Content Menu

● Introduction

● What Is a Black Scaffolding Tube?

● Material Properties and Manufacturing

● Are Black Scaffolding Tubes Rust-Resistant?

● Surface Treatments and Coatings

>> 1. Painted Scaffolding Tubes

>> 2. Galvanized Scaffolding Tubes

>> 3. Powder Coating and Oiling

● Comparison: Black vs. Galvanized vs. Painted Scaffolding Tubes

● Applications and Best Practices

>> Where Are Black Scaffolding Tubes Used?

>> Best Practices:

● Maintenance and Inspection of Black Scaffolding Tubes

>> Inspection:

>> Cleaning:

>> Storage:

>> Documentation:

● Black Scaffolding Tube in Modern Construction Projects

>> Role in Modular Scaffold Systems

>> Cost-Driven Projects

>> Custom Fabrication and Adaptability

>> Environmental Considerations

● Environmental and Economic Considerations

>> Economic Factors

>> Environmental Impact

● Conclusion

● FAQ

>> 1. Are black scaffolding tubes rust-resistant by themselves?

>> 2. Can black scaffolding tubes be used outdoors?

>> 3. How can I protect black scaffolding tubes from rust?

>> 4. What is the difference between black, painted, and galvanized scaffolding tubes?

>> 5. How should black scaffolding tubes be maintained?

