Content Menu

● What Is a Scaffolding Fixed Coupler?

● Importance of Choosing the Right Size

● Common Outer Diameter (OD) Sizes of Scaffold Tubes and Corresponding Fixed Couplers

>> 1. OD 48.3 mm (1.5 inch) Fixed Couplers

>> 2. OD 42 mm Fixed Couplers

>> 3. OD 60 mm and OD 76 mm Fixed Couplers

>> 4. OD 89 mm Fixed Couplers

● Other Less Common Sizes

● Types of Fixed Couplers by Manufacturing Method

>> Drop Forged Fixed Couplers

>> Pressed Steel Fixed Couplers

>> Cast Fixed Couplers

● Load Capacity and Safety Standards

● Installation and Maintenance Tips

● Conclusion

● FAQ

>> 1. What is the most common size of scaffolding fixed coupler?

>> 2. Can I use a fixed coupler of one size on a different tube diameter?

>> 3. What is the difference between drop forged and pressed fixed couplers?

>> 4. How much load can a typical fixed coupler support?

>> 5. How should I maintain scaffolding fixed couplers?

Scaffolding fixed couplers are essential components in tube and clamp scaffolding systems, providing rigid and secure connections between scaffold tubes at right angles. Choosing the correct size and type of fixed coupler is crucial for scaffold stability, safety, and compliance with industry standards. This comprehensive article explores the common sizes of scaffolding fixed couplers, their specifications, applications, and considerations for selection.

What Is a Scaffolding Fixed Coupler?

A scaffolding fixed coupler (also known as a double coupler or right-angle coupler) is a mechanical fitting used to join two scaffold tubes at a 90-degree angle. It locks the tubes firmly, preventing rotation and providing structural stability. Fixed couplers are widely used to connect vertical standards to horizontal ledgers or transoms in tube and clamp scaffolding.

Importance of Choosing the Right Size

The size of the fixed coupler must match the diameter of the scaffold tubes to ensure a secure fit and maximum load-bearing capacity. Using incorrect sizes can lead to loose connections, scaffold instability, and safety hazards.

Common Outer Diameter (OD) Sizes of Scaffold Tubes and Corresponding Fixed Couplers

1. OD 48.3 mm (1.5 inch) Fixed Couplers

- Most Common Size: The OD 48.3 mm fixed coupler is the most widely used size globally.

- Applications: Standard tube and clamp scaffolding systems.

- Compatibility: Fits scaffold tubes with an outer diameter of 48.3 mm, which is the standard size for most scaffolding tubes.

- Material: Typically made from drop-forged steel or pressed steel, often hot-dip galvanized for corrosion resistance.

- Weight: Approximately 1.0 to 1.25 kg per coupler depending on manufacturing method.

- Load Capacity: Meets EN74 Class B standards, supporting loads over 30 kN.

2. OD 42 mm Fixed Couplers

- Use Case: Traditional scaffolding frames often use 42 mm diameter tubes.

- Applications: Frame scaffolding verticals and some regional standards.

- Material and Weight: Similar to 48.3 mm couplers but sized for 42 mm tubes.

- Compatibility: Japanese and some European scaffolding systems use this size.

- Load Capacity: Meets relevant local standards, slightly lower load than 48.3 mm couplers due to smaller tube diameter.

3. OD 60 mm and OD 76 mm Fixed Couplers

- Heavy-Duty Applications: Used in shoring frames, props, and heavy-duty scaffolding.

- Applications: Industrial scaffolding, formwork support, and propping systems.

- Material: Usually drop-forged steel, heavier and stronger to handle increased loads.

- Weight: Heavier than smaller sizes, can be 1.5 kg or more per coupler.

- Load Capacity: Designed for higher loads, suitable for structural support.

4. OD 89 mm Fixed Couplers

- Specialized Use: Common in the USA for sidewalk shed scaffolding and bridge supports.

- Applications: Large diameter tubes requiring robust connections.

- Material and Weight: Heaviest and strongest fixed couplers, often custom fabricated.

- Load Capacity: Highest load-bearing capacity among standard sizes.

Other Less Common Sizes

- OD 48.6 mm: Used in Japanese Industrial Standards (JIS) scaffolding.

- Custom Sizes: Some manufacturers produce fixed couplers for non-standard tube diameters, including 51 mm or 54 mm, depending on regional or project requirements.

