There is no denying that ring scaffold is highly recommended in the construction industry because it is more flexible and has higher carrying capacity. How high is the ring lock scaffold? How can we ensure safe construction on scaffolding?

What is ring lock scaffold?

What are the components of a ring lock scaffold?

How high is the ring lock scaffold?

How to use ring lock scaffolding safely?

Conclusion

What is ring lock scaffold?

Ringlock scaffolding system is one of the types of modular scaffolding. It allows workers to set up, use and dismantle temporary work structures quickly and efficiently, thereby saving time and labor costs. Ringlock is one of the most advanced and complete scaffolding systems on the market. It is designed to keep components to a minimum for easy setup and disassembly. A rose structure sits at the core of all the components. With its built-in safety mechanism and high load capacity, ring-locked scaffolding systems are a popular choice for many different types of applications.

What are the components of a ring lock scaffold?

The ringlock system is ideal for structures with complex heights and shapes. Annular scaffolding is always provided where angular flexibility is essential. It is designed to require minimal storage space. This multi-functional scaffold system is used for supporting and entering structures in construction, offshore construction, industrial maintenance and shipbuilding.

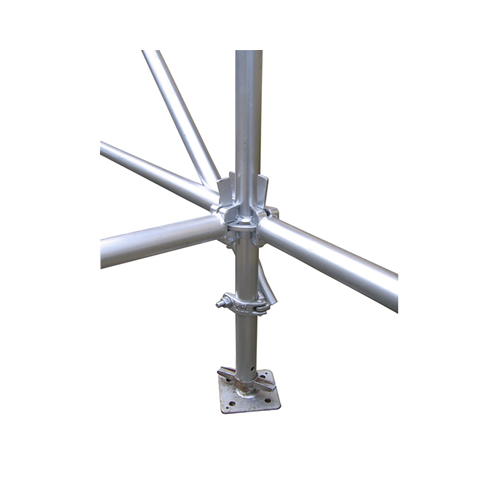

At the heart of the scaffold is a single rosette that can be connected to four supports and four horizontal lines simply by using a hammer. Ringlock can be used for circular, curved, or linear structures, as well as for mobile and stand-alone towers. The system lacks loose components that make it easy to use, maintain, and store.

The vertical column is designed to provide vertical support for scaffolding. It comes in many different sizes and can accommodate any structure. These can be bought with or without a tap. A vertical column is also called a standard.

The horizontal ledger is designed to provide horizontal support for platforms and loads. They can also be used as guardrails for safety reasons. They also come in various sizes to suit a variety of situations.

Diagonal bracing is used to provide lateral bracing for the support. They can also be used as stair systems or guardrails for tension and compression components.

The rotary fixture bracket is also used for lateral support of the bracket. In addition, it can be used as an obtuse guardrail in the stair system.

The truss ledger is designed to increase the strength of scaffolding and to withstand more weight.

The screw or base jack is the starting point of the annular scaffold. It is adjustable to allow variations in height when working on uneven surfaces.

Casters are used to make scaffolding towers that can roll and move from one point to another.

The step-down bracket is used to generate 250mm of step-down and can be attached to the baseboard or base lift.

When it is not possible to use the main bracket, the riser bracket is used to extend the platform to get closer to the structure.

The steel plate is responsible for creating the platform on which the workers actually stand. They are placed side by side, and the number of planks used determines the width of the platform.

The filler board is designed to create links between multiple workplatforms. They also prevent tools and other materials from falling off the platform.

Stair girders serve as diagonal sections of the circular stair system, and they also serve as connecting points for stair treads.

Storage racks and baskets. These components add flexibility and ease of use to work on annular brackets. As the name makes clear, these can be used to keep tools and other materials in one place to make the job easier.

A range of accessories can be added to ringlock scaffolding to make it easier to use or easier to use. Some of them include:

Rosette: used to add rosettes to any point on a vertical tube.

Davit Arm: this is a very useful component that can be used when lifting light loads with metal wheels.

Casing adapter clamp: allows connection of annular vertical parts at intermediate points such as truss ledger.

Rotary adapter clamp: this clamp can be used to connect the pipe to a single garland at various angles.

Switch pins: these pins lock the bottom and top vertical tubes together.

How high is the ring lock scaffold?

The height of ring lock scaffolding, according to national standards, there are no strict restrictions, but there is a set of specifications on the height of ring lock scaffolding. Regular scaffolding manufacturers in the setting of the factory scaffolding price, there will be factory inspection report, which is the use of more mobile scaffolding and overseas use of more export scaffolding have different inspection requirements.

Scaffold pole foundation shall meet the requirements of the scheme.

1.When the height is 25m or less, it can be rammed and leveled, and 5cm thick board is laid on it. When the length is 2m, it is placed perpendicular to the wall. When the length is greater than 3m, it shall be placed parallel to the wall.

2 when the construction height is 25-50m, the foundation method should be designed according to the field endurance or when backfill is adopted to meet the requirements, sleepers can be used to support the cushion, or 20cm thick ballast can be laid on the foundation, on which concrete slabs shall be laid, and channel 12-16 steel shall be laid.

3. When the erection height exceeds 50m, calculation should be made and the foundation design should be based on the endurance method, or a lime soil foundation should be adopted at a depth of 1m below the ground, or a concrete foundation 50m thick should be poured, and pillow cushion should be applied on the foundation.

When the vertical pole is not buried and 20cm above the ground, it is the same as the large horizontal pole to set the vertical and horizontal sweeping bar with no need to set the sweeping bar. Its function is to fix the bottom of the vertical pole and restrain the horizontal position and subsidence.

Wooden scaffold made 杄 buried, don't set 杄 sweeps the floor. Buried in a depth of 30-50cm. The bottom of the pit should be rammed with broken bricks, and backfill in the pit should be rammed in layers.

Scaffold based low-lying, consideration should be given no drainage measures, wooden scaffold made 杄 buried after backfill soil mass above the ground shall be maintained, to prevent the bottom water.

How to use ring lock scaffolding safely?

Scaffolds shall be assembled under the supervision and direction of qualified personnel.

Provide safe ladder access - workers should not climb on supports or structural components/frames.

Scaffold grade timber was used to create the platform.

Install sheeting and sheeting (whichever is smaller) on all scaffolds 10 feet from the ground or 2 frames.

Competent personnel train all personnel on safe scaffold use.

Ensure that the structure can support up to four times the maximum expected load, including its own weight.

Conclusion

Understanding the components of the ring lock scaffold and the rules for its use can help protect the safety of scaffolding workers, but it is also essential to choose a qualified ring lock scaffold that meets the standards. If you need a better, safer, and precision-tested ring lock scaffold, Nanjing Tuopeng Construction Technology can provide you with the perfect product.