Content Menu

● What Is a 20 Foot Aluminum Walk Plank?

● Why Choose a 20 Foot Aluminum Walk Plank for Roofing and Scaffolding?

>> Lightweight and Easy Handling

>> High Strength and Safety

>> Corrosion and Weather Resistance

>> Versatility in Applications

● Technical Specifications of 20 Foot Aluminum Walk Planks

● Practical Uses in Roofing and Scaffolding

>> Roofing Platforms

>> Scaffold Walkways

>> Ladder Jack Scaffolds

>> Suspended Scaffolds and Swing Stages

● Advantages Over Other Materials

● Safety Considerations

● Maintenance Tips

● Additional Benefits of Using 20 Foot Aluminum Walk Planks

>> Enhanced Worker Productivity

>> Environmental Friendliness

>> Longevity and Cost Efficiency

● Conclusion

● FAQ

>> 1. What is the load capacity of a 20 foot aluminum walk plank?

>> 2. Can a 20 foot aluminum walk plank be used on sloped roofs?

>> 3. How wide are typical 20 foot aluminum walk planks?

>> 4. Are 20 foot aluminum walk planks slip-resistant?

>> 5. How should I maintain my aluminum walk plank?

When it comes to roofing and scaffolding projects, selecting the right plank is critical for safety, efficiency, and durability. The 20 foot aluminum walk plank is a popular choice among professionals due to its lightweight nature, high strength, and corrosion resistance. But is it truly ideal for roofing and scaffolding applications? This comprehensive article explores the features, benefits, and practical considerations of using a 20 foot aluminum walk plank.

What Is a 20 Foot Aluminum Walk Plank?

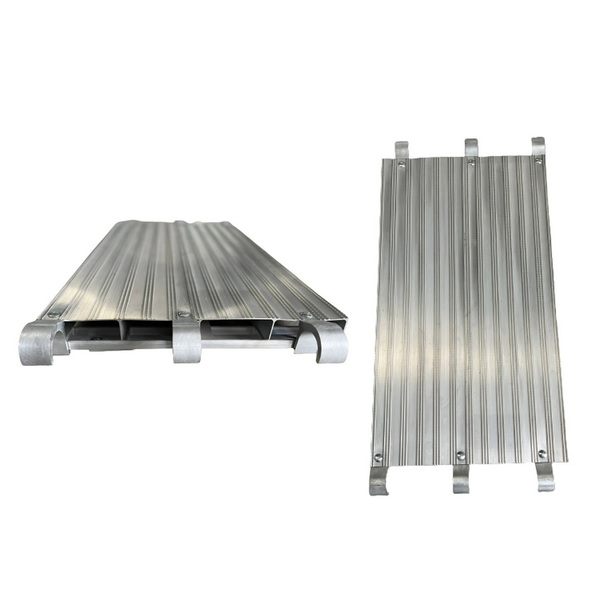

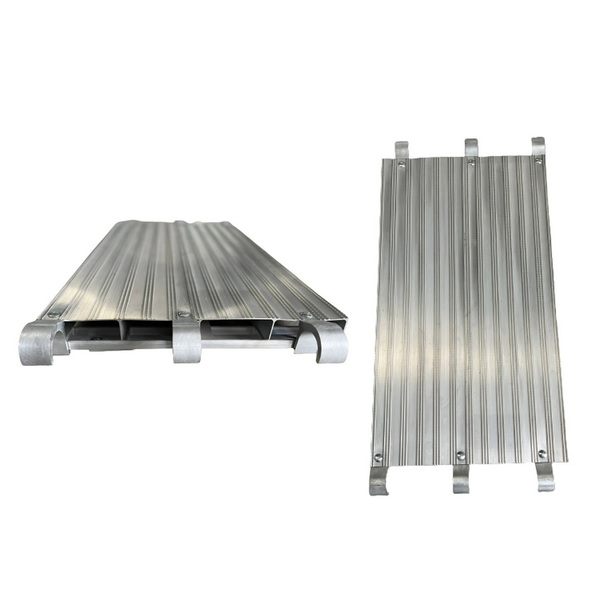

A 20 foot aluminum walk plank is a long, narrow platform typically measuring 20 feet in length and approximately 12 to 20 inches in width, constructed from high-grade aluminum alloy. It is designed to serve as a safe, stable walking and working surface on scaffolds, ladder jacks, swing stages, and other elevated platforms.

Common features include:

- Lightweight Construction: Aluminum's low density makes the plank easy to transport and install.

- High Load Capacity: Most 20 foot aluminum planks support up to 500 lbs, suitable for two workers plus tools.

- Slip-Resistant Surface: Textured or coated decking enhances safety.

