Frame scaffolding is probably the most commonly used scaffolding system in the construction industry and the main product of all scaffolding system suppliers. The mason frame scaffolding, although widely used, is not understood by most people. Do you know that there is more than one mason frame scaffolding? What is its purpose?

What is the use of mason frame scaffolding?

What are the advantages of mason frame scaffolding?

How heavy is the masonry frame scaffold?

What should I pay attention to before accessing the frame scaffolding?

Conclusion

What is the use of mason frame scaffolding?

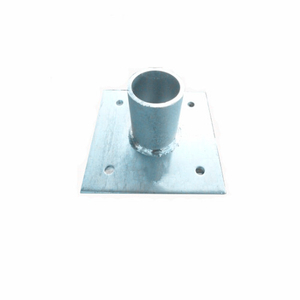

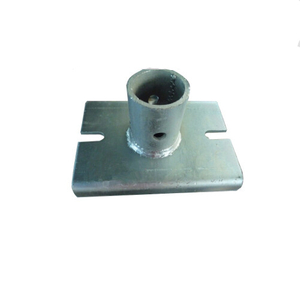

Mason frame scaffolding is a common industry term referring to our popular frame and support scaffolding. From carpenters, masons to owners of weekend projects, all types of contractors use this most common scaffolding to make bricks or blocks safer and more efficient. It is easy to install and remove, allowing you to reach the required height quickly.

Masonry generally uses mason frame scaffolding. They are usually used by one or two-story residential contractors, painters, etc., but their modular framework can also be stacked several times in large construction projects. In the mason frame scaffolding, there are two standard frames, 1.5 m from the first standard. The mason frame scaffolding is completely independent of the stone wall.

Mason frame scaffolding is used to carry heavy objects because the weight on the stone is heavy. Therefore, the stonemason frame scaffolding is made stronger by placing the standard at a fairly close distance.

What are the advantages of mason frame scaffolding?

1. Mason frame scaffolding consists of two ladder frames, two pairs of crossbars and four connecting pins.

2. The second step. Framed scaffolding is easy to assemble and disassemble, saving time and effort.

3. Workers can climb the ladder smoothly and safely without the need for additional ladders.

Chapter Four. The trapezoidal mason frame scaffolding is especially suitable for brick wall construction, exterior wall painting or plastering works. It is easy to operate and can be moved with the casters.

How heavy is the masonry frame scaffold?

The weight of the mason frame scaffolding is not strictly limited according to national standards, but there is a set of specifications for the maximum load of the scaffold.

Maximum expected load. Each scaffold and scaffolding assembly should be capable of supporting its own weight without damage and at least four times the maximum expected load applied or transmitted to the scaffolding. In order to calculate the maximum expected load, the total weight of all personnel, equipment, tools, materials, transfer loads and other loads applied to the scaffold (or scaffolding components) is reasonably expected at all times. (estimated 250 pounds per person.)

Rated load capacity. The loading of scaffold and scaffolding components must not exceed their maximum expected load or rated capacity, whichever is less. The rated load capacity of the bracket is defined as follows.

Rated load capacity

Scaffolding rated load capacity

Should be the expected load

relaxing work

The maximum weight that can be applied to the bracket is determined by the data provided by the manufacturer and is expressed as an allowable load per square foot (eg, 25 psf, 50 psf or 75 psf, multiplied by the square feet of the working surface of the bracket).

A simple method of overloading to determine if the stent is overloaded is the deflection method. When loading, the deviation of the platform, wood or trim panel shall not exceed 1/60 of the span. The deflection is measured with a tape measure and a straight edge.

Implementation: The bracket has shelves that are supported on a 10 foot support (ie, a 10 foot or 120 inch span). 120 inches multiplied by 1/60 equals 2 inches maximum deflection. If the panel is bent more than two inches below the weight applied to the board, the scaffold is overloaded.

What should I pay attention to before accessing the frame scaffolding?

What will the scaffold be used for? For example, light (one or two workers; painted walls) or heavy (several businessmen, large and heavy materials on the platform)?

How high is the scaffolding? Will it be established in one operation or as the work progresses?

Ground company? Can it support the load on scaffold, workers and materials?

Do you need to bundle the scaffold? How to do it? Will the relationship be moved as the work progresses?

Is the scaffold likely to be covered or enclosed as a protection for the elements? Is there a provision for adding additional links to adjacent structures?

What is the method of accessing and exporting? For example, a sloping ladder, a vertical ladder, a built-in staircase, or directly from the floor of a building?

How many levels of material can I load on a multi-layer scaffold? Do you require engineers to calculate the total expected load and possibly design scaffold and thresholds?

If you need to roll the scaffold, consider the ground, the height limit when moving (3 to 1 rule) danger (such as wires, building projections and potholes).

Conclusion

Understanding the characteristics of the mason frame scaffolding allows you to use it better, and don't forget to carefully calculate its load capacity, and prepare everything before construction to ensure the safety of the construction personnel. If you are looking for durable, sturdy, reasonably priced high quality mason frame scaffolding, Nanjing Tuopeng Construction Technology can provide you with the perfect product.