Content Menu

● Understanding Scaffolding Accessories

● The Korean Scaffolding Accessories Market Landscape

● Leading Scaffolding Accessories Manufacturers and Suppliers in Korea

>> 1. Dong Myung Industrial Co., Ltd.

>> 2. Steel Korea Co., Ltd.

>> 3. Seobo Industrial Co., Ltd.

>> 4. Hory Korea Co., Ltd.

>> 5. KS Form

>> 6. Viser System Co., Ltd.

● OEM Capabilities and Export Services

● Innovation and Market Trends

● Applications of Korean Scaffolding Accessories

● Conclusion

● FAQ

>> 1. What types of certifications do Korean scaffolding accessories manufacturers typically hold?

>> 2. Can Korean manufacturers provide custom scaffolding accessories based on unique project specifications?

>> 3. What are the common export markets for Korean scaffolding accessories?

>> 4. How do Korean manufacturers ensure the durability and safety of their scaffolding accessories?

>> 5. What innovations are being seen in the Korean scaffolding accessories market?

South Korea's construction sector is characterized by rapid development, technological integration, and a strong emphasis on efficiency and safety. The demand for high-quality scaffolding accessories is consistently high, driven by numerous infrastructure projects, commercial developments, and residential constructions. This article provides an in-depth look into the leading scaffolding accessories manufacturers and suppliers in Korea, detailing their product offerings, manufacturing capabilities, and their role in the global market. For foreign brands, wholesalers, and producers seeking reliable OEM partners, understanding the Korean market is crucial.

Understanding Scaffolding Accessories

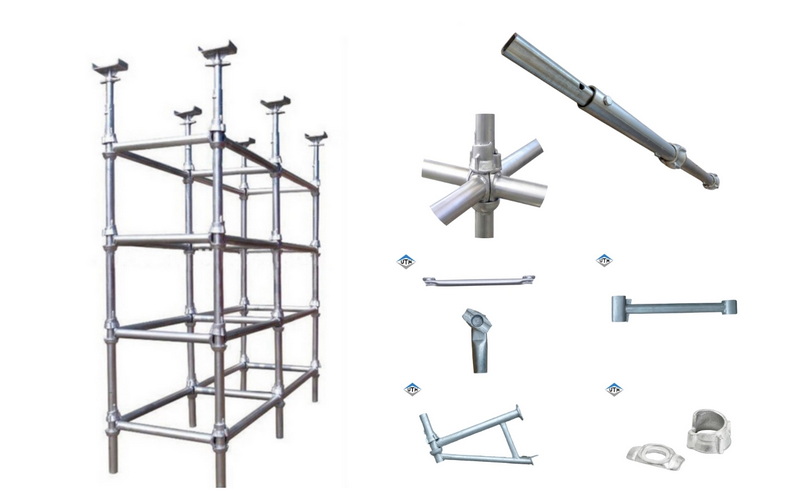

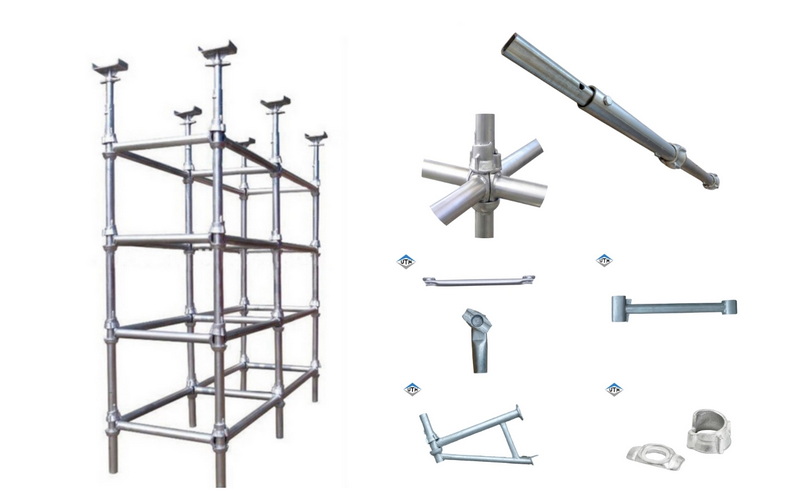

Scaffolding accessories are critical components that ensure the structural integrity, safety, and functionality of scaffolding systems. These components facilitate assembly, provide stability, and enhance worker safety. Key accessories include:

- Steel Pipe Props: Used for vertical support in formwork and slab construction.

- Steel Planks: Provide safe working platforms for workers and materials.

- Scaffold Pipes: Fundamental structural elements of various scaffolding types.

