Content Menu

● Understanding Ringlock Scaffolding Brackets

>> What Is a Ringlock Scaffolding Bracket?

>> Types of Ringlock Scaffolding Brackets

>> Board Bracket Options

● Key Factors to Consider When Choosing a Ringlock Scaffolding Bracket

>> 1. Compatibility with Scaffold Decks

>> 2. Load Capacity and Safety

>> 3. Material and Surface Treatment

>> 4. Project-Specific Requirements

>> 5. Ease of Installation and Versatility

● Detailed Installation Guide for Ringlock Scaffolding Brackets

>> Step 1: Inspect Components

>> Step 2: Position the Vertical Standards

>> Step 3: Attach the Bracket to the Standard

>> Step 4: Place Scaffold Boards on the Bracket

>> Step 5: Install Guardrails and Toe Boards

>> Step 6: Perform Safety Checks

● Maintenance and Inspection of Ringlock Scaffolding Brackets

● Advantages of Using Ringlock Scaffolding Brackets

● Case Study: Successful Use of Ringlock Scaffolding Brackets in High-Rise Construction

● Conclusion

● FAQ

>> 1. What is the difference between U-Type and O-Type ringlock scaffolding brackets?

>> 2. How do I determine the correct size of a ringlock scaffolding bracket?

>> 3. Are ringlock scaffolding brackets customizable?

>> 4. What materials are ringlock scaffolding brackets made from?

>> 5. Can ringlock scaffolding brackets be used for suspended scaffolding?

● Citations:

Choosing the right ringlock scaffolding bracket is crucial for ensuring safety, stability, and efficiency in any scaffolding project. This comprehensive guide will explore the types of brackets available, key considerations for selection, installation tips, maintenance advice, and answer frequently asked questions to help you make an informed decision. Whether you are a contractor, site engineer, or scaffolding supplier, understanding the nuances of ringlock scaffolding brackets will empower you to optimize your scaffolding system for maximum performance and safety.

Understanding Ringlock Scaffolding Brackets

Ringlock scaffolding is a modular system widely used in construction due to its versatility, quick assembly, and high load-bearing capacity. The brackets in a ringlock scaffolding system serve as extensions or supports for the working platforms, allowing for cantilevered decks or access platforms closer to structures. This makes them indispensable for complex scaffolding configurations where standard platforms cannot provide the necessary reach or support.

What Is a Ringlock Scaffolding Bracket?

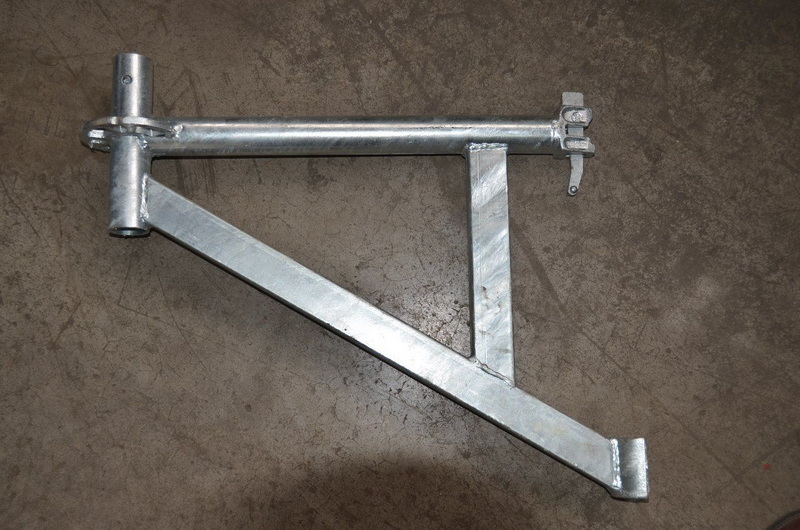

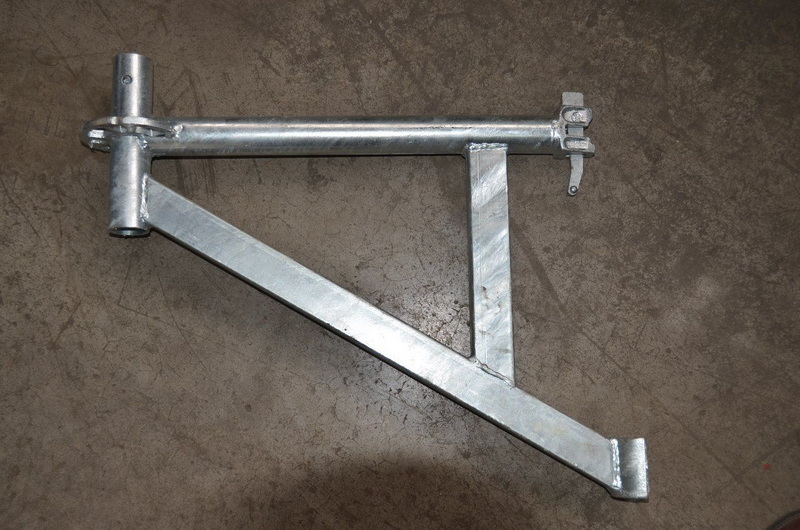

A ringlock scaffolding bracket is a structural component that attaches to vertical standards (uprights) and supports scaffold boards or decks horizontally. It enables the extension of working platforms beyond the main scaffold frame, providing additional space or access where needed. Brackets are engineered to bear significant loads safely and are designed to integrate seamlessly with other ringlock components.