- Corrosion Resistance: Aluminum withstands weather and moisture without rusting.

- Ergonomic Handles: Molded handles for easy carrying and positioning.

Why Choose a 20 Foot Aluminum Walk Plank for Roofing and Scaffolding?

Lightweight and Easy Handling

Roofing and scaffolding jobs often require frequent repositioning of platforms. The lightweight nature of aluminum planks reduces worker fatigue and speeds up assembly and dismantling.

High Strength and Safety

Despite being lightweight, these planks offer strong support for workers and equipment. A 20 foot aluminum plank typically supports a 500-pound load, meeting OSHA and ANSI safety standards.

Corrosion and Weather Resistance

Roofing projects expose equipment to rain, snow, and other elements. Aluminum planks resist corrosion, maintaining structural integrity and safety over time.

Versatility in Applications

These planks are compatible with various scaffolding systems, ladder jacks, and suspended platforms, making them adaptable to diverse roofing and maintenance scenarios.

Technical Specifications of 20 Foot Aluminum Walk Planks

| Feature | Specification |

| Length | 20 feet (240 inches) |

| Width | 12 to 20 inches |

| Load Capacity | 500 lbs (approx. 227 kg) |

| Weight | Approximately 90-105 lbs |

| Material | High-grade aluminum alloy |

| Surface | Slip-resistant textured or coated |

| Compliance | OSHA, ANSI certified |

Practical Uses in Roofing and Scaffolding

Roofing Platforms

- Provide stable walking surfaces across roof edges.

- Support workers carrying tools and materials.

- Lightweight design allows easy repositioning on sloped roofs.

Scaffold Walkways

- Connect scaffold bays for safe passage.

- Support workers moving between scaffold sections.

- Compatible with various scaffold frame widths.

Ladder Jack Scaffolds

- Span between ladders to create temporary work platforms.

- Lightweight for quick setup and adjustment.

Suspended Scaffolds and Swing Stages

- Used as decking on suspended platforms for exterior facade work.

- Durable and safe for high-elevation tasks.

Advantages Over Other Materials

| Material | Weight | Durability | Maintenance | Cost |

| Aluminum Plank | Lightweight (90-105 lbs) | Corrosion resistant | Low | Moderate |

| Wood Plank | Heavier | Prone to rot | High | Low |

| Steel Plank | Heaviest | Strong but rusts | Requires coating | Higher |

Safety Considerations

- Always adhere to load ratings; do not exceed 500 lbs per plank.

- Ensure planks are properly supported at recommended intervals (usually 6 feet max).

- Use guardrails and toe boards when working at height.

- Inspect planks regularly for dents, cracks, or surface wear.

- Store planks in dry, sheltered areas to prolong lifespan.

Maintenance Tips

- Clean planks regularly to remove debris and contaminants.

- Check for any signs of corrosion or structural damage.

- Replace damaged planks immediately.

- Lubricate any moving parts if applicable.

- Follow manufacturer's guidelines for storage and care.

Additional Benefits of Using 20 Foot Aluminum Walk Planks

Enhanced Worker Productivity

Due to their lightweight nature, aluminum planks allow workers to reposition platforms quickly, reducing downtime and increasing productivity on the job site.

Environmental Friendliness

Aluminum is a recyclable material. Using aluminum planks contributes to sustainable building practices by reducing the environmental impact compared to non-recyclable materials.

Longevity and Cost Efficiency

Though aluminum planks may have a higher initial cost compared to wood, their durability and low maintenance needs often result in long-term cost savings.

Conclusion

A 20 foot aluminum walk plank is an excellent choice for roofing and scaffolding due to its combination of lightweight design, high strength, corrosion resistance, and safety features. It supports up to 500 lbs, making it suitable for two workers and their tools. Its versatility across different scaffold systems and ease of handling make it ideal for dynamic construction environments. Proper use, regular inspection, and maintenance ensure these planks provide safe and reliable platforms for elevated work.

FAQ

1. What is the load capacity of a 20 foot aluminum walk plank?

Most 20 foot aluminum walk planks support up to 500 lbs, suitable for two workers and their equipment.

2. Can a 20 foot aluminum walk plank be used on sloped roofs?

Yes, its lightweight and sturdy design make it suitable for roofing applications, including sloped surfaces.

3. How wide are typical 20 foot aluminum walk planks?

Widths commonly range from 12 to 20 inches, depending on the manufacturer and application.

4. Are 20 foot aluminum walk planks slip-resistant?

Yes, most feature textured or coated surfaces to enhance traction and reduce slip hazards.

5. How should I maintain my aluminum walk plank?

Regular cleaning, inspection for damage, and proper storage in dry conditions are essential for longevity and safety.