Content Menu

● What Is a 12 Aluminum Plank?

● Standard Load Capacity of 12 Aluminum Planks

● Factors Affecting Load Capacity

>> 1. Plank Length

>> 2. Support Spacing

>> 3. Material and Construction

>> 4. Load Distribution

● Industry Standards and Safety Regulations

>> OSHA Requirements

>> ANSI and EN Standards

● Real-World Applications of 12 Aluminum Planks

● Comparing 12 Aluminum Planks to Other Materials

● Maintenance and Inspection Tips

● Additional Considerations for Safe Use

>> Proper Installation

>> Environmental Factors

>> Load Management

● Conclusion

● FAQ

>> 1. What is the maximum weight a 12 aluminum plank can support?

>> 2. Does the length of the plank affect its load capacity?

>> 3. Are 12 aluminum planks slip-resistant?

>> 4. How often should aluminum planks be inspected?

>> 5. Can 12 aluminum planks be used outdoors?

When working at heights, safety and reliability are paramount, especially regarding the platforms workers stand on. The 12 aluminum plank is a popular choice in scaffolding and staging due to its lightweight nature, durability, and strength. However, understanding how much weight a 12 aluminum plank can support is crucial for ensuring safety and compliance with regulations.

What Is a 12 Aluminum Plank?

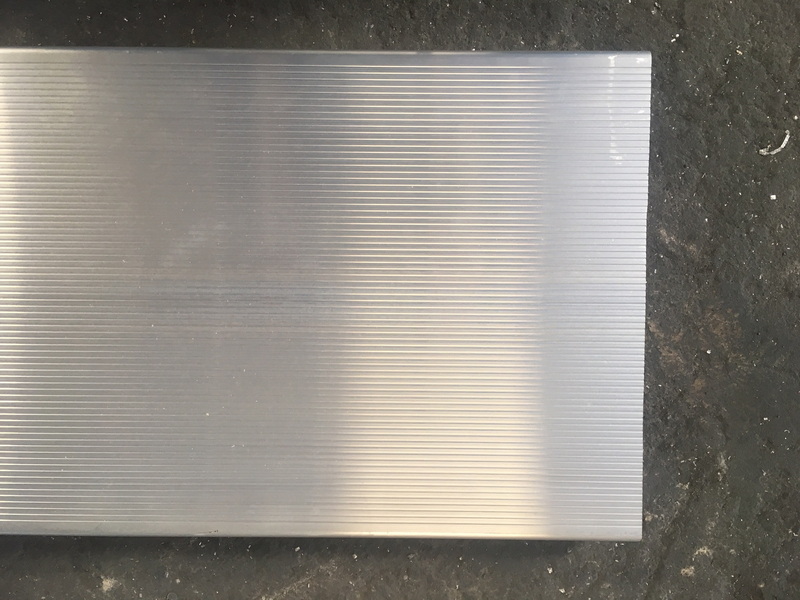

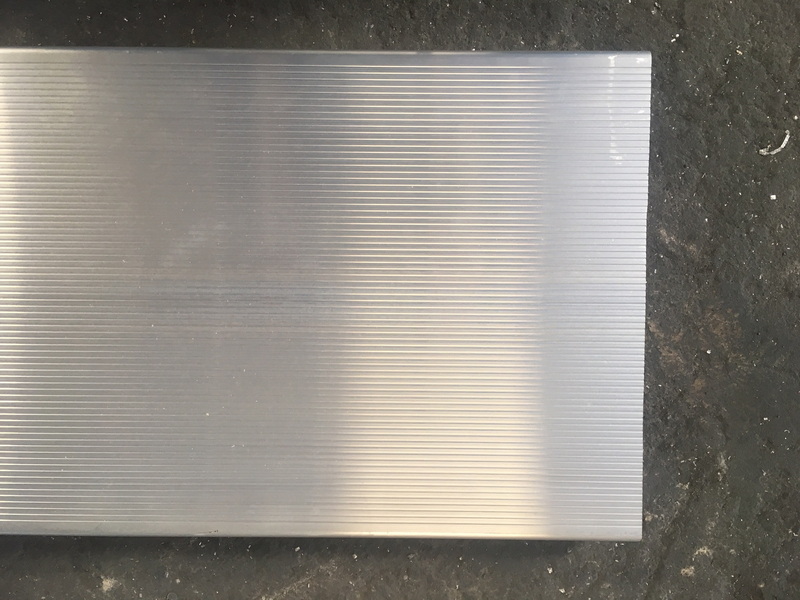

A 12 aluminum plank typically refers to an aluminum scaffold plank that is 12 inches wide. These planks are used as working platforms on scaffolding systems, ladder jacks, swing stages, or catwalks. They combine lightweight properties with high strength, making them ideal for various construction and maintenance tasks.

