Content Menu

● Understanding Ladder Clamps

● Key Benefits of Using Ladder Clamps in Scaffolding Systems

>> Enhanced Safety

>> Improved Stability

>> Increased Efficiency

>> Compliance with Safety Regulations

>> Versatility and Adaptability

>> Reduced Risk of Equipment Damage

● Types of Ladder Clamps

● Best Practices for Using Ladder Clamps

>> Proper Installation

>> Regular Inspection

>> Load Capacity

>> Proper Ladder Placement

>> Training and Supervision

● Common Mistakes to Avoid

● Conclusion

● FAQ

>> 1. What is the primary purpose of using ladder clamps in scaffolding?

>> 2. What types of ladders are compatible with ladder clamps?

>> 3. How often should ladder clamps be inspected?

>> 4. Are there specific safety regulations regarding the use of ladder clamps?

>> 5. Can I use any type of clamp to secure a ladder to scaffolding?

● Citations:

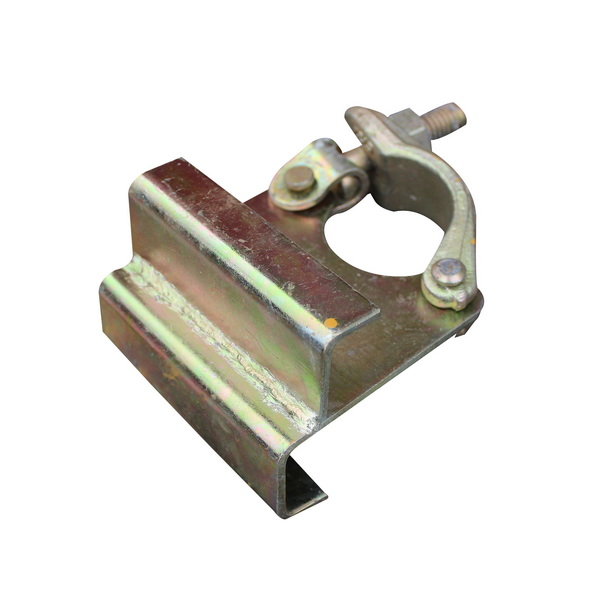

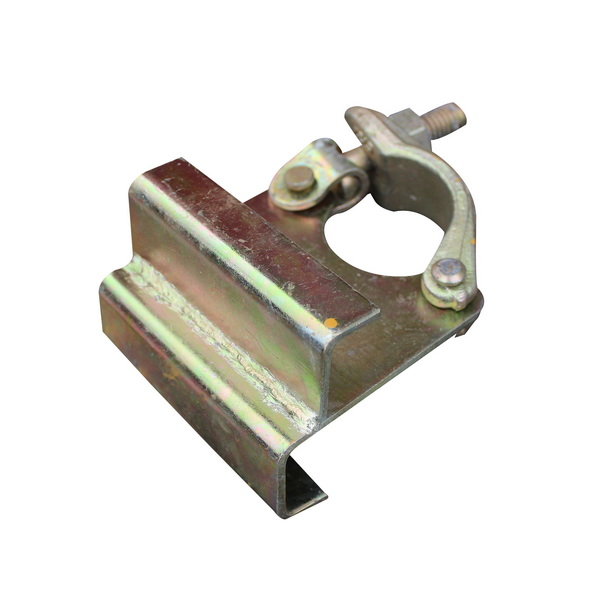

Ladder clamps are crucial components in scaffolding systems, offering numerous benefits related to safety, stability, and efficiency. These devices are specifically designed to securely attach ladders to scaffolding structures, providing workers with safe and reliable access to elevated work areas. This article explores the key advantages of using ladder clamps in scaffolding systems, ensuring that your setup meets safety standards and promotes a productive work environment. Proper utilization of "scaffolding ladder clamp" enhances worker safety and accessibility.

