Content Menu

● Introduction to the 12 Foot Aluminum Plank

● Key Features of 12 Foot Aluminum Planks

● Best Uses for a 12 Foot Aluminum Plank

>> 1. Scaffold Platforms

>> 2. Ladder Jack Scaffolding

>> 3. Swing Stages and Suspended Scaffolding

>> 4. Catwalks and Temporary Walkways

>> 5. Event Staging and Platforms

● Advantages Over Other Materials

● Factors to Consider When Using a 12 Foot Aluminum Plank

>> Load Capacity

>> Support Spacing

>> Environmental Conditions

>> Proper Installation

● Maintenance and Safety Tips

● Extended Uses and Innovative Applications

● Conclusion

● FAQ

>> 1. What is the typical load capacity of a 12 foot aluminum plank?

>> 2. Can a 12 foot aluminum plank be used on ladder jack scaffolding?

>> 3. Are 12 foot aluminum planks slip-resistant?

>> 4. How should 12 foot aluminum planks be maintained?

>> 5. Can 12 foot aluminum planks be used outdoors?

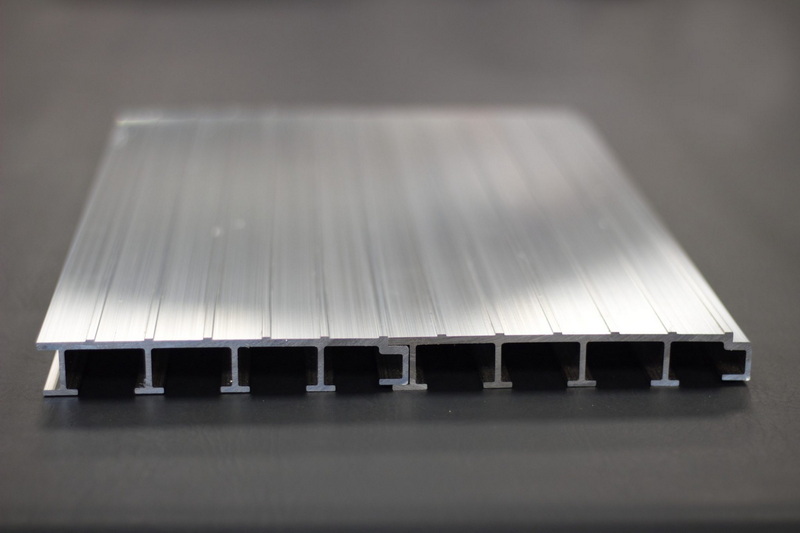

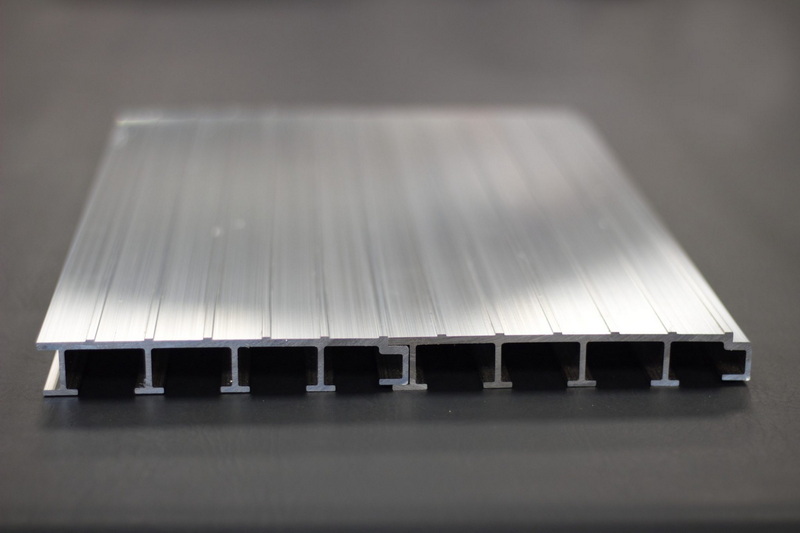

The 12 foot aluminum plank is a versatile and widely used tool across various industries, especially in construction, maintenance, and event staging. Known for its lightweight yet durable design, it offers a safe and reliable working platform.

Introduction to the 12 Foot Aluminum Plank

A 12 foot aluminum plank is typically a scaffold plank or stage platform made from high-quality aluminum alloy, measuring 12 feet in length and approximately 12 to 14 inches in width. Its design maximizes strength while minimizing weight, making it easy to handle and install.

The plank is commonly used as a working platform on scaffolds, ladder jacks, swing stages, catwalks, and other elevated work areas.

Key Features of 12 Foot Aluminum Planks

- Lightweight: Aluminum's low density makes the plank easy to transport and maneuver.

