Content Menu

● Introduction to the Parts of Scaffolding Frame

● What Does “Standardized” Mean for Scaffolding Frame Parts?

● Key Parts of Scaffolding Frame and Their Standardization

>> 1. Standards (Uprights/Verticals/Legs)

>> 2. Ledgers (Runners)

>> 3. Transoms (Bearers/Putlogs)

>> 4. Base Plates and Sole Plates

>> 5. Bracing (Cross Braces, Diagonal Braces)

>> 6. Decking/Platforms

>> 7. Guardrails and Toe Boards

>> 8. Coupling Pins and Connectors

● Are All Scaffolding Frame Parts Interchangeable?

>> Manufacturer and System Differences

>> International and Regional Standards

>> Mixing Parts from Different Manufacturers

● Why Aren't All Parts of Scaffolding Frame Standardized?

● Industry Standards and Best Practices

>> International Standards

>> U.S. Standards

● Practical Implications on the Job Site

● Expanding the Discussion: Modular Innovations and Digital Integration

>> Digital Planning and BIM Integration

>> Sustainability and Lifecycle Management

>> Training, Certification, and Safety Culture

● Conclusion

● FAQ

>> 1. What are the main parts of scaffolding frame and their functions?

>> 2. Can I mix parts of scaffolding frame from different manufacturers?

>> 3. Are there global standards for scaffolding frame parts?

>> 4. How do I identify if my scaffolding frame parts are compatible?

>> 5. What happens if I use non-standard or incompatible parts in my scaffold frame?

Scaffolding is a critical component in construction, maintenance, and industrial projects, providing safe access and support for workers at height. The question of whether all parts of scaffolding frame systems are standardized is essential for safety, compatibility, and efficiency on job sites worldwide. This article offers a comprehensive exploration of the standardization of scaffolding frame parts, examining industry practices, international standards, compatibility challenges, and best practices.

Introduction to the Parts of Scaffolding Frame

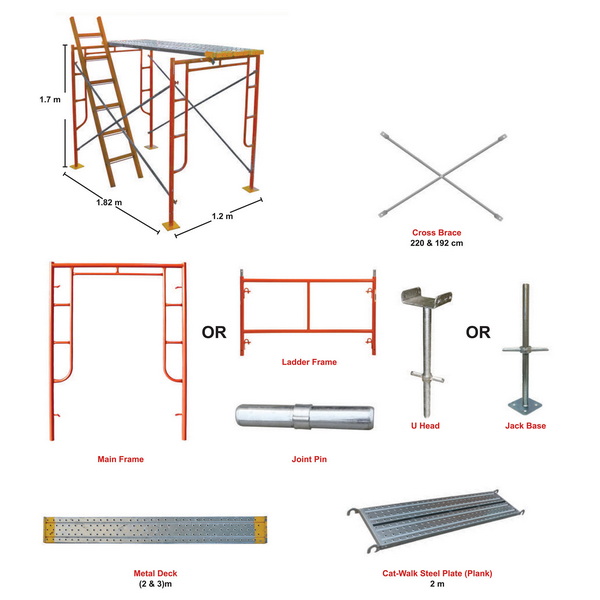

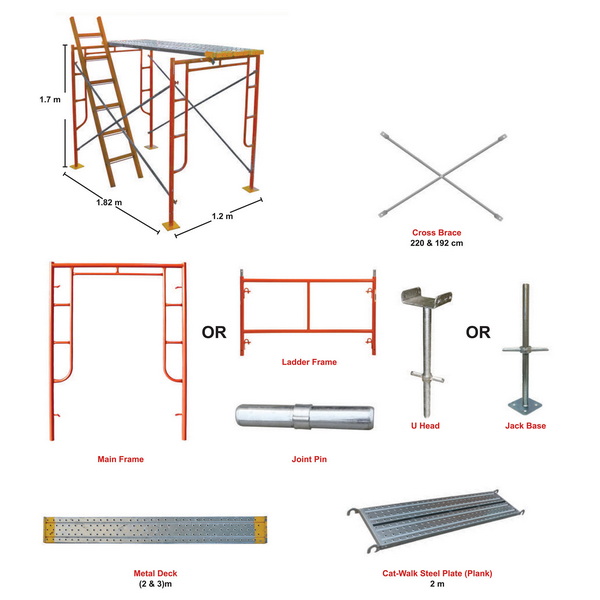

The parts of scaffolding frame are the building blocks of any scaffold structure. These components must work together to ensure the scaffold is safe, stable, and fit for purpose. The main parts include:

- Standards (Uprights/Verticals/Legs)

- Ledgers (Runners)

- Transoms (Bearers/Putlogs)

- Base Plates and Sole Plates

- Bracing (Cross Braces, Diagonal Braces)

- Decking/Platforms

- Guardrails and Toe Boards

- Coupling Pins and Connectors

- Accessories (Ladders, Casters, Outriggers, etc.)

What Does “Standardized” Mean for Scaffolding Frame Parts?