Understanding Ladder Clamps

Ladder clamps are specialized fasteners used to connect ladders to scaffolding frames. They typically consist of a clamping mechanism that securely grips both the ladder stiles and the scaffolding tubes, preventing movement and slippage. These clamps are designed to be easy to install and adjust, allowing workers to quickly and safely attach ladders to the scaffolding structure. The primary goal of a "scaffolding ladder clamp" is to provide a stable and secure access point, reducing the risk of falls and injuries.

Key Benefits of Using Ladder Clamps in Scaffolding Systems

Enhanced Safety

One of the most significant benefits of using ladder clamps is enhanced safety. By securely attaching ladders to the scaffolding, these clamps prevent the ladder from slipping, sliding, or tipping over. This provides workers with a stable and secure climbing surface, reducing the risk of falls and injuries. Ladder clamps are particularly important in situations where the scaffolding is exposed to wind, vibration, or other environmental factors that could destabilize the ladder. Improving safety is a core benefit of the "scaffolding ladder clamp," reducing jobsite accidents.

Improved Stability

Ladder clamps significantly improve the stability of the entire scaffolding system. When a ladder is securely attached to the scaffolding frame, it becomes an integral part of the structure, adding to its overall rigidity and strength. This is particularly important for tall or complex scaffolding setups, where stability is critical for preventing collapses and ensuring worker safety. Enhanced stability through the "scaffolding ladder clamp" contributes to a more secure work platform.

Increased Efficiency

Using ladder clamps can also increase efficiency on the job site. By providing a safe and reliable access point, these clamps allow workers to quickly and easily move between different levels of the scaffolding. This reduces the time spent setting up and adjusting ladders, allowing workers to focus on their tasks. Additionally, the secure attachment provided by ladder clamps minimizes the need for constant monitoring and adjustments, freeing up workers to perform other duties. Streamlining access with a "scaffolding ladder clamp" boosts productivity on scaffolding projects.

Compliance with Safety Regulations

Many safety regulations and standards require the use of ladder clamps or similar devices to secure ladders to scaffolding structures. By using ladder clamps, you can ensure that your scaffolding setup complies with these regulations, avoiding potential fines and penalties. Compliance with safety standards is essential for maintaining a safe and legal work environment. The "scaffolding ladder clamp" helps ensure adherence to scaffolding safety guidelines and regulations.

Versatility and Adaptability

Ladder clamps are versatile and adaptable to various scaffolding configurations. They can be used with different types of ladders and scaffolding systems, making them a valuable addition to any construction site. Some ladder clamps are adjustable, allowing them to accommodate different ladder widths and scaffolding tube diameters. This versatility makes ladder clamps a cost-effective solution for securing ladders to scaffolding in a wide range of applications. Adaptability makes the "scaffolding ladder clamp" a flexible solution for diverse job site needs.

Reduced Risk of Equipment Damage

When ladders are not properly secured to scaffolding, they can rub against the scaffolding tubes, causing damage to both the ladder and the scaffolding. Ladder clamps prevent this by providing a secure and stable connection, minimizing the risk of equipment damage. This can save money on repairs and replacements, as well as extend the lifespan of your ladders and scaffolding. Protecting equipment is an added benefit of the "scaffolding ladder clamp," reducing wear and tear.

Types of Ladder Clamps

1. Fixed Ladder Clamps: These clamps are designed for specific ladder and scaffolding tube sizes, providing a secure and permanent connection.

2. Adjustable Ladder Clamps: These clamps can be adjusted to accommodate different ladder widths and scaffolding tube diameters, offering greater versatility.

3. Locking Ladder Clamps: These clamps feature a locking mechanism to prevent accidental disengagement, enhancing safety.

4. Universal Ladder Clamps: These clamps are designed to fit a wide range of ladder and scaffolding systems, providing a universal solution for securing ladders to scaffolding.

The correct type of "scaffolding ladder clamp" is key for safe and effective ladder integration within the scaffold structure.

Best Practices for Using Ladder Clamps

Proper Installation

Ensure that ladder clamps are properly installed according to the manufacturer's instructions. Check that the clamps are securely fastened to both the ladder stiles and the scaffolding tubes. Avoid over-tightening the clamps, as this can damage the ladder or the scaffolding.