- Scaffold Couplers/Clamps: Essential for connecting pipes and ensuring stability. These include pressed clamps and drop forged clamps for different connection requirements.

- Jack Bases: Adjustable components that provide a level and stable foundation for scaffolding on uneven ground.

- Ringlock Ledgers: Horizontal components in ringlock scaffolding systems, crucial for creating working levels.

- Scaffolding Mainframes: Core structural frames for frame scaffolding systems.

- System Scaffolding Components: Specialized parts for modular systems like ringlock and kwikstage scaffolding.

- Scaffolding Stairs: Provide safe and easy access between different levels of a scaffold.

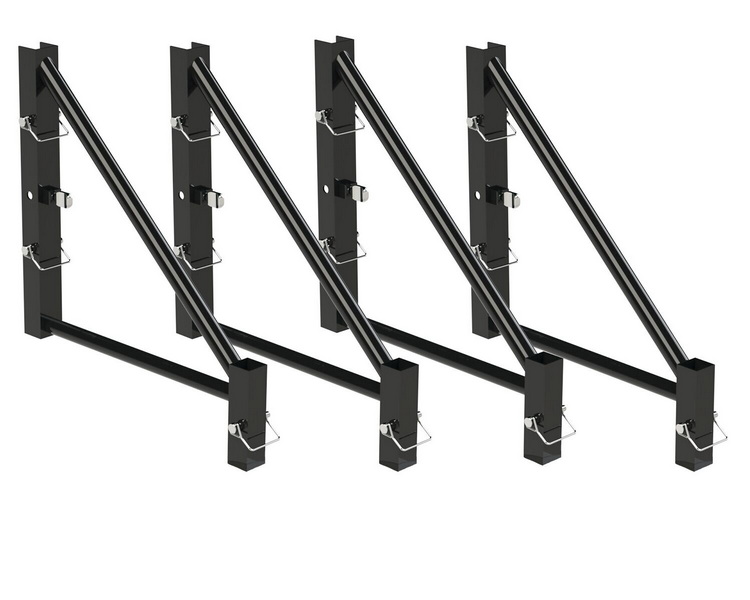

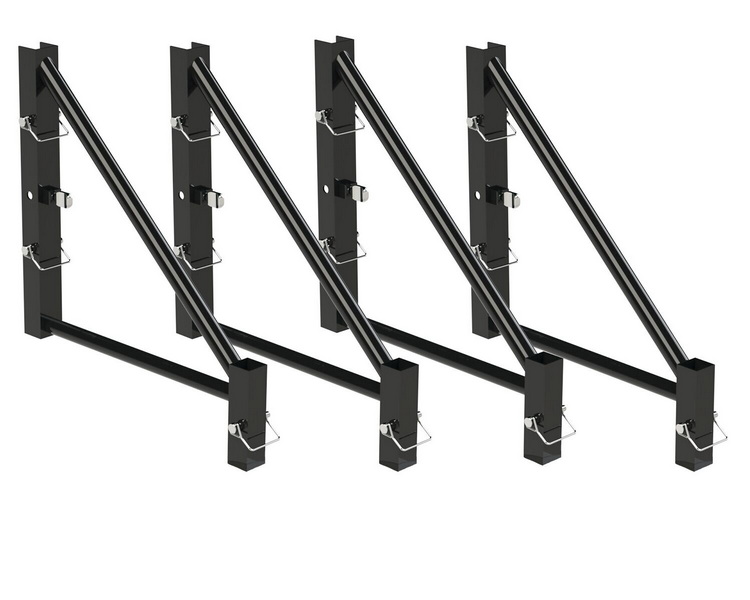

- Brackets: Used to extend the working platform or provide support for various components.

- Wall Anchors: Secure the scaffolding to the building structure for added stability.

These accessories comply with Korean and international safety standards, ensuring reliability on construction sites.

The Korean Scaffolding Accessories Market Landscape

The South Korean scaffolding accessories market is dynamic, marked by:

- Technological Advancement: Korean manufacturers often integrate advanced production techniques, including automated welding and precision engineering.

- Quality and Durability: Products are generally known for their robust construction and long lifespan, designed to withstand challenging construction environments.

- Export Orientation: Many Korean scaffolding accessories manufacturers and suppliers actively export their products globally, particularly to Southeast Asia and the Middle East.

- OEM Services: A significant number of companies offer OEM services, providing custom solutions, branding, and packaging for international clients.

- Certifications: Adherence to international quality management standards like ISO 9001 and environmental management standards like ISO 14001 is common among reputable scaffolding accessories suppliers.

The Korean market is also influenced by the country's focus on sustainability and safety, encouraging manufacturers to innovate in eco-friendly materials and ergonomic designs.