Standardization refers to the adoption of uniform specifications for design, dimensions, materials, and performance, ensuring that parts are interchangeable and meet safety and quality benchmarks. In scaffolding, standardization is vital for:

- Safety: Ensuring all parts of scaffolding frame meet load and stability requirements.

- Interchangeability: Allowing components from different batches or suppliers to fit together.

- Compliance: Meeting regulatory requirements (OSHA, ANSI, ISO, EN, etc.).

- Efficiency: Simplifying assembly, inspection, and maintenance.

Key Parts of Scaffolding Frame and Their Standardization

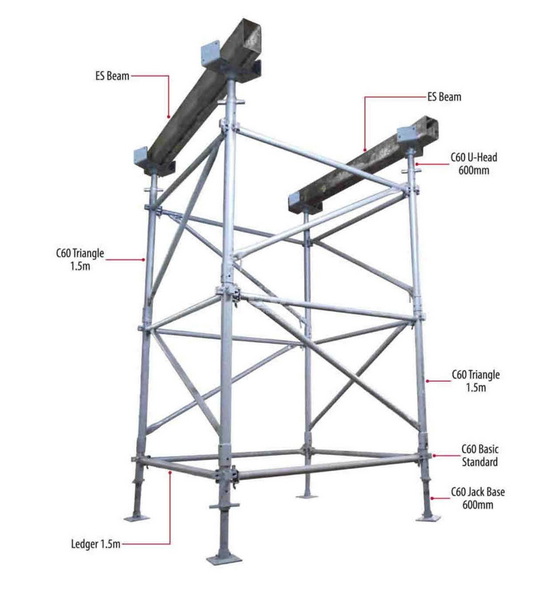

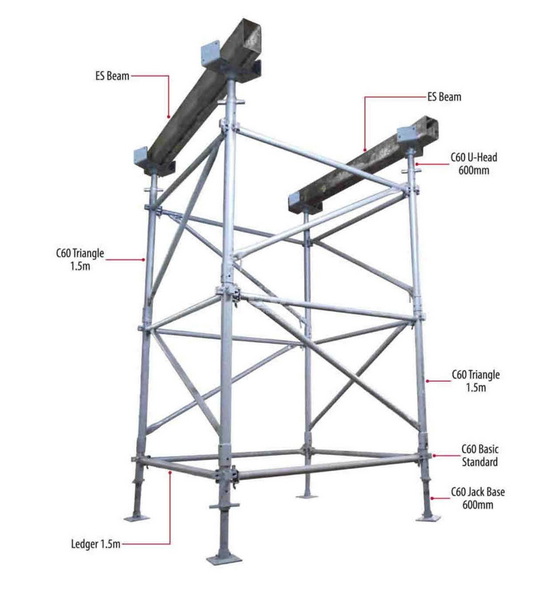

1. Standards (Uprights/Verticals/Legs)

Standards are the vertical tubes that transfer the scaffold's weight to the ground, typically through a base plate. Most standards are manufactured to common diameters (e.g., 48.3mm or 1.90 inches) and thicknesses (often 4mm), but there can be variations depending on regional standards and manufacturer practices.

2. Ledgers (Runners)

Ledgers are horizontal tubes connecting the standards and supporting the platform. Their length and diameter are often standardized within a system, but may differ between manufacturers or regions.

3. Transoms (Bearers/Putlogs)

Transoms span across ledgers at right angles and support the platform boards. Like ledgers, their dimensions are often system-specific but follow industry norms for strength and compatibility.

4. Base Plates and Sole Plates

Base plates distribute the load from the standards to the ground, while sole plates provide additional support on soft or uneven surfaces. The size, shape, and material of base plates are typically standardized to fit the standards they support.

5. Bracing (Cross Braces, Diagonal Braces)

Bracing is essential for scaffold stability. Braces are made to specific lengths and connection types to match the frame system, but the locking mechanisms and lengths can vary significantly between brands and systems.

6. Decking/Platforms

Platforms, often made from steel, aluminum, or wood, are designed to fit specific frame widths and support designated loads. The width, length, and locking features are standardized within a system but not always across different systems.

7. Guardrails and Toe Boards

Guardrails and toe boards are safety components that prevent falls and dropped tools. Their height and strength are governed by standards (e.g., OSHA, EN), but attachment methods may differ.

8. Coupling Pins and Connectors

Coupling pins join standards or frames vertically. Their diameter, length, and locking features are system-specific, and not all pins are interchangeable across manufacturers.

Are All Scaffolding Frame Parts Interchangeable?

The short answer: No, not all parts of scaffolding frame are universally standardized or interchangeable. While there are industry standards and common dimensions, real-world compatibility depends on several factors:

Manufacturer and System Differences

- Frame Styles: Major frame styles in the U.S. include Safeway, Waco, and Bil-Jax, each with unique leg diameters, pin hole locations, and brace locks.

- Tube Diameters: Even small differences (e.g., 1.625” vs. 1.69”) can prevent proper fit.

