Content Menu

● Overview of 14 x 24' Aluminum Planks

● Weight and Load Capacity of 14 x 24' Aluminum Planks

● Steel Planks: Weight and Strength Overview

● Comparative Table: Aluminum vs. Steel 14 x 24' Planks

● Factors Influencing Plank Weight and Performance

>> Material Thickness and Alloy

>> Design and Reinforcement

>> Surface Treatment

● Practical Implications of Weight Differences

>> Handling and Installation

>> Transportation and Storage

>> Safety Considerations

● Applications Best Suited for Each Material

>> Aluminum Planks

>> Steel Planks

● Conclusion

● FAQ

>> 1. How much does a 14 x 24' aluminum plank weigh?

>> 2. What is the load capacity of a 14 x 24' aluminum plank?

>> 3. How does the weight of aluminum planks compare to steel?

>> 4. Are aluminum planks as durable as steel?

>> 5. Which plank is better for outdoor use?

When selecting scaffolding planks for construction, maintenance, or event staging, the choice of material significantly impacts safety, ease of use, and project efficiency. The 14 x 24' aluminum plank is a widely used option, prized for its lightweight and corrosion resistance. However, steel planks remain popular for their strength and durability.

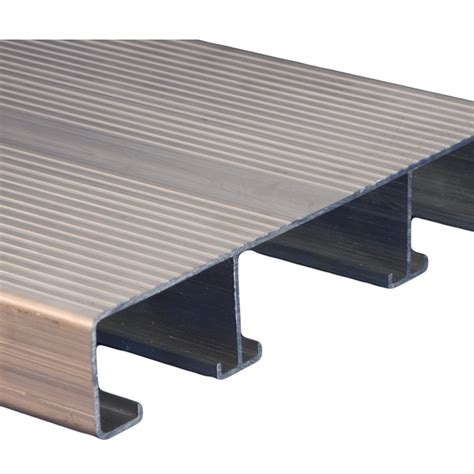

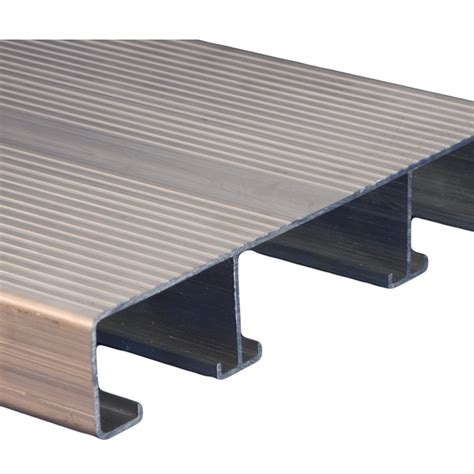

Overview of 14 x 24' Aluminum Planks

A 14 x 24' aluminum plank typically measures 14 inches in width and 24 feet in length. These planks are designed to support up to 500 lbs, accommodating two workers and their tools safely. They are constructed from high-grade aluminum alloys, often with slip-resistant surfaces and reinforced edges.

- Weight: Approximately 93.7 lbs (42.5 kg) for a 14" x 24' aluminum plank as per Metaltech specifications.

- Load Capacity: Rated for 500 lbs, OSHA and ANSI compliant.

- Applications: Ladder jacks, swing stages, catwalks, and scaffolding platforms.

Weight and Load Capacity of 14 x 24' Aluminum Planks

The lightweight nature of aluminum is a key advantage. For example, the Titan Aluminum Stage 14" x 24' plank weighs about 93.7 lbs while supporting 500 lbs.This weight allows for easier handling, transport, and installation compared to steel planks of similar size.

- Typical Aluminum Plank Weight Range: 90-100 lbs for 14" x 24' planks.

- Load Capacity: Consistently rated at 500 lbs for two workers.

Steel Planks: Weight and Strength Overview

Steel planks, while heavier, offer higher strength and durability. A 14 x 24' steel plank can weigh significantly more than an aluminum plank, often exceeding 150 lbs depending on gauge and design.

- Weight: Steel planks of similar dimensions can weigh between 150 to 250 lbs.

- Load Capacity: Steel planks often support higher loads, sometimes over 750 lbs.

- Durability: Steel is less prone to bending under heavy loads but susceptible to corrosion without proper coating.

Comparative Table: Aluminum vs. Steel 14 x 24' Planks

| Feature | 14 x 24' Aluminum Plank | 14 x 24' Steel Plank |

| Approximate Weight | ~93.7 lbs (42.5 kg) | 150-250 lbs (68-113 kg) |

| Load Capacity | 500 lbs (227 kg) | 750+ lbs (340+ kg) |

| Corrosion Resistance | Excellent (galvanized/anodized) | Requires coating or galvanizing |

| Ease of Handling | Lightweight, easy to move | Heavy, requires more effort |

| Maintenance | Low | Higher (rust prevention needed) |

| Cost | Generally higher upfront | Lower upfront, higher maintenance |

Factors Influencing Plank Weight and Performance

Material Thickness and Alloy

- Aluminum planks use alloys like 6061-T6 for strength and lightness.

- Steel planks vary in gauge; thicker steel increases weight but improves load capacity.

Design and Reinforcement

- Aluminum planks often include reinforced edges and stiffeners to improve rigidity without adding much weight.

- Steel planks may be solid or have perforations to reduce weight while maintaining strength.

Surface Treatment

- Aluminum planks are often anodized or powder-coated for corrosion resistance.

- Steel planks require galvanization or paint to prevent rust.

Practical Implications of Weight Differences

Handling and Installation

- Aluminum planks' lighter weight reduces labor fatigue and risk of injury.

- They allow quicker scaffold assembly and repositioning.

- Steel planks require more manpower or mechanical assistance.

Transportation and Storage

- Aluminum planks reduce shipping costs due to lighter weight.

- Easier storage and stacking because of lower weight.

Safety Considerations

- Both materials meet safety standards if used within load limits.

- Aluminum's corrosion resistance reduces slip hazards caused by rust.

- Steel's higher weight can provide extra stability but may increase injury risk during handling.

Applications Best Suited for Each Material

Aluminum Planks

- Residential and commercial construction.

- Maintenance and repair work requiring frequent relocation.

- Outdoor projects where corrosion resistance is critical.

- Events and temporary staging.

Steel Planks

- Heavy industrial applications.

- Projects requiring maximum load capacity.

- Environments with minimal exposure to moisture or with proper rust protection.

- Long-term installations where durability outweighs weight concerns.

Conclusion

A 14 x 24' aluminum plank typically weighs around 93.7 lbs, significantly lighter than comparable steel planks which can weigh between 150 and 250 lbs. While steel offers higher load capacity and durability, aluminum planks provide excellent corrosion resistance, easier handling, and faster installation, making them ideal for many construction and maintenance applications. Choosing between aluminum and steel depends on your project's specific needs including load requirements, environmental conditions, and labor resources.

FAQ

1. How much does a 14 x 24' aluminum plank weigh?

Approximately 93.7 lbs (42.5 kg), depending on manufacturer and design.

2. What is the load capacity of a 14 x 24' aluminum plank?

Typically rated for 500 lbs, suitable for two workers and their tools.

3. How does the weight of aluminum planks compare to steel?

Aluminum planks are about 40-60% lighter than steel planks of the same size.

4. Are aluminum planks as durable as steel?

Aluminum is highly corrosion-resistant and durable but may bend more under extreme loads compared to steel.

5. Which plank is better for outdoor use?

Aluminum planks are generally better due to superior corrosion resistance.