Content Menu

● Introduction to Ringlock Scaffolding

● Key Features of Ringlock Scaffolding

● Considerations Before Buying Ringlock Scaffolding

>> 1. Project Requirements

>> 2. Regulations and Standards

>> 3. Material Quality and Durability

>> 4. Cost-Effectiveness

● Applications of Ringlock Scaffolding

● Installation Process of Ringlock Scaffolding

● Safety Considerations

● Comparison with Other Scaffolding Systems

● Case Studies

● Advanced Applications

● Environmental Considerations

● Future Developments

● Conclusion

● FAQ

>> 1. What are the Key Features of Ringlock Scaffolding?

>> 2. How Does Ringlock Scaffolding Compare to Traditional Systems?

>> 3. What Materials are Used in Ringlock Scaffolding?

>> 4. Where is Ringlock Scaffolding Commonly Used?

>> 5. What are the Safety Considerations for Ringlock Scaffolding?

● Citations:

When purchasing ringlock scaffolding for sale, there are several key factors to consider to ensure that you acquire the right equipment for your construction or maintenance projects. This article will guide you through the essential considerations, including project requirements, regulatory compliance, material quality, and cost-effectiveness.

Introduction to Ringlock Scaffolding

Ringlock scaffolding is a modular system known for its versatility and efficiency. It consists of interlocking components such as vertical posts, horizontal braces, and locking rings, which provide stable and secure working platforms. The system's modular design allows for easy adaptation to different building shapes and heights, making it suitable for both simple and complex structures.

Key Features of Ringlock Scaffolding

- Modular Design: Components can be adjusted to meet different project needs.

- Interlocking System: Quick assembly and dismantling.

- Stable and Secure: Locking rings ensure components stay in place under heavy loads.

Considerations Before Buying Ringlock Scaffolding

1. Project Requirements

Before purchasing ringlock scaffolding, determine the type and scale of your projects. Consider whether you need scaffolding for a small residential project or a large industrial site. This will influence the type and quantity of scaffolding you need.

2. Regulations and Standards

Familiarize yourself with local and national regulations regarding scaffolding. Ensure that the ringlock scaffolding you purchase complies with safety standards. For projects over 5 meters, it may be necessary to hire a ticketed scaffolder to assist with design and setup.

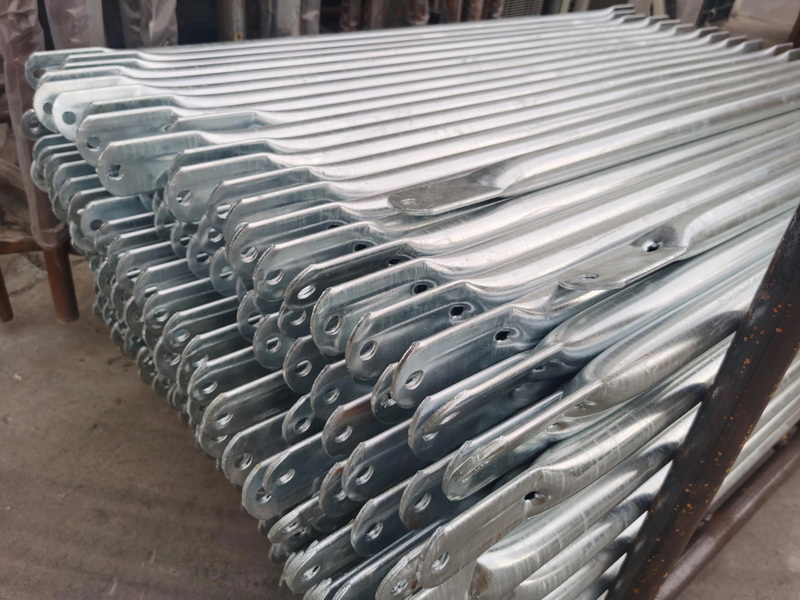

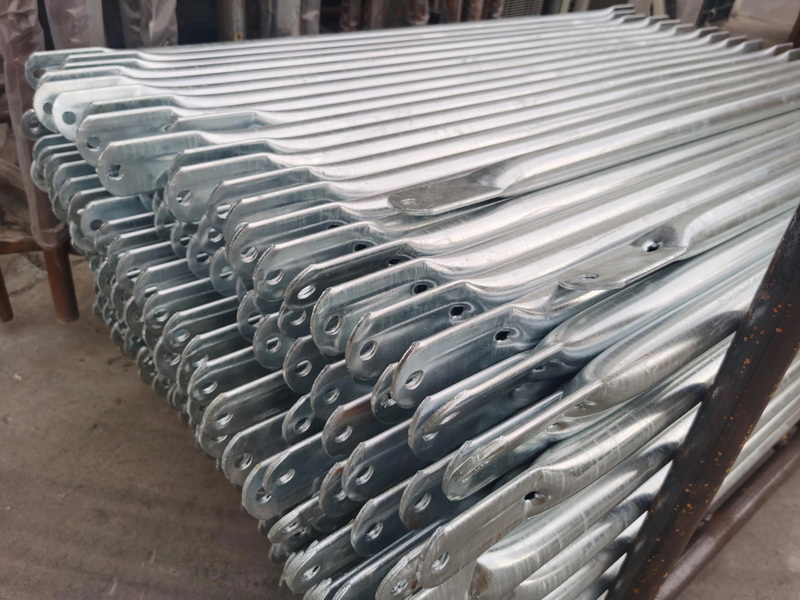

3. Material Quality and Durability

Ringlock scaffolding is typically made from high-strength steel or aluminum, with a hot-dip galvanized finish to resist rust and corrosion. This ensures a lifespan of 15–20 years without significant maintenance.