Regular Inspection

Inspect ladder clamps regularly for signs of wear, damage, or corrosion. Check that the clamps are still securely fastened and that the locking mechanisms (if any) are functioning properly. Replace any damaged or worn clamps immediately.

Load Capacity

Never exceed the load capacity of the ladder or the ladder clamps. Ensure that the ladder is only used by one person at a time, and that no heavy materials or equipment are carried up or down the ladder.

Proper Ladder Placement

Place the ladder at the correct angle, with the base of the ladder positioned a safe distance from the scaffolding. Ensure that the ladder extends at least 3 feet above the top of the scaffolding to provide a handhold.

Training and Supervision

Provide workers with proper training on the safe use of ladders and ladder clamps. Supervise workers to ensure that they are following safety guidelines and using the equipment correctly.

Following these best practices maximizes the safety benefits of using a "scaffolding ladder clamp."

Common Mistakes to Avoid

- Using Damaged Clamps: Never use ladder clamps that are cracked, bent, or otherwise damaged.

- Over-Tightening Clamps: Over-tightening can damage the clamp and the scaffolding.

- Ignoring Load Capacity: Exceeding the load capacity can lead to clamp failure and accidents.

- Improper Installation: Incorrectly installed clamps can reduce their effectiveness and increase the risk of accidents.

- Neglecting Inspections: Failing to inspect clamps regularly can result in undetected damage or wear.

Avoiding these mistakes is crucial for maintaining a safe and stable scaffolding system. Correct usage of "scaffolding ladder clamp" is vital for hazard prevention.

Conclusion

Ladder clamps offer numerous benefits in scaffolding systems, including enhanced safety, improved stability, increased efficiency, compliance with safety regulations, versatility, and reduced risk of equipment damage. By using ladder clamps correctly and following best practices, you can create a safer and more productive work environment for your construction projects. The right "scaffolding ladder clamp" is a key component for a secure and efficient scaffolding setup.

FAQ

1. What is the primary purpose of using ladder clamps in scaffolding?

The primary purpose is to enhance safety by securely attaching ladders to scaffolding, preventing slips and falls.

2. What types of ladders are compatible with ladder clamps?

Ladder clamps are versatile and can be used with various types of ladders, including aluminum, fiberglass, and wooden ladders. Adjustable clamps offer the most flexibility.

3. How often should ladder clamps be inspected?

Ladder clamps should be inspected regularly, ideally before each use, to ensure they are in good condition and properly functioning.

4. Are there specific safety regulations regarding the use of ladder clamps?

Yes, many safety regulations and standards require the use of ladder clamps or similar devices to secure ladders to scaffolding structures.

5. Can I use any type of clamp to secure a ladder to scaffolding?

No, it is essential to use ladder clamps specifically designed for this purpose. Other types of clamps may not provide the necessary security and stability.

Citations:

[1] https://www.tp-scaffold.com/how-do-i-choose-the-right-girder-clamp-for-my-scaffolding-setup.html

[2] https://brandsafway.com/uploads/files/orn401_bsl_tube_and_clamp_product_brochure.pdf

[3] https://www.altradgeneration.com/assets/files/guides_and_documents/scaffolding/scaffold-coupler-manual.pdf

[4] https://www.acrow.com.au/wp-content/uploads/2020/11/couplers-product-guide.pdf

[5] https://www.tp-scaffold.com/how-to-choose-the-best-scaffolding-beam-clamp-for-your-project.html

[6] https://rlsdhamal.com/scaffolding-couplers-working-load-capacity/

[7] https://www.labour.gov.hk/eng/public/os/B/mss.pdf

[8] https://firstfence.co.uk/girder-clamps

[9] https://www.gd-scaffold.com/news/understanding-the-load-capacity-of-scaffolding-clamps.html

[10] https://www.londonscaffoldingsupplies.co.uk/scaffold-gravlock-girder-beam-clamps/

[11] https://www.alibaba.com/showroom/scaffolding-beam-clamp-capacity.html