Types of Ringlock Scaffolding Brackets

There are primarily two types of ringlock scaffolding brackets:

U-Type Console Brackets

- These are also called corner brackets. They feature U-shaped hooks that fit on the double-ribbed U profile of scaffold decks, eliminating hook compatibility issues between different deck types. Sizes are customized based on scaffold board widths, such as 320mm or 241mm. The U-type bracket is popular because it provides a secure, stable connection, and is easy to install.

O-Type Console Brackets

- These brackets have horizontal members made of OD48.3mm scaffold tubes and work with scaffold decks equipped with O plank hooks. Compatibility between different scaffold decks must be considered when using O-type brackets. O-type brackets are often preferred in projects requiring heavier load capacities or where scaffold decks with O hooks are already in use.

Board Bracket Options

Brackets come in configurations to hold one, two, or three scaffold boards, allowing flexibility in platform size. The number of boards supported affects the working area and load distribution.

| Bracket Type | Board Capacity | Typical Size (mm) | Weight (kg) |

| One Board U Bracket | 1 | 732 | 3.9 |

| Two Board U Bracket | 2 | 1092 | 6.4 |

| Three Board U Bracket | 3 | ~390 (varies) | 12 |

Custom sizes are also available to fit specific project requirements. For example, brackets can be manufactured for scaffold boards wider than 320mm or narrower than 241mm, depending on the working platform design.

Key Factors to Consider When Choosing a Ringlock Scaffolding Bracket

Selecting the right bracket involves understanding your project needs, scaffold design, and safety requirements. Here are the main factors to consider:

1. Compatibility with Scaffold Decks

Hook Type Matching:

- The bracket must match the hook type of the scaffold decks you are using. U-type brackets fit decks with U-profile hooks, while O-type brackets require decks with O hooks. Mixing incompatible brackets and decks can compromise stability.

Board Width:

- Measure the width of your scaffold boards or planks to ensure the bracket supports the correct number and size of boards. Using a bracket that is too narrow or too wide can cause unsafe working platforms.

2. Load Capacity and Safety

Working Load Requirements:

- Calculate the maximum anticipated load, including workers, tools, and materials. Choose brackets rated to safely carry this load with an appropriate safety margin.

Compliance with Standards:

- Ensure brackets comply with local and international safety standards such as OSHA (Occupational Safety and Health Administration), EN 12811 (European standard for scaffolding), or ISO certifications.

Structural Integrity:

- Inspect brackets for manufacturing defects, cracks, or deformations before use. Only use brackets certified by reputable manufacturers.

3. Material and Surface Treatment

Material Quality:

- Most ringlock scaffolding brackets are made from high-strength steel such as Q235 or equivalent grades. Steel provides excellent load-bearing capacity and durability.

Corrosion Resistance:

- Hot-dip galvanizing is the preferred surface treatment, providing a thick, uniform zinc coating that protects against rust and corrosion. This is especially important for outdoor or marine environments.

Alternative Coatings:

- Some brackets may be powder-coated or painted for specific aesthetic or environmental requirements, but galvanizing remains the best for long-term durability.

4. Project-Specific Requirements

Scaffolding Type:

- Different scaffolding configurations (masonry, suspended, outrigger, cantilever) may require specific bracket types or custom designs.

Environmental Conditions:

- For projects in harsh weather or corrosive environments, prioritize brackets with superior corrosion protection.

Platform Extension Needs:

- Determine how far the platform needs to extend from the main scaffold frame. Longer cantilevered brackets require higher load ratings and more robust construction.

5. Ease of Installation and Versatility

Modular Design:

- Brackets that integrate easily with ringlock standards, ledgers, and braces reduce assembly time and labor costs.

Adjustability:

- Some brackets offer adjustable lengths or configurations to accommodate varying platform widths or heights.

Compatibility with Accessories:

- Check if the bracket supports additional safety features such as guardrails, toe boards, or safety nets.

Detailed Installation Guide for Ringlock Scaffolding Brackets

Proper installation is vital to ensure the safety and effectiveness of your scaffolding system. Below are detailed steps and best practices for installing ringlock scaffolding brackets.

Step 1: Inspect Components

- Examine all brackets, scaffold boards, and standards for damage or defects.

- Verify that all components are clean and free of rust or debris.

Step 2: Position the Vertical Standards

- Set up vertical standards (uprights) at the required intervals according to your scaffold design.

- Use adjustable base jacks to level the scaffold on uneven ground.

Step 3: Attach the Bracket to the Standard

- Align the bracket's rosette or ringlock connection with the standard's rosette.