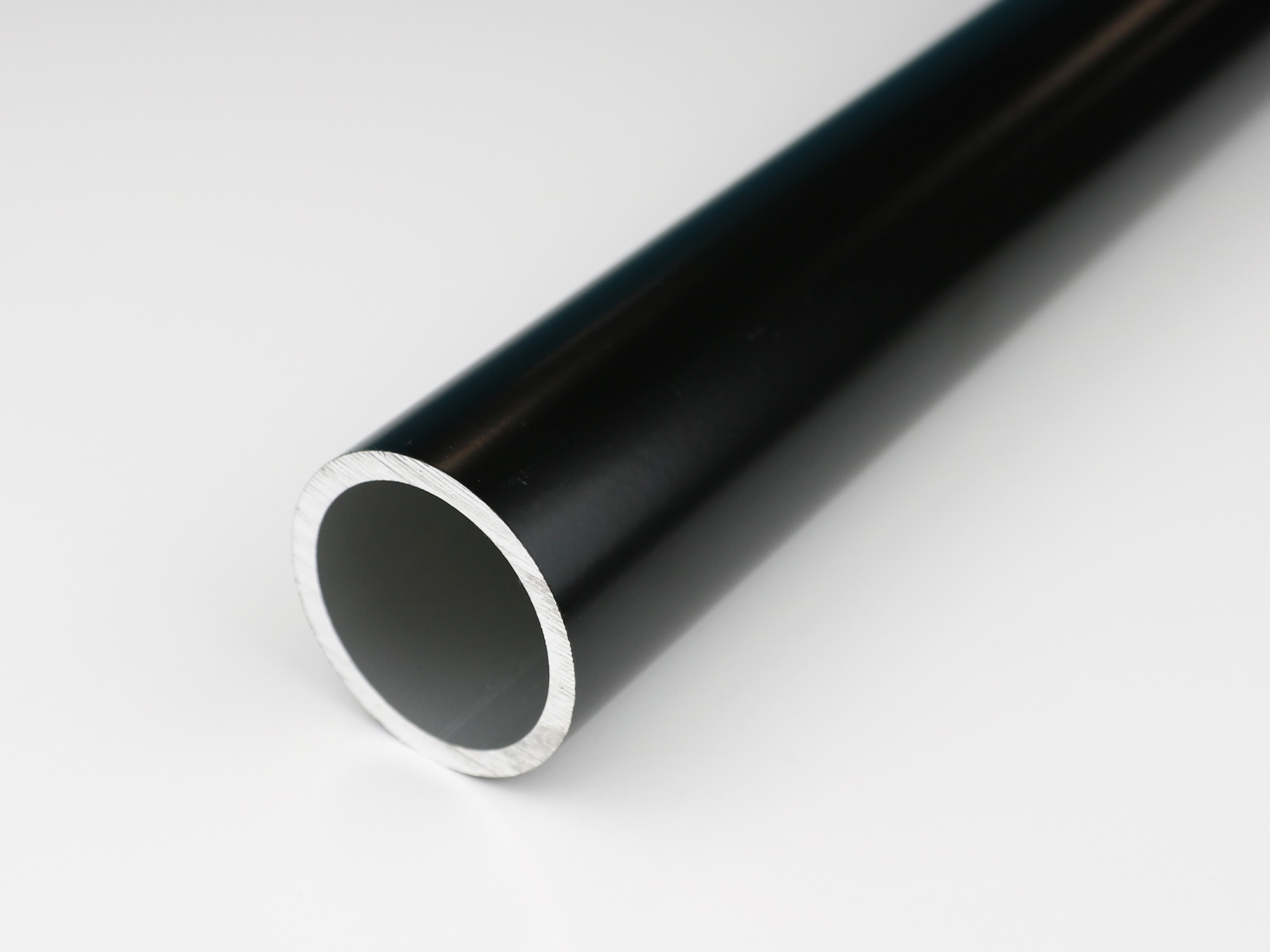

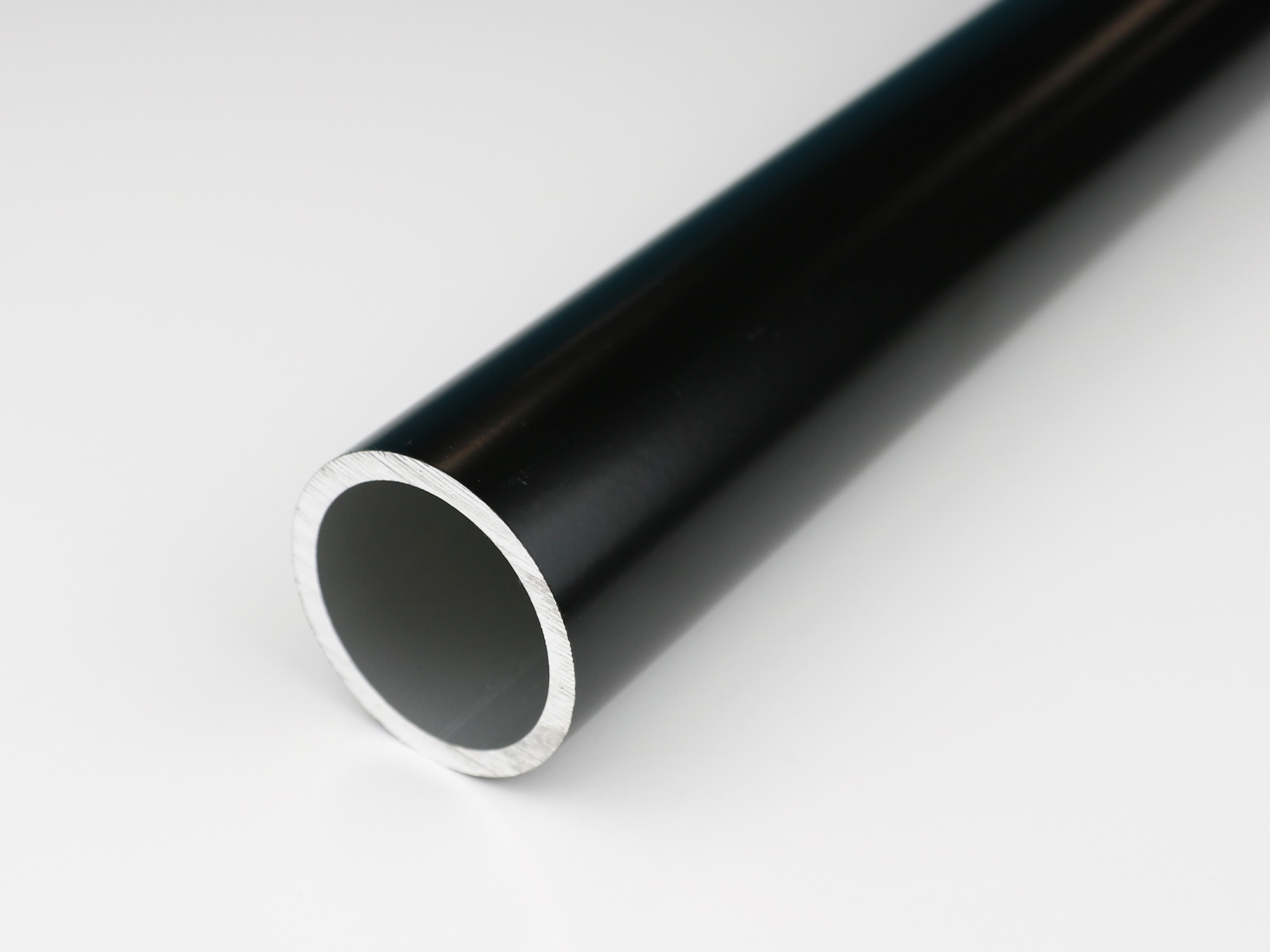

Scaffolding tubes are the backbone of temporary structures on construction sites, providing the essential support and access for workers and materials at height. Among the various types available, the black scaffolding tube is a common sight—often chosen for its affordability and wide availability.

