Content Menu

● Key Components of H Frame Scaffolding

● How Does H Frame Scaffolding Work?

● Step-by-Step Assembly Process

● Advantages of H Frame Scaffolding

● Applications of H Frame Scaffolding

● Safety Considerations for H Frame Scaffolding

● Maintenance and Inspection

● Technical Specifications

● Innovations in H Frame Scaffolding

● Conclusion

● FAQ

>> 1. What materials are used to make H frame scaffolding?

>> 2. How high can H frame scaffolding be safely erected?

>> 3. Can H frame scaffolding be used on uneven ground?

>> 4. What safety features are essential for H frame scaffolding?

>> 5. How long does it take to assemble H frame scaffolding?

● Citations:

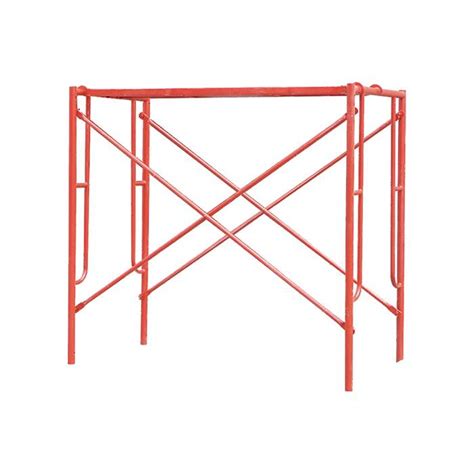

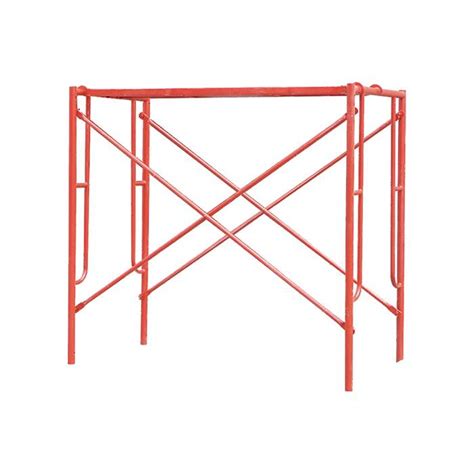

H frame scaffolding consists of vertical frames shaped like the letter "H," connected by horizontal and diagonal braces. These frames form the backbone of the scaffolding system, providing vertical support and lateral stability. The system is modular, allowing for quick assembly and disassembly, making it ideal for a variety of construction and maintenance projects.

Key Components of H Frame Scaffolding

- H Frames: The primary vertical structures, each shaped like an "H," consisting of two vertical tubes connected by a horizontal crossbar.

- Cross Bracing: Diagonal braces that connect the vertical frames, preventing lateral movement and sway.

- Single Bracing: Horizontal braces that add extra reinforcement between frames.

- Plan Bracing: Horizontal braces parallel to the working platform, distributing weight evenly.

- Tie Bracing: Connects the scaffold to the building or structure, preventing it from leaning or swaying.

- Base Plates and Screw Jacks: Provide a stable foundation and allow height adjustment on uneven ground.

- Platforms/Decks: Wooden or metal planks where workers stand.

- Guardrails and Toe Boards: Safety features to prevent falls and falling objects.

- Pins, Clips, and Couplers: Secure all components together.

How Does H Frame Scaffolding Work?

The working principle of h frame scaffolding is based on creating a rigid, stable structure by interlocking the H-shaped frames with braces and platforms. The frames bear the vertical load, while the braces prevent lateral movement, ensuring the scaffold remains steady under the weight of workers and materials.

Step-by-Step Assembly Process

1. Select a Stable Foundation:

Choose a flat, firm surface free of debris. Use base plates and adjustable screw jacks to level the scaffold on uneven ground.

2. Lay Out Components:

Organize all parts—H frames, cross braces, single braces, plan braces, tie braces, platforms, and safety equipment.

3. Position H Frames:

Stand the vertical H frames upright, parallel to each other, with the wider section facing outward.

4. Attach Cross Bracing:

Connect diagonal cross braces between the vertical frames, forming an "X" pattern to prevent sway.

5. Install Single and Plan Bracing:

Add horizontal braces between frames to reinforce the structure and support the platforms.

6. Secure Tie Bracing:

Attach tie braces to anchor the scaffold to the adjacent building or structure, enhancing stability.

7. Place Platforms:

Lay wooden or metal planks on the horizontal ledgers to create safe working surfaces.

8. Add Guardrails and Toe Boards:

Install safety rails and toe boards around platforms to protect workers.

9. Final Inspection:

Check all connections, braces, and platforms for security and stability before use.

Advantages of H Frame Scaffolding

- Simplicity: The modular design allows for quick assembly and disassembly without specialized tools.