- Insert the wedge or locking pin securely to fix the bracket in place.

- Ensure the bracket is horizontal and firmly locked.

Step 4: Place Scaffold Boards on the Bracket

- Lay scaffold boards or decks on the bracket's horizontal support.

- Confirm that the boards fit snugly within the bracket's width and hook securely if applicable.

- Use clamps or safety pins if necessary to prevent board movement.

Step 5: Install Guardrails and Toe Boards

- Attach guardrails to the scaffold standards and brackets to protect workers from falls.

- Secure toe boards along the platform edges to prevent tools or materials from falling.

Step 6: Perform Safety Checks

- Double-check all connections for tightness and stability.

- Verify that the scaffold platform is level and free from hazards.

- Ensure load limits are not exceeded.

Maintenance and Inspection of Ringlock Scaffolding Brackets

Regular maintenance and inspection are essential to prolong the life of your brackets and maintain safety.

Routine Inspections:

- Conduct visual inspections before each use, checking for cracks, corrosion, or deformation.

Cleaning:

- Remove dirt, mud, or chemicals that may accelerate corrosion.

Repair or Replace:

- Immediately discard any damaged or worn brackets. Do not attempt to repair structural damage.

Storage:

- Store brackets in a dry, covered area to minimize exposure to moisture and corrosive elements.

Advantages of Using Ringlock Scaffolding Brackets

Flexibility:

- Easily extend platforms to accommodate complex building geometries.

Safety:

- Provide secure platforms with guardrails and toe boards, reducing fall risks.

Efficiency:

- Modular design reduces assembly time and labor costs.

Durability:

- High-quality materials and galvanizing ensure long service life.

Compatibility:

- Works seamlessly with ringlock scaffolding systems and accessories.

Case Study: Successful Use of Ringlock Scaffolding Brackets in High-Rise Construction

In a recent high-rise construction project in Shanghai, the contractor utilized custom-sized U-type ringlock scaffolding brackets to extend working platforms around complex building corners. The brackets supported two scaffold boards each, providing a safe and spacious working area for masons and painters. The hot-dip galvanized brackets withstood harsh weather conditions and reduced assembly time by 30%, demonstrating the practical benefits of selecting the right bracket.

Conclusion

Selecting the right ringlock scaffolding bracket is essential for creating safe, stable, and efficient scaffolding platforms. Understanding the types of brackets, ensuring compatibility with scaffold decks, considering load capacity, and choosing durable materials with proper surface treatment will help you optimize your scaffolding system. Always prioritize safety by adhering to installation guidelines and using certified components.

By investing time in choosing the correct bracket and maintaining it properly, you not only enhance worker safety but also improve project efficiency and reduce long-term costs. Whether you are working on a small renovation or a large-scale construction site, the right ringlock scaffolding bracket is a foundational element for success.

FAQ

1. What is the difference between U-Type and O-Type ringlock scaffolding brackets?

Answer: U-Type brackets have U-shaped hooks that fit double-ribbed U profile decks and avoid hook compatibility issues. O-Type brackets use horizontal scaffold tubes and require all scaffold decks to have compatible O plank hooks.

2. How do I determine the correct size of a ringlock scaffolding bracket?

Answer: The bracket size should match the width of your scaffold boards. For example, a two-board U bracket for 320mm wide decks is typically 1092mm center to center.

3. Are ringlock scaffolding brackets customizable?

Answer: Yes, many manufacturers offer custom sizes to fit specific project needs, including various lengths and board capacities.

4. What materials are ringlock scaffolding brackets made from?

Answer: They are usually made from high-strength steel such as Q235, with hot-dip galvanizing for corrosion resistance and durability.

5. Can ringlock scaffolding brackets be used for suspended scaffolding?

Answer: Yes, ringlock scaffolding brackets are versatile and can be used in suspended scaffolding, masonry scaffolding, outrigger scaffolding, and more.

Citations:

[1] https://www.wm-scaffold.com/ringlock-scaffold-u-bracket.html

[2] https://www.scaffoldssupply.com/Ringlock-Board-Brackets-s/153.htm

[3] https://www.wm-scaffold.com/ringlock-three-board-bracket/

[4] https://www.at-pac.com/ringlock/side-hop-up-bracket-o-type

[5] https://www.adtoscaffold.com/product/Ringlock_scaffolding_bracket.html

[6] https://apacsafety.com/ringlock-scaffolding-components-and-how-to-install-the-system/

[7] https://jumplyscaffolding.com/zh/ringlock-board-bracket-2/

[8] https://technocraftaustralia.com.au/ringlock-scaffolding/

[9] https://www.ekscaffolding.com/ringlock-scaffolding.html

[10] https://tswufang.en.made-in-china.com/product/FwgfRqbrrWUd/China-Ringlock-Scaffolding-Triangle-Bracket-Cantilever-Side-Bracket.html

[11] https://www.wm-scaffold.com/ring-lock-scaffold.html

[12] https://www.youtube.com/watch?v=JsZkR5P7IAQ