Content Menu

● What is a 2x10 Aluminum Plank?

● Why Doesn't Aluminum Rust?

● Durability: How Long Do 2x10 Aluminum Planks Last?

>> Lifespan and Structural Integrity

>> Outdoor and Industrial Use

● Maintenance and Cleaning

>> How to Keep 2x10 Aluminum Planks in Top Shape

>> Built for Strength and Security

>> Is a 2x10 Aluminum Plank Worth the Investment?

>> How to Install and Use 2x10 Aluminum Planks

>> Aluminum: A Green Building Material

>> What Do Real Users Say?

● Conclusion

● FAQ

>> 1. Are 2x10 aluminum planks truly rust-proof?

>> 2. How much weight can a 2x10 aluminum plank support?

>> 3. Do aluminum planks require special maintenance?

>> 4. Can 2x10 aluminum planks be used outdoors year-round?

>> 5. Are 2x10 aluminum planks safe for scaffolding and elevated work?

Aluminum planks, especially in the 2x10 size, have become a cornerstone in construction, scaffolding, decking, and a variety of industrial and residential applications. Their reputation for being rust-proof and long-lasting makes them a preferred choice over traditional materials like wood and steel. But what makes a 2x10 aluminum plank so durable? Are they truly rust-proof? How do they perform in harsh environments? This comprehensive guide explores these questions in depth, supported by technical insights, real-world comparisons, and practical advice.

What is a 2x10 Aluminum Plank?