- Stability: Cross and tie bracing provide excellent lateral support, reducing sway.

- Versatility: Suitable for various applications including building construction, maintenance, painting, and industrial work.

- Cost-Effectiveness: Prefabricated components reduce labor costs and material waste.

- Safety: Meets international safety standards with options for guardrails, toe boards, and secure locking mechanisms.

- Portability: Components are lightweight and easy to transport.

Applications of H Frame Scaffolding

- Building Construction: Provides safe access for workers on multi-story buildings.

- Bridge Maintenance: Offers stable platforms for inspection and repair.

- Painting and Plastering: Ensures steady working surfaces for surface treatments.

- Industrial Facilities: Used for maintenance and installation tasks.

- Event Staging: Temporary platforms for lighting, sound, and stage setup.

Safety Considerations for H Frame Scaffolding

- Compliance: Follow OSHA, ANSI, and EN standards for load capacity and worker safety.

- Regular Inspections: Check for damaged frames, loose braces, and secure fasteners.

- Proper Training: Workers must be trained in assembly, use, and emergency procedures.

- Use of PPE: Helmets, harnesses, and non-slip footwear are essential.

- Load Management: Avoid overloading platforms beyond specified limits.

- Stable Base: Ensure base plates and jacks are properly positioned and adjusted.

- Weather Awareness: Avoid scaffold use during high winds or adverse weather.

Maintenance and Inspection

Routine maintenance extends the life of H frame scaffolding and ensures safety:

- Clean components to prevent rust and dirt buildup.

- Store parts in dry, covered areas.

- Replace damaged or worn parts immediately.

- Lubricate adjustable jacks for smooth operation.

- Conduct pre-use inspections daily.

Technical Specifications

- Frame Height: Typically 2 meters per frame.

- Frame Width: Usually 2.5 meters between frames.

- Material: High-quality steel or aluminum for durability.

- Load Capacity: Varies by manufacturer, generally suitable for medium loads.

- Adjustability: Screw jacks allow height adjustments for uneven terrain.

Innovations in H Frame Scaffolding

- Digital Design Tools: Software for planning scaffold layouts and load distribution.

- Lightweight Alloys: New materials reduce weight without sacrificing strength.

- Modular Accessories: Integrated ladders, tool trays, and adjustable guardrails.

- Safety Sensors: Real-time monitoring of structural integrity.

Conclusion

H frame scaffolding is a fundamental system in construction, offering a balance of simplicity, safety, and versatility. Its modular "H" shaped frames combined with cross and tie bracing create a stable platform for workers to perform tasks at height efficiently. Whether for building construction, maintenance, or industrial applications, H frame scaffolding provides a cost-effective and reliable solution.

By understanding its components, assembly process, and safety requirements, construction professionals can maximize productivity while minimizing risks. With ongoing innovations and strict adherence to safety standards, H frame scaffolding will continue to be a cornerstone of safe and efficient construction practices.

FAQ

1. What materials are used to make H frame scaffolding?

H frame scaffolding is typically made from high-quality steel or aluminum, providing strength and durability while allowing for portability and ease of assembly.

2. How high can H frame scaffolding be safely erected?

Generally, H frame scaffolding is suitable for heights up to about 30 feet (approximately 9 meters). For taller structures, additional safety measures or different scaffolding systems may be required.

3. Can H frame scaffolding be used on uneven ground?

Yes, adjustable screw jacks and base plates allow the scaffold to be leveled on uneven surfaces, ensuring stability and safety.

4. What safety features are essential for H frame scaffolding?

Guardrails, toe boards, secure locking pins, and tie bracing to the building are essential safety features to prevent falls and structural instability.

5. How long does it take to assemble H frame scaffolding?

Due to its modular design, H frame scaffolding can be assembled quickly, often within a few hours depending on the size and complexity of the project.

Citations:

[1] https://primesteeltech.co.in/h-frame-scaffolding-systems-a-comprehensive-guide.html

[2] https://apacsafety.com/comprehensive-guide-to-h-frame-scaffolding/

[3] https://msafegroup.com/h-frame-scaffolding-systems-a-detailed-manual/

[4] https://www.youtube.com/watch?v=utWWhtZBT2o

[5] https://mrctas.org.au/wp-content/uploads/2020/07/Module-H-Scaffolding.pdf

[6] https://www.youtube.com/watch?v=PD0G6zD0R4M

[7] https://primesteeltech.co.in/understanding-the-h-frame-scaffolding-solution-for-efficiency-and-flexibility.html

[8] https://www.youtube.com/watch?v=HqZ6cqqyBnQ

[9] https://www.youtube.com/watch?v=uMGaoEVNUyE

[10] https://stock.adobe.com/search/images?k=h-frame

[11] https://www.shutterstock.com/search/main-frame-scaffolding