Content Menu

● What Are Fiberglass Scaffolding Tubes?

● Advantages of Fiberglass Scaffolding Tubes in Industrial Applications

>> 1. Lightweight and Easy to Handle

>> 2. Excellent Corrosion Resistance

>> 3. Non-Conductive and Electrically Safe

>> 4. Resistance to Chemicals and UV Radiation

>> 5. Compliance with Safety Standards

● Comparison: Fiberglass vs. Steel and Aluminum Scaffolding Tubes

● Limitations of Fiberglass Scaffolding Tubes

● Industrial Applications of Fiberglass Scaffolding Tubes

● Maintenance and Longevity

● Safety Considerations When Using Fiberglass Scaffolding Tubes

● Conclusion

● FAQ

>> 1. What makes fiberglass scaffolding tubes safer than steel in electrical environments?

>> 2. How does the weight of fiberglass scaffolding tubes compare to steel and aluminum?

>> 3. Are fiberglass scaffolding tubes resistant to corrosion?

>> 4. Can fiberglass scaffolding tubes support heavy loads like steel scaffolding?

>> 5. Do fiberglass scaffolding tubes require special maintenance?

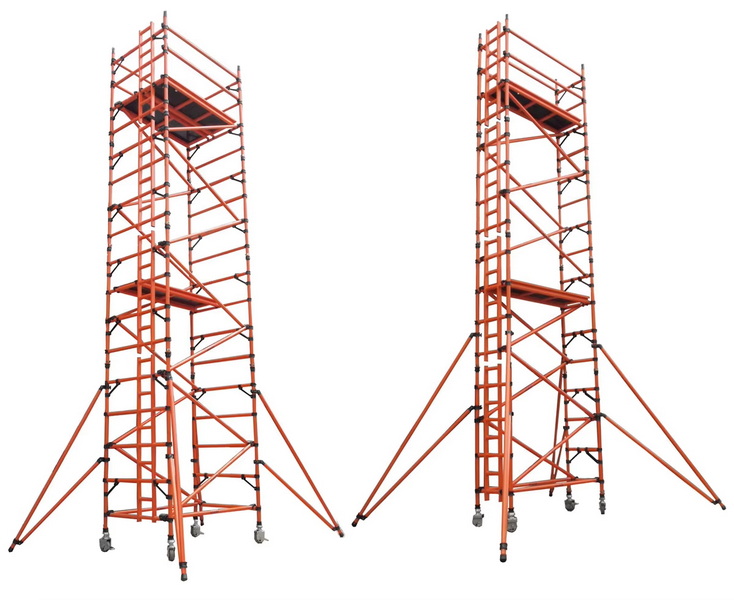