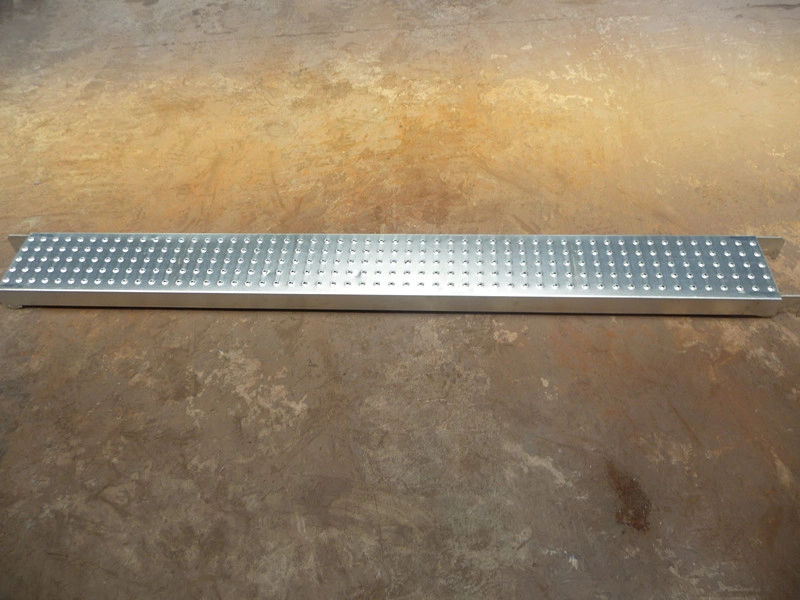

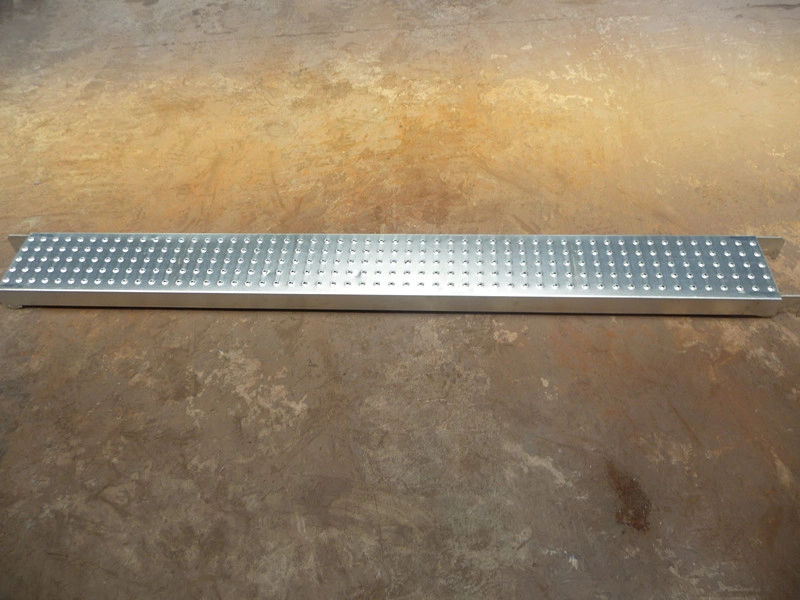

A 2x10 aluminum plank refers to a plank that is approximately 2 inches thick and 10 inches wide, commonly used as a platform in scaffolding, walkways, decking, and more. These planks are typically made from high-grade aluminum alloys, such as 6061-T6, prized for their strength-to-weight ratio and resistance to environmental damage.

Key Features:

- Lightweight yet strong

- Slip-resistant surfaces (grooved or perforated)

- Corrosion and rust resistance

- Easy to transport and install

- Available in various lengths to suit different applications

Why Doesn't Aluminum Rust?

Unlike iron or steel, aluminum does not rust. Rust is the result of iron reacting with oxygen and water to form iron oxide. Aluminum, on the other hand, naturally forms a thin, hard oxide layer (aluminum oxide) when exposed to air. This layer acts as a protective barrier, preventing further oxidation and corrosion.

Comparison Table: Rust and Corrosion Resistance

| Material | Rusts? | Corrosion Resistance | Maintenance Needs |

| Aluminum | No | Excellent | Low |

| Steel | Yes | Poor (unless coated) | Moderate |

| Wood | No | Poor (rots, decays) | High |

Durability: How Long Do 2x10 Aluminum Planks Last?

Lifespan and Structural Integrity

A well-made 2x10 aluminum plank can last 15-20 years or more, even in demanding environments. The 6061-T6 aluminum alloy commonly used is engineered for high tensile strength, impact resistance, and minimal flexing under heavy loads.

Key Durability Factors:

- Resistant to warping, cracking, and splintering

- Unaffected by rot, mold, or insect damage

- Maintains structural integrity in extreme temperatures and UV exposure

Real-World Example:

"Aluminum scaffold planks have been tested to support uniform loads exceeding 9,000 lbs, far surpassing OSHA's heavy-duty standards. Their resistance to rust and corrosion means they do not need protective coatings or frequent replacement."

Outdoor and Industrial Use

2x10 aluminum planks excel in harsh weather and corrosive environments, such as:

- Heavy rain, snow, and ice

- Coastal areas with salt exposure

- Chemical plants with acids and alkalis

Why?

- Aluminum's oxide layer shields it from moisture and chemicals

- Grooved surfaces provide slip resistance even when wet or icy

Maintenance and Cleaning

How to Keep 2x10 Aluminum Planks in Top Shape

Aluminum planks are low-maintenance, but regular cleaning preserves their appearance and slip resistance.

Maintenance Tips:

- Sweep debris regularly with a broom or leaf blower

- Wash with mild soap and water; avoid bleach or harsh chemicals

- Inspect for dents, scratches, or loose hardware

- Apply UV-resistant coatings if exposed to intense sunlight

- Use a rubber-edged snow shovel in winter to avoid scratches

Built for Strength and Security

2x10 aluminum planks are engineered for safety:

- Slip-resistant surfaces (grooved or perforated)

- High load capacity: typically 50-75 lbs per square foot, with some models tested to over 9,000 lbs uniform load

- Reinforced edges and flanges for extra rigidity

- Lightweight for easy handling, reducing risk of injury

Comparison Table: Load Capacity and Safety:

| Plank Type | Typical Load Capacity | Slip Resistance | Weight | Safety Features |

| Aluminum | 500-9000+ lbs | Excellent | Lightweight | Grooved surface, handles |

| Wood | Varies, lower | Variable | Heavy | May splinter, rot |

| Steel | High, but rusts | Variable | Heaviest | Needs coating |

Is a 2x10 Aluminum Plank Worth the Investment?