4. Cost-Effectiveness

Ringlock scaffolding is cost-effective due to its efficient assembly and dismantling process, which reduces labor costs. It also requires fewer components compared to other systems, lowering overall costs.

| Feature | Ringlock Scaffolding | Tube and Clamp Scaffolding |

| Assembly Time | Faster | Slower |

| Versatility | Higher | Lower |

| Load Capacity | Superior | Lower |

| Maintenance | Lower | Higher |

| Cost | Lower | Higher |

Applications of Ringlock Scaffolding

Ringlock scaffolding is widely used in various construction projects, including:

- Residential and commercial buildings

- Fly-over roads

- Metro stations

- Ship yards

- Petrochemical plants

Installation Process of Ringlock Scaffolding

The installation process involves several key steps:

1. Prepare the Site: Ensure the ground is flat and solid, and clear all obstacles.

2. Set Base Plates: Position base plates evenly and securely.

3. Install Vertical Standards: Insert standards into base plates and secure them.

4. Connect Horizontal Ledgers: Slide ledgers into slots on standards and lock them in place.

5. Add Diagonal Braces: Connect corners with diagonal braces for stability.

6. Install Platforms: Place platforms on top of ledgers, ensuring they are flat and secure.

7. Add Railings: Install railings around platforms for safety.

Safety Considerations

Safety is paramount when using ringlock scaffolding. Ensure all components are in good condition, and follow proper assembly and disassembly procedures. Regular inspections are crucial to maintain stability and prevent accidents.

Comparison with Other Scaffolding Systems

Ringlock scaffolding offers several advantages over traditional systems like tube and clamp scaffolding. It is faster to assemble, more versatile, and requires fewer components, which reduces costs and labor time.

Case Studies

Ringlock scaffolding has been successfully used in numerous projects worldwide, including large-scale construction sites and complex architectural designs. Its versatility and efficiency have made it a preferred choice for many contractors.

Advanced Applications

Ringlock scaffolding can also be used for specialized applications such as shoring support, facade platforms, and access towers with stairs. This versatility makes it suitable for a wide range of construction needs.

Environmental Considerations

The durability and low maintenance requirements of ringlock scaffolding reduce waste and minimize environmental impact. The hot-dip galvanized finish ensures that the scaffolding can withstand harsh weather conditions without corroding.

Future Developments

As construction technology advances, ringlock scaffolding continues to evolve with new materials and designs. Innovations in steel and aluminum alloys are expected to further enhance its strength and durability.

Conclusion

When purchasing ringlock scaffolding for sale, it is crucial to consider project requirements, regulatory compliance, material quality, and cost-effectiveness. Ringlock scaffolding offers numerous advantages, including efficient assembly, high versatility, superior load-bearing capacity, durability, and cost-effectiveness, making it a preferred choice for various construction projects.

FAQ

1. What are the Key Features of Ringlock Scaffolding?

Ringlock scaffolding features a modular design, interlocking system, and stable connections, making it suitable for various construction projects.

2. How Does Ringlock Scaffolding Compare to Traditional Systems?

Ringlock scaffolding is faster to assemble and dismantle compared to traditional tube and clamp systems, offering similar versatility but with more secure connections.

3. What Materials are Used in Ringlock Scaffolding?

Ringlock scaffolding is typically made from high-strength steel or aluminum with a hot-dip galvanized finish to resist corrosion.

4. Where is Ringlock Scaffolding Commonly Used?

It is commonly used in construction sites for residential and commercial buildings, infrastructure projects, and industrial settings.

5. What are the Safety Considerations for Ringlock Scaffolding?

Safety considerations include ensuring all components are in good condition, following proper assembly and disassembly procedures, and maintaining a safe distance from power lines.

Citations:

[1] https://rapid-scafform.com/ringlock-scaffolding/

[2] https://www.ekscaffolding.com/ringlock-scaffolding.html

[3] https://www.ringlock.co.nz/i-want-to-buy-scaffolding-what-information-do-i-need/

[4] https://www.rscaffolding.com/product-detail/ringlock-scaffolding-standards/

[5] https://www.ringlock.co.nz/safety-considerations-when-setting-up-ringlock/

[6] https://www.turboscaffolding.com.au/catalog/category-pdf/Ringlock-Technical-Manual.pdf

[7] https://apacsafety.com/ringlock-scaffolding-systems/

[8] https://apacsafety.com/ultimate-guide-of-ringlock-scaffold/

[9] https://www.doka.com/en/system-groups/doka-working-scaffold-systems/working-scaffolds/ringlock/ringlock