Introduction

Scaffolding is indispensable for safe and efficient construction, renovation, and maintenance. The choice of scaffolding tube directly impacts safety, durability, and long-term costs. Black scaffolding tubes are widely used in many regions, but questions about their rust resistance and surface protection are crucial for project managers, safety inspectors, and contractors.

What Is a Black Scaffolding Tube?

A black scaffolding tube refers to a steel tube that has not received any additional surface treatment after manufacturing. Unlike galvanized or painted tubes, black tubes are essentially “bare” steel, sometimes called “self-finished” or “mill-finished.” They are produced from carbon steel grades such as Q195, Q215, Q235, or S235GT, offering robust structural performance for temporary support and access structures.

Common Specifications:

- Outer diameter: 48.3mm (standard), with some use of 60mm

- Wall thickness: 2.75mm to 4.0mm

- Length: Typically 1–6.5 meters

- Standards: EN39, BS1139, JIS G3444, etc.

Material Properties and Manufacturing

Black scaffolding tubes are made from mild or medium-carbon steel, which provides a balance between strength and workability. The steel is typically hot-rolled, welded, and cut to length. The “black” appearance comes from the oxide layer formed during manufacturing, not from any protective coating.

Key Points:

- No additional surface treatment (e.g., galvanizing or painting) is applied.

- The tubes are strong and suitable for heavy-duty scaffolding systems.

- They are more affordable than galvanized or painted alternatives.

- The oxide layer provides only minimal, temporary protection and is not a substitute for a proper anti-corrosion coating.

Are Black Scaffolding Tubes Rust-Resistant?

No, black scaffolding tubes are not rust-resistant. By definition, black tubes lack any protective coating, making them highly susceptible to rust and corrosion when exposed to moisture, weather, and harsh environments.

- Corrosion Risk: Black tubes will rust more quickly than galvanized or painted tubes, especially in outdoor or humid conditions.

- Surface Rust: Surface rust may appear quickly, especially if the tubes are stored outdoors or exposed to rain.

- Structural Integrity: While minor surface rust is often considered harmless, significant corrosion or pitting can reduce wall thickness and compromise load-bearing capacity.

- Long-Term Exposure: Extended exposure to rain, humidity, or chemicals can accelerate corrosion, leading to the need for frequent replacement or repair.

Surface Treatments and Coatings

Because black scaffolding tubes are not inherently rust-resistant, they are often further treated to improve durability:

1. Painted Scaffolding Tubes

- Black tubes can be painted to add a protective barrier against moisture and corrosion.

- Paint also helps with identification, length marking, and maintenance.

- Regular repainting may be required, especially after heavy use or exposure to harsh conditions.

2. Galvanized Scaffolding Tubes

- Galvanization involves coating black steel tubes with a layer of zinc, usually by hot-dip or pre-galvanizing processes.

- The zinc layer (typically >40 microns for hot-dip) provides strong, long-lasting rust and corrosion resistance.

- Galvanized tubes are the industry standard for outdoor and long-term use.

3. Powder Coating and Oiling

- Some manufacturers offer powder-coated or oiled finishes as additional protection, though these are less common than galvanizing or painting.

- Oiling is a temporary solution, mainly for storage and transport, and must be reapplied regularly.

Comparison: Black vs. Galvanized vs. Painted Scaffolding Tubes

| Feature | Black Scaffolding Tube | Painted Scaffolding Tube | Galvanized Scaffolding Tube |

| Surface Protection | None | Paint layer | Zinc (galvanized) coating |

| Rust Resistance | Low | Moderate (depends on paint quality) | High (best for outdoor use) |

| Cost | Lowest | Moderate | Highest |

| Durability | Prone to rust and corrosion | Improved, but paint may chip | Excellent, long-lasting |

| Common Use | Temporary, indoor, or further treated | Indoor/outdoor, short-medium term | Outdoor, long-term, harsh climates |

| Maintenance | High (requires frequent inspection) | Moderate (repainting needed) | Low (minimal maintenance) |

| Environmental Impact | Higher (due to frequent replacement) | Moderate | Lower (longer service life) |

Applications and Best Practices

Where Are Black Scaffolding Tubes Used?

- Civil and Residential Construction: Often used for temporary supports, formwork, or where cost is a primary concern.

- System Scaffold Manufacturing: Used as base material for making ringlock, cuplock, kwikstage, and other modular systems before further treatment.

- Temporary Structures: Suitable for short-term indoor use or where exposure to moisture is minimal.

- Rental and Reuse: Due to their low cost, black scaffolding tubes are often used in rental fleets for short-duration projects, but require careful inspection between uses.