While 2x10 aluminum planks have a higher upfront cost than wood, their longevity and minimal maintenance reduce overall expenses.

Cost Comparison Over 10 Years

| Material | Initial Cost | Maintenance Cost | Lifespan | Total 10-Year Cost |

| Aluminum | High | Low | 15-20+ years | Moderate |

| Wood | Low | High | 2-5 years | High |

| Steel | Moderate | Moderate | 10-15 years | Moderate to High |

How to Install and Use 2x10 Aluminum Planks

One of the major advantages of 2x10 aluminum planks is their versatility and ease of installation. Whether you're building a deck, setting up scaffolding, or creating a temporary walkway, these planks can be adapted to a wide range of uses.

Installation Tips:

- Use brackets or clamps designed for aluminum planking to secure them in place.

- For scaffolding, ensure the planks are properly seated in the frame and locked.

- When used as decking, fasten with stainless steel or aluminum screws to prevent galvanic corrosion.

- Always check for proper support spacing according to the manufacturer's load ratings.

Versatile Applications:

- Scaffolding platforms

- Walkways over uneven terrain

- Boat docks and piers

- Temporary stages or event flooring

- Permanent or temporary decking

Aluminum: A Green Building Material

Sustainability is a growing concern in construction. Aluminum stands out as an environmentally friendly option:

- Recyclability: Aluminum is 100% recyclable without loss of quality. Most new aluminum products contain a significant percentage of recycled material.

- Energy Efficiency: Manufacturing recycled aluminum uses only about 5% of the energy required to produce new aluminum from ore.

- Longevity: The long lifespan of a 2x10 aluminum plank means fewer replacements and less waste compared to wood or steel.

What Do Real Users Say?

Testimonial 1: Construction Contractor

"Switching to 2x10 aluminum planks for our scaffolding was a game-changer. They're lighter, easier to move, and we haven't had to replace a single one in five years, even with heavy daily use."

Testimonial 2: Homeowner

"I used 2x10 aluminum planks to build a walkway over a marshy area in my backyard. After several harsh winters, they still look and function like new. No rust, no rot, and no worries!"

Testimonial 3: Event Organizer

"Setting up temporary stages is much easier with aluminum planks. The slip-resistant surface is a big plus for safety, and we save money on replacements."

Conclusion

2x10 aluminum planks are indeed rust-proof and exceptionally long-lasting. Their natural oxide layer shields them from corrosion, while their engineered strength ensures they can handle heavy loads and harsh environments for decades. Compared to wood and steel, aluminum planks offer superior durability, safety, and cost-effectiveness over their lifespan. With minimal maintenance and excellent performance in any weather, they are the top choice for professionals and DIYers alike seeking a reliable platform for construction, decking, and more.

Additionally, their environmental benefits and recyclability make them a responsible choice for the future. Whether you need a plank for scaffolding, decking, or a custom project, the 2x10 aluminum plank stands out as a smart, sustainable, and long-lasting investment.

FAQ

1. Are 2x10 aluminum planks truly rust-proof?

Yes, aluminum does not rust like steel. Instead, it forms a protective oxide layer that prevents corrosion, making 2x10 aluminum planks ideal for wet or humid environments.

2. How much weight can a 2x10 aluminum plank support?

Most 2x10 aluminum planks are rated for 50-75 lbs per square foot, with some models tested to support over 9,000 lbs in uniform load tests. Always check the manufacturer's specifications and follow OSHA guidelines.

3. Do aluminum planks require special maintenance?

Maintenance is minimal. Regular cleaning with mild soap and water, prompt repair of dents or scratches, and periodic inspection for loose hardware are recommended. Avoid harsh chemicals and abrasive tools.

4. Can 2x10 aluminum planks be used outdoors year-round?

Absolutely. Their corrosion resistance and structural integrity make them suitable for outdoor use in all climates, including coastal, industrial, and winter conditions.

5. Are 2x10 aluminum planks safe for scaffolding and elevated work?

Yes, when installed according to manufacturer and OSHA guidelines, 2x10 aluminum planks provide a safe, stable, and slip-resistant platform for construction and maintenance work.