup is a critical decision that requires careful consideration of load capacity, beam size, clamp type, material, safety standards, and ease of use. By following the guidelines outlined in this article and avoiding common mistakes, you can ensure that your scaffolding structure is safe, stable, and compliant with industry regulations. Prioritize safety and consult with experts when needed to create a secure working environment for your construction projects. The appropriate "scaffolding girder clamp" is vital for a secure and efficient scaffolding system.

FAQ

1. What is the difference between a girder clamp and a beam clamp?

Girder clamp and beam clamp are often used interchangeably. Both refer to devices that attach to structural beams without welding or drilling.

2. How do I determine the load capacity required for my girder clamps?

Assess the maximum anticipated load on the scaffolding, including materials, workers, and equipment. Choose a clamp with a WLL that exceeds this load.

3. What safety standards should I look for when selecting a girder clamp?

Look for clamps that meet or exceed OSHA regulations, ANSI standards, and other applicable industry standards.

4. Can I use a girder clamp on any type of beam?

Girder clamps are designed for specific beam sizes and flange thicknesses. Ensure that the clamp is compatible with the beam you are using.

5. How often should I inspect my girder clamps?

Girder clamps should be inspected before each use for signs of wear, damage, or corrosion.

Citations:

[1] https://www.tp-scaffold.com/how-do-i-choose-the-right-girder-clamp-for-my-scaffolding-setup.html

[2] https://brandsafway.com/uploads/files/orn401_bsl_tube_and_clamp_product_brochure.pdf

[3] https://www.altradgeneration.com/assets/files/guides_and_documents/scaffolding/scaffold-coupler-manual.pdf

[4] https://www.acrow.com.au/wp-content/uploads/2020/11/couplers-product-guide.pdf

[5] https://www.tp-scaffold.com/how-to-choose-the-best-scaffolding-beam-clamp-for-your-project.html

[6] https://rlsdhamal.com/scaffolding-couplers-working-load-capacity/

[7] https://firstfence.co.uk/girder-clamps

[8] https://www.linkedin.com/pulse/maximizing-efficiency-ultimate-guide-using-girder-load-elkholly

[9] https://www.gd-scaffold.com/news/understanding-the-load-capacity-of-scaffolding-clamps.html

[10] https://www.londonscaffoldingsupplies.co.uk/scaffold-gravlock-girder-beam-clamps/