- High Strength: Despite its light weight, it supports up to 500 lbs, suitable for two workers plus tools.

- Corrosion Resistance: Galvanized or coated aluminum resists rust and weather damage.

- Slip-Resistant Surface: Many planks feature textured or coated surfaces to prevent slips.

- Versatile Length: 12 feet is a practical length for many scaffold setups and can span common bay widths.

- Easy to Cut and Modify: Aluminum planks can be cut with standard wood saws, facilitating custom fits.

Best Uses for a 12 Foot Aluminum Plank

1. Scaffold Platforms

The most common use is as a platform on frame scaffolds, ringlock scaffolds, or system scaffolds. The 12 foot length fits well between scaffold frames spaced typically 6 feet apart, providing a stable working surface.

- Supports workers performing masonry, painting, plastering, or installation tasks.

- Compatible with ladder jack scaffolds and swing stages.

2. Ladder Jack Scaffolding

12 foot aluminum planks are ideal for ladder jack scaffolds, where two ladders support the plank at each end.

- Provides a safe and sturdy platform for painting, drywall work, or electrical installations.

- Lightweight nature makes setup and repositioning easier.

3. Swing Stages and Suspended Scaffolding

Used as decking on suspended scaffolds for facade work, window cleaning, or exterior repairs.

- The plank's strength supports workers and equipment safely at height.

- Slip-resistant surfaces improve safety on these exposed platforms.

4. Catwalks and Temporary Walkways

12 foot aluminum planks serve as temporary catwalks or walkways in industrial or event settings.

- Their durability and corrosion resistance make them suitable for outdoor or harsh environments.

- Easy to assemble and disassemble for temporary access.

5. Event Staging and Platforms

Used in concert stages, exhibition platforms, or temporary event structures.

- Provides a reliable surface for performers, equipment, or audience areas.

- Modular design allows flexible stage configurations.

Advantages Over Other Materials

| Feature | 12 Foot Aluminum Plank | Wood Plank | Steel Plank |

| Weight | Lightweight | Heavier | Heaviest |

| Strength | High | Moderate | Very High |

| Corrosion Resistance | Excellent | Poor | Susceptible to rust |

| Maintenance | Low | High | Moderate |

| Slip Resistance | Often textured or coated | Variable | Often smooth |

| Cost | Moderate to High | Low | High |

Factors to Consider When Using a 12 Foot Aluminum Plank

Load Capacity

- Rated typically for up to 500 lbs, suitable for two workers with tools.

- Always verify manufacturer specifications and do not exceed load limits.

Support Spacing

- Maximum recommended support spacing is usually 6 feet.

- Closer supports reduce bending and increase safety.

Environmental Conditions

- Aluminum planks resist corrosion and perform well outdoors.

- In wet or icy conditions, ensure slip-resistant surfaces are intact.

Proper Installation

- Secure planks firmly on scaffold frames or ladder jacks.

- Use locking mechanisms or clamps if available.

Maintenance and Safety Tips

- Inspect planks regularly for dents, cracks, or corrosion.

- Clean surfaces to maintain slip resistance.

- Store planks in dry, covered areas.

- Replace damaged planks immediately.

- Train workers on safe plank use and handling.

Extended Uses and Innovative Applications

Beyond traditional scaffolding and staging, 12 foot aluminum planks are increasingly used in innovative ways:

- Film and Photography: Platforms for camera crews to gain elevated vantage points.

- Emergency Services: Temporary walkways or platforms during rescue operations.

- Agriculture: Elevated work surfaces for orchard maintenance or greenhouse work.

- Marine Applications: Dockside platforms or temporary gangways due to corrosion resistance.

Conclusion

The 12 foot aluminum plank is a highly versatile, durable, and safe platform solution ideal for a wide range of applications including scaffolding, ladder jack setups, swing stages, catwalks, and event staging. Its lightweight yet strong construction, combined with corrosion resistance and slip-resistant surfaces, makes it a preferred choice for professionals seeking reliable working platforms. Proper use, maintenance, and adherence to load capacities ensure the plank performs safely and efficiently across various environments.

FAQ

1. What is the typical load capacity of a 12 foot aluminum plank?

Most 12 foot aluminum planks support up to 500 lbs, suitable for two workers plus equipment.

2. Can a 12 foot aluminum plank be used on ladder jack scaffolding?

Yes, it is ideal for ladder jack scaffolding, providing a secure and stable working platform.

3. Are 12 foot aluminum planks slip-resistant?

Many models have textured or coated surfaces to enhance slip resistance, improving safety.

4. How should 12 foot aluminum planks be maintained?

Regular inspection, cleaning, and immediate replacement of damaged planks are essential for safety.

5. Can 12 foot aluminum planks be used outdoors?

Yes, their corrosion resistance and durability make them suitable for outdoor use in various weather conditions.