Ringlock is one of the most advanced and complete scaffolding systems on the market and a popular choice for many different types of applications. But before you consider buying ring lock scaffolding, you may be confused about what exactly is the standard for ringlock scaffolding?

Ringlock scaffolding standard

Ringlock scaffolding features

Conclusion

Ringlock scaffolding standard

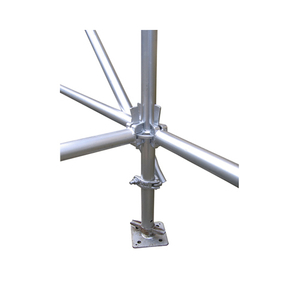

The ringlock scaffold standard with rose wreath and connecting pin is the vertical component of the ringlock system scaffold tower.

Ringlock scaffold standard coupling pin is fixed with nut class 8.8 or pressed-in bolt.

According to Rosette Ring Shape, the ringlock scaffolding standard applies to different countries, including USA and Canada, Singapore, New Zealand, Chile, European Layher, etc.

Ringlock scaffolding standards are tested according to EN12810 and AS1576 building scaffolding standards.

Ringlock scaffolding standards include OD 48.3mm normal load and OD 60.3mm heavy-duty support system based on allowable tubular size and carrying capacity.

Ringlock scaffolding is also known as Pin Lock System modular Scaffolding. Used for all kinds of construction, such as civil, infrastructure, industrial, oil and gas, commercial, bridge, highway, support, formwork concrete temporary support, etc.

The surface treatment is always hot dip galvanized. Different colors of paint and powder coatings are available upon request.

The welding quality of the ring scaffold standard conforms to the CE certification standards en1090-1 and ISO 3834-2

Ringlock scaffolding features

The ring lock looks like a flat round piece of metal. It has nine openings, including one in the middle and eight on the periphery, giving it the appearance of a petaled flower (hence the name). With many openings, a ring lock can accommodate many connections. These also allow the rod to be placed in a curved structure, or at an Angle of 45° or 90°.

Because they can connect multiple components together, the ring brackets create a variety of custom accessories. We often use them for special events (bleachers), industrial sectors (confined Spaces), or when certain obstacles (such as Bridges, towers, and buildings on irregular slopes) prevent us from installing other types of scaffolding. In other words, ring-locked scaffolding is an ideal solution for more complex projects.

Why is ring lock scaffold popular?

1. Annular scaffold node structure is reasonable, axial force, force bar makes scaffold in three-dimensional space, the overall structural strength is high, the overall stability is good, with reliable self-locking performance, can better meet the construction needs of scaffold safety.

2. Reduce the cost, can use the existing fastener-type steel pipe scaffold equipment for renovation, greatly reduce the update cost.

3.Ring lock scaffold components uniform size, scaffolding erection with standardization, standardization, suitable for site civilized construction characteristics; With ringlock and bar as a whole, bulk and loss cost are avoided and field management is convenient.

4. High efficiency and reduction of labor intensity, operation level, connection speed is 2-3 times faster than the traditional scaffold installation, workers only need a small hammer can complete all homework, can reduce the labor intensity of 0.5 times.

5. Simple maintenance, because ringlock scaffold completely avoids bolt operation, inadvertently missing parts, parts easy to carry, strong, by touch collision approval, general corrosion does not affect the operation, simple installation and maintenance, easy to transport.

6. Ring scaffold group is flexible and applicable to a wide range. According to construction requirements, it can be composed of various groups of sizes of 0.6m and load modules such as single row, double row scaffold, bracket and material lifting. Multi-functional scaffold construction equipment, can do curve decoration, can also be used on the ground any difference, according to different load requirements, flexible adjustment of the bracket spacing.

Conclusion

Ring lock scaffolding because of its excellent bearing capacity and safety by people's appreciation, learn about the ring lock scaffolding standards can make it easier for you to pick up quality scaffolding and use it safely. If you need a better, safer, and precision-tested ring lock scaffold, Nanjing Tuopeng Construction Technology can provide you with the perfect product.