- Pin and Lock Types: Coupling pins may have different collars, lengths, and locking mechanisms.

- Bracing Stud Spacing: Cross brace stud spacing and attachment points can vary.

International and Regional Standards

- OSHA (U.S.), EN (Europe), ISO (International): These bodies set minimum requirements for dimensions, materials, and safety, but allow for manufacturer-specific designs.

- ISO 9001 & ISO 1461: Focus on quality management and galvanized steel, ensuring safety and durability but not full part interchangeability.

Mixing Parts from Different Manufacturers

OSHA allows mixing parts of scaffolding frame from different manufacturers only if a competent person determines the resulting scaffold is structurally sound. Manufacturers and industry associations provide guidelines, but responsibility lies with the scaffold erector and inspector.

Why Aren't All Parts of Scaffolding Frame Standardized?

- Proprietary Designs: Manufacturers develop unique features for safety, strength, or ease of use.

- Regional Preferences: Different markets favor certain frame styles or connection methods.

- Application-Specific Needs: Heavy-duty, light-duty, facade, and shoring scaffolds require different specifications.

- Historical Evolution: Long-standing brands have legacy systems that persist in the field.

Industry Standards and Best Practices

International Standards

- ISO 9001: Quality management in design and production of scaffolding frames.

- ISO 1461: Galvanized steel requirements for corrosion resistance.

- EN 12811 (Europe): Temporary works equipment standards, including load classes and design.

U.S. Standards

- OSHA 1926 Subpart L: Specifies requirements for supported scaffolds, including parts of scaffolding frame, load capacity, and safety features.

- ANSI/SSFI: Additional guidelines on design, testing, and use.

Practical Implications on the Job Site

- Always use parts of scaffolding frame from the same manufacturer and system when possible.

- If mixing is necessary, consult manufacturer guidelines and have a competent person verify structural integrity.

- Inspect all parts for compatibility, damage, and wear before assembly.

- Follow local and international standards for assembly, use, and dismantling.

Expanding the Discussion: Modular Innovations and Digital Integration

Digital Planning and BIM Integration

The construction industry is increasingly adopting digital tools and Building Information Modeling (BIM) to plan and manage the assembly of parts of scaffolding frame. These technologies allow project managers and engineers to:

- Visualize scaffold layouts in 3D

- Detect potential clashes with building elements

- Optimize material usage and logistics

- Ensure compliance with safety and compatibility standards

Sustainability and Lifecycle Management

Modern scaffolding systems are designed for reusability and sustainability. Many manufacturers use recycled steel and environmentally friendly coatings, and they design parts of scaffolding frame for easy disassembly and reuse on multiple projects. Proper lifecycle management—including routine inspection, maintenance, and storage—extends the service life of each component and supports sustainable construction practices.

Training, Certification, and Safety Culture

A key aspect of safe and effective scaffolding use is comprehensive training and certification. Industry-leading programs cover:

- Identification and selection of compatible parts of scaffolding frame

- Safe assembly and dismantling procedures

- Inspection routines and hazard recognition

- Emergency response protocols

A strong safety culture, reinforced through ongoing education, ensures that all workers understand the risks of mixing non-standard parts and the importance of using certified, compatible components.

Conclusion

While there are industry standards that guide the parts of scaffolding frame—such as dimensions, materials, and load capacities—not all parts are universally standardized or interchangeable. Differences in manufacturer design, regional preferences, and application-specific requirements mean that careful attention must be paid to compatibility and compliance. Always follow best practices: use matched systems, consult manufacturer documentation, and ensure all assemblies are inspected by a competent person. This approach ensures safety, efficiency, and regulatory compliance on every project.

FAQ

1. What are the main parts of scaffolding frame and their functions?

The main parts of scaffolding frame include standards (vertical supports), ledgers (horizontal supports), transoms (platform bearers), base plates (load distribution), bracing (stability), decking/platforms (work surfaces), guardrails, toe boards, and connectors. Each part has a specific role in maintaining scaffold integrity and safety.

2. Can I mix parts of scaffolding frame from different manufacturers?

Mixing is only allowed if a competent person determines the assembly is structurally sound. Differences in tube diameter, pin types, and brace spacing often prevent safe interchangeability. Always consult manufacturer guidelines and standards before mixing parts.

3. Are there global standards for scaffolding frame parts?

Yes, ISO 9001 and ISO 1461 set international standards for quality management and galvanized steel, while EN 12811 (Europe) and OSHA (U.S.) provide regional requirements for design, assembly, and safety.

4. How do I identify if my scaffolding frame parts are compatible?

Check for matching tube diameters, pin hole locations, brace locks, and manufacturer markings. If in doubt, consult the manufacturer or a competent scaffolding inspector.

5. What happens if I use non-standard or incompatible parts in my scaffold frame?

Using incompatible or non-standard parts can compromise scaffold strength, stability, and safety, increasing the risk of collapse or failure. This can result in regulatory violations, accidents, or project delays. Always use compatible, certified parts and follow best practices for assembly and inspection.