Types of Fixed Couplers by Manufacturing Method

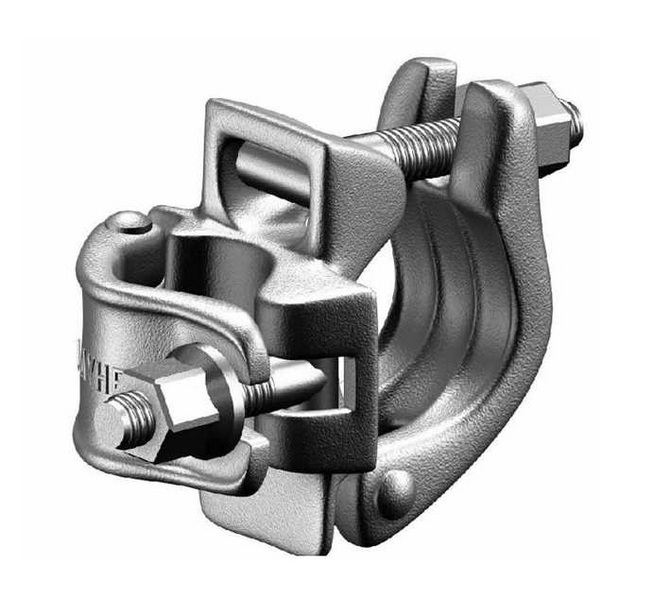

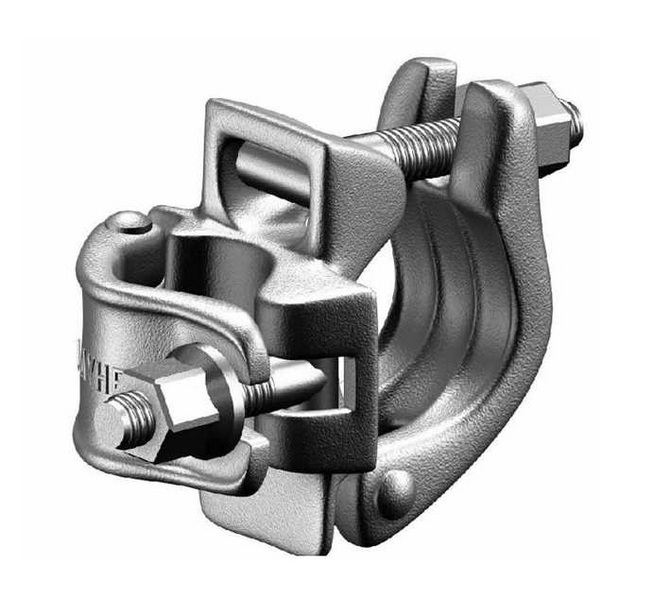

Drop Forged Fixed Couplers

- Made by forging steel under high pressure.

- Stronger and more durable.

- Weight ranges from 1.0 to 1.45 kg depending on size.

- Preferred for heavy-duty and safety-critical scaffolding.

Pressed Steel Fixed Couplers

- Made by pressing steel sheets.

- Lighter and less expensive.

- Weight ranges from 0.5 to 1.0 kg.

- Suitable for lighter scaffolding or temporary structures.

Cast Fixed Couplers

- Made by casting molten metal.

- Weight and strength vary.

- Used in some specialized scaffolding systems.

Load Capacity and Safety Standards

- Fixed couplers must comply with standards such as EN 74, BS 1139, AS/NZS 1576, and ANSI/SSFI SC100-5/05.

- Typical working load limit is around 6.25 kN (approx. 637 kgf) against slip at recommended tightening torque.

- Proper torque (usually 54 Nm) is essential to achieve rated load capacity.

- Double couplers (fixed couplers) are designed to resist tension and compression forces.

Installation and Maintenance Tips

- Use a scaffold spanner (usually 23 mm A/F) to tighten nuts to the correct torque.

- Inspect couplers regularly for corrosion, deformation, or cracks.

- Replace any damaged or worn couplers immediately.

- Store couplers in dry environments to prevent rust.

- Avoid mixing couplers from different manufacturers or standards to ensure compatibility.

Conclusion

Understanding the common sizes of scaffolding fixed couplers is fundamental for safe and efficient scaffold construction. The most prevalent size worldwide is the OD 48.3 mm fixed coupler, compatible with standard scaffolding tubes. Other sizes such as 42 mm, 60 mm, 76 mm, and 89 mm cater to specific regional standards and heavy-duty applications. Choosing the correct size and type of fixed coupler, and ensuring proper installation and maintenance, ensures scaffold stability, safety, and compliance with international standards.

FAQ

1. What is the most common size of scaffolding fixed coupler?

The most common size is OD 48.3 mm, used globally in standard tube and clamp scaffolding.

2. Can I use a fixed coupler of one size on a different tube diameter?

No, fixed couplers must match the tube diameter exactly to ensure a secure and safe connection.

3. What is the difference between drop forged and pressed fixed couplers?

Drop forged couplers are stronger and heavier, suitable for heavy-duty scaffolding, while pressed couplers are lighter and used for lighter applications.

4. How much load can a typical fixed coupler support?

Typically, a fixed coupler supports loads exceeding 6.25 kN, equivalent to about 637 kgf, when properly tightened.

5. How should I maintain scaffolding fixed couplers?

Regular inspection for damage and corrosion, proper tightening, and storage in dry conditions are essential for maintenance.