Leading Scaffolding Accessories Manufacturers and Suppliers in Korea

Several key players dominate the Korean market for scaffolding accessories. These companies offer a wide range of products and often provide export and OEM services.

1. Dong Myung Industrial Co., Ltd.

- Overview: Established in 1992, Dong Myung Industrial Co., Ltd. is a local Korean scaffolding manufacturer with over 100 employees and approximately 70 experienced engineers.

- Key Products: Their product range includes steel pipe props, steel planks, scaffolding mainframes, and scaffold couplers. They are also noted as a leading manufacturer of aluminum planks.

- Strengths: Known for providing high-quality products and offering export services primarily to Southeast Asia and the Middle East.

- Location: Seoul, South Korea.

Dong Myung Industrial emphasizes research and development, continuously improving product designs to meet evolving safety standards and customer needs.

2. Steel Korea Co., Ltd.

- Overview: Steel Korea Co., Ltd. is a prominent scaffolding supplier based in Hwasung-city.

- Key Products: They offer a comprehensive range of scaffolding products, including scaffold props, scaffolding pipes, steel planks, and mould forms. They are also a significant supplier of aluminum planks.

- Strengths: Provides export services worldwide and ensures product certifications are readily available on their official website. Their products are recognized for excellent quality.

- Location: Hwasung-city, Gyeonggi-do.

Steel Korea invests heavily in quality control and uses advanced galvanizing techniques to enhance corrosion resistance, extending the lifespan of their scaffolding accessories.

3. Seobo Industrial Co., Ltd.

- Overview: Established in 1998, Seobo Industrial Co., Ltd. is a highly reputable company with an export award of 5 million dollars.

- Key Products: Their offerings include bridge formwork, scaffold props, scaffolding accessories, and assembling simulation. They are also listed among leading suppliers of aluminum planks.

- Strengths: Holds ISO 14001 and ISO 9001 certifications, emphasizing both quality and environmental management. They have an established sales office in Seoul and a branch in New Delhi, India.

- Location: Eumseong-gun, Chungcheongbuk-do.

Seobo Industrial is known for its commitment to environmental sustainability and actively promotes green manufacturing practices.

4. Hory Korea Co., Ltd.

- Overview: Founded in 2000, Hory Korea Co., Ltd. is a national-class scaffolding materials manufacturer with its main office and factory in Gimhae and stock in Gyeonggi province. They were established with significant investment from SRG (Super Rental Group), a Japanese company.

- Key Products: They provide a wide array of scaffolding materials, including steel pipes, ringlock scaffolding, Euro forms, scaffolding ledgers, clamps, jack bases, joints, brackets, stairs, system supports, working towers, and wall anchors.

- Strengths: Exports extensively to Japan for over fifteen years, and more recently to Singapore, Mongolia, and Malaysia. They also export used scaffolding materials from construction sites in Japan to countries like Mongolia, Vietnam, Singapore, and Iran.

- Location: Gimhae-si, Gyeongsangnam-do.

Hory Korea's long-standing partnership with Japanese firms has helped it adopt high standards of quality and customer service.

5. KS Form

- Overview: KS Form specializes in scaffolding and formwork, with a commitment to 100% domestic manufacturing of all materials except some timber beams.

- Key Products: Their products include scaffold standards, jack bases, and ringlock ledgers.

- Strengths: Focuses on supporting domestic construction projects and offers cost savings on shipping for local clients.

- Location: Seoul, South Korea.

KS Form is recognized for its quick turnaround times and flexibility in meeting customer demands.

6. Viser System Co., Ltd.

- Overview: Established in 2004, Viser System Co., Ltd. has two locations in Korea and a cooperative formwork factory. They have formed partnerships with major companies like Samsung Heavy Industries (2017) and signed an OEM contract with a Japanese temporary equipment manufacturer (2015).

- Key Products: They supply ringlock scaffolding, jack bases, and scaffold pipes.

- Strengths: Strong focus on OEM partnerships and collaboration with both domestic and international companies.

- Location: Gimhae-si, Gyeongsangnam-do.

Viser System is known for its innovative approach to product design and its ability to customize solutions for clients.

Other notable scaffolding accessories suppliers in South Korea include Hyundai Metal Co. Ltd., Techstar Co., Ltd., HANDYSOFT, Inc., JM Global Co., Ltd., MYUNGJIN INDUSTRIAL CO.,LTD, and Sungjistill. Major industrial players like Hyundai Mipo Dockyard Co Ltd and HD Hyundai Mipo Co Ltd are also listed as manufacturers and suppliers of scaffolding accessories.