Standard Load Capacity of 12 Aluminum Planks

Most 12 aluminum planks on the market are rated to support a maximum load of 500 pounds (approximately 227 kilograms). This rating generally accommodates two workers and their tools or materials safely.

- Examples:

- Louisville Ladder's 12-foot aluminum scaffold plank supports up to 500 lbs.

- Werner's 12-inch wide aluminum stage plank also has a 500 lb load capacity.

- Badger Ladder's 12” wide aluminum stages are OSHA-approved for 1-2 workers with a 500 lb capacity.

Factors Affecting Load Capacity

1. Plank Length

The length of the plank affects its bending and deflection under load. Longer planks may have lower load capacity or require additional support.

- Common lengths range from 12 feet to 24 feet.

- For example, a 12 ft plank may support 500 lbs, whereas longer planks might have reduced capacity or require extra bracing.

2. Support Spacing

The distance between supports (such as scaffold frames or ladder jacks) influences the plank's ability to carry weight.

- Typical maximum support spacing is 6 feet.

- Closer supports reduce bending and increase load capacity.

3. Material and Construction

- High-quality aluminum alloys provide strength and corrosion resistance.

- Planks often feature reinforced edges or flanges to increase rigidity.

- Some planks include slip-resistant surfaces for safety.

4. Load Distribution

- Uniformly distributed loads are safer than point loads.

- OSHA guidelines specify different load ratings for uniformly distributed vs. concentrated loads.

Industry Standards and Safety Regulations

OSHA Requirements

OSHA requires scaffold planks to support at least four times the maximum intended load without failure. For a 12 aluminum plank rated at 500 lbs, this means it should withstand at least 2000 lbs in testing.

ANSI and EN Standards

- ANSI and EN standards specify design and testing criteria for scaffold planks.

- Compliance ensures planks meet minimum strength and deflection limits.

Real-World Applications of 12 Aluminum Planks

- Construction: Used on scaffolds for masonry, painting, and finishing work.

- Maintenance: Ideal for access platforms in industrial settings.

- Events: Temporary stages and catwalks.

- DIY Projects: Home renovations requiring safe elevated platforms.

Comparing 12 Aluminum Planks to Other Materials

| Material | Weight | Load Capacity | Durability | Cost |

| Aluminum Plank | Lightweight | ~500 lbs (12 ft) | Corrosion resistant | Moderate to high |

| Wood Plank | Heavier | Varies, often less | Prone to rot | Lower |

| Steel Plank | Heavy | Higher load capacity | Rust prone | Higher |

Maintenance and Inspection Tips

- Inspect planks regularly for dents, cracks, or corrosion.

- Clean surfaces to maintain slip resistance.

- Store planks in dry, covered areas.

- Replace damaged planks immediately.

Additional Considerations for Safe Use

Proper Installation

- Ensure the plank is properly seated on scaffold frames or supports.

- Avoid overhanging unsupported lengths beyond manufacturer recommendations.

- Use locking mechanisms or clamps if available to prevent movement.

Environmental Factors

- Aluminum planks perform well in wet or corrosive environments but always check for surface contaminants that may cause slipping.

- In cold weather, aluminum maintains strength but can become slick; use anti-slip coatings or mats.

Load Management

- Do not overload the plank beyond its rated capacity.

- Distribute materials evenly to avoid point loading.

- Consider dynamic loads such as workers moving or carrying heavy tools.

Conclusion

A 12 aluminum plank typically supports up to 500 pounds, making it suitable for two workers and their tools. However, actual load capacity depends on plank length, support spacing, material quality, and load distribution. Compliance with OSHA and ANSI standards ensures safety and reliability. Proper maintenance and inspection extend plank life and maintain safe working conditions. Understanding these factors helps users select and use 12 aluminum planks confidently and safely.

FAQ

1. What is the maximum weight a 12 aluminum plank can support?

Most 12 aluminum planks support up to 500 lbs, suitable for two workers plus equipment.

2. Does the length of the plank affect its load capacity?

Yes, longer planks may require additional support or have reduced load ratings.

3. Are 12 aluminum planks slip-resistant?

Many feature slip-resistant surfaces to improve safety, but this varies by manufacturer.

4. How often should aluminum planks be inspected?

Before each use and regularly for signs of damage or wear.

5. Can 12 aluminum planks be used outdoors?

Yes, they are corrosion-resistant and suitable for outdoor scaffolding applications.