Best Practices:

- Avoid Prolonged Outdoor Use: Unless painted or galvanized, black scaffolding tubes should not be used for extended outdoor projects.

- Apply Surface Treatment: For longer life and safety, paint or galvanize black tubes before use in corrosive environments.

- Regular Inspection: Check for rust, pitting, and wall thickness loss before each use.

- Combine with Other Materials: For critical or long-term structures, use black tubes only for non-load-bearing elements or combine with galvanized tubes for main supports.

Maintenance and Inspection of Black Scaffolding Tubes

Proper maintenance is crucial for extending the lifespan and ensuring the safety of black scaffolding tubes:

Inspection:

- Look for surface rust, pitting, and structural damage before and after use.

- Use tools like micrometers or depth gauges to measure wall thickness if corrosion is present.

- Replace tubes with significant loss of material or deep pitting.

- Inspect weld seams for cracks or separation, especially after heavy loading.

Cleaning:

- Remove dirt and debris after each use to prevent moisture retention.

- Use a wire brush to remove surface rust and apply rust-inhibiting primer or paint as needed.

Storage:

- Store in a dry, covered area, off the ground, and away from moisture to minimize rust formation.

- Use wooden or plastic spacers to prevent direct contact with wet surfaces.

- For long-term storage, consider light oiling or wrapping in plastic sheeting.

Documentation:

- Keep a maintenance log of inspections and repairs for accountability and compliance.

- Record the age and usage cycles of each tube to track replacement needs.

Black Scaffolding Tube in Modern Construction Projects

Role in Modular Scaffold Systems

- Black scaffolding tubes are often the starting point for manufacturing modular systems like ringlock, cuplock, and kwikstage. These tubes are cut, drilled, and then hot-dip galvanized or painted before final assembly.

Cost-Driven Projects

- In regions or projects where budget constraints are significant, black scaffolding tubes are favored for their low upfront cost, especially for short-term or indoor applications.

Custom Fabrication and Adaptability

- Black tubes are easily cut, welded, and modified for custom scaffolding solutions, making them popular for unique or irregular structures where prefabricated systems may not fit.

Environmental Considerations

- Frequent replacement of rusted black scaffolding tubes can increase waste and environmental impact. Using coated or galvanized tubes, though more expensive initially, reduces long-term waste and resource consumption.

Environmental and Economic Considerations

Economic Factors

- Initial Cost: Black scaffolding tubes are the most economical option for initial purchase.

- Maintenance Costs: Higher due to frequent inspection, cleaning, and potential repainting or replacement.

- Lifecycle Costs: Over time, the need for replacement and repairs may offset the initial savings.

Environmental Impact

- Resource Use: Frequent replacement increases steel consumption and waste.

- Sustainability: Galvanized or painted tubes, with longer service life, are more sustainable for large or long-term projects.

- Recycling: Steel tubes, including black scaffolding tubes, are recyclable, but recycling rusted or heavily corroded tubes may be less efficient.

Conclusion

Black scaffolding tubes are not rust-resistant in their untreated state. They are made from carbon steel without any protective coating, making them vulnerable to rust and corrosion, especially in outdoor or humid environments. For this reason, black tubes are best suited for temporary, indoor, or further processed (painted or galvanized) applications. For long-term durability, safety, and reduced maintenance, galvanized or painted scaffolding tubes are strongly recommended. Regular inspection, cleaning, and proper storage are essential to ensure the safety and longevity of any scaffolding system. While black scaffolding tubes offer cost advantages for short-term or non-critical projects, investing in coated or galvanized tubes is a smarter choice for sustainability and safety in the long run.

FAQ

1. Are black scaffolding tubes rust-resistant by themselves?

No, black scaffolding tubes are not rust-resistant. They lack any protective coating and will rust quickly when exposed to moisture or weather.

2. Can black scaffolding tubes be used outdoors?

They can be used outdoors for very short durations, but are not recommended for long-term outdoor use unless painted or galvanized to prevent rust.

3. How can I protect black scaffolding tubes from rust?

You can paint, oil, or galvanize black tubes to add a protective layer. Painting and galvanizing are the most common methods to enhance rust resistance.

4. What is the difference between black, painted, and galvanized scaffolding tubes?

Black tubes have no coating and rust easily. Painted tubes have a protective paint layer, offering moderate rust resistance. Galvanized tubes are coated with zinc, providing the highest level of rust and corrosion protection.

5. How should black scaffolding tubes be maintained?

Inspect regularly for rust and pitting, clean after use, store in a dry place, and apply paint or primer as needed to prevent corrosion. Keep a maintenance log and replace tubes that show significant wear or thinning.