OEM Capabilities and Export Services

Korean scaffolding accessories manufacturers and suppliers are well-equipped to handle OEM services for international brands, wholesalers, and producers. Their capabilities typically include:

- Customization: Producing scaffolding accessories according to specific design requirements, dimensions, and material specifications.

- Branding and Packaging: Offering private labeling and custom packaging to align with client brand identities.

- Quality Assurance: Implementing rigorous quality control processes to ensure products meet international standards and client expectations. Many factories have advanced testing equipment for load-bearing capacity, material strength, and corrosion resistance.

- Logistics and Export Expertise: Extensive experience in international shipping, including documentation, customs clearance, and efficient delivery to various global destinations. This is supported by their established export routes to regions like Southeast Asia, the Middle East, and Japan.

- Technical Support: Providing technical guidance and support for product integration and usage.

This robust OEM framework makes South Korea an attractive sourcing destination for high-quality, customized scaffolding accessories.

Innovation and Market Trends

The Korean scaffolding accessories market is continuously evolving with key trends:

- Automation in Manufacturing: Increased adoption of robotics and automated systems in production lines to enhance efficiency, precision, and consistency in the manufacturing of scaffolding accessories.

- Sustainable Practices: Growing emphasis on environmentally friendly materials and production processes, including the use of recycled steel and energy-efficient operations.

- Digitalization: Integration of digital technologies for design, simulation, and project management. This includes Building Information Modeling (BIM) to optimize scaffolding design and minimize material waste.

- Lightweight Materials: Continued development and use of lightweight materials like aluminum for scaffolding planks and other accessories to improve portability and ease of assembly without compromising strength.

- Safety Enhancements: Innovations in safety features such as improved locking mechanisms, anti-slip surfaces for planks, and ergonomic designs for easier handling of scaffolding accessories.

These trends reflect Korea's commitment to advancing construction safety and efficiency through cutting-edge manufacturing practices.

Applications of Korean Scaffolding Accessories

Korean-manufactured scaffolding accessories are utilized across a wide spectrum of construction and industrial applications:

- High-Rise Buildings: Providing stable and safe access for facade work, window installation, and structural construction.

- Infrastructure Projects: Essential for bridge construction, tunnel lining, and major civil engineering works requiring robust support systems.

- Shipbuilding and Offshore Platforms: Specialized corrosion-resistant scaffolding accessories are crucial for maintenance and construction in marine environments.

- Industrial Facilities: Supporting maintenance, repair, and new construction in factories, power plants, and chemical facilities.

- Residential and Commercial Developments: Used in both new builds and renovation projects, ensuring safe working environments.

The versatility and quality of Korean scaffolding accessories make them suitable for diverse and demanding environments.

Conclusion

South Korea has established itself as a significant hub for high-quality scaffolding accessories manufacturers and suppliers. With a strong emphasis on advanced manufacturing, stringent quality control, and robust OEM capabilities, Korean companies are well-positioned to meet the demands of global construction projects. For international brands, wholesalers, and producers, partnering with Korean scaffolding accessories manufacturers offers access to reliable, durable, and competitively priced products, backed by extensive export experience and technical support. The continuous innovation in materials and manufacturing processes ensures that Korean scaffolding accessories remain at the forefront of safety and efficiency in the global construction industry.

FAQ

1. What types of certifications do Korean scaffolding accessories manufacturers typically hold?

Korean scaffolding accessories manufacturers often hold international certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. Many products also comply with Korean Industrial Standards (KS) and other relevant international safety standards.

2. Can Korean manufacturers provide custom scaffolding accessories based on unique project specifications?

Yes, many Korean scaffolding accessories manufacturers and suppliers offer comprehensive OEM services, allowing for customization based on specific design requirements, material preferences, and branding needs. This includes variations in size, load capacity, and surface finishes.

3. What are the common export markets for Korean scaffolding accessories?

Korean scaffolding accessories are widely exported, with significant markets in Southeast Asia, the Middle East, and Japan. Some manufacturers also export to other regions globally, including used scaffolding materials.

4. How do Korean manufacturers ensure the durability and safety of their scaffolding accessories?

Korean manufacturers ensure durability and safety through strict quality control processes, advanced manufacturing techniques like automated welding, and the use of high-strength materials such as galvanized steel and aluminum. Products are designed to meet or exceed relevant safety standards.

5. What innovations are being seen in the Korean scaffolding accessories market?

Innovations in the Korean scaffolding accessories market include increased automation in manufacturing, the development of lightweight materials (e.g., aluminum planks), enhanced safety features, and the integration of digital tools like BIM for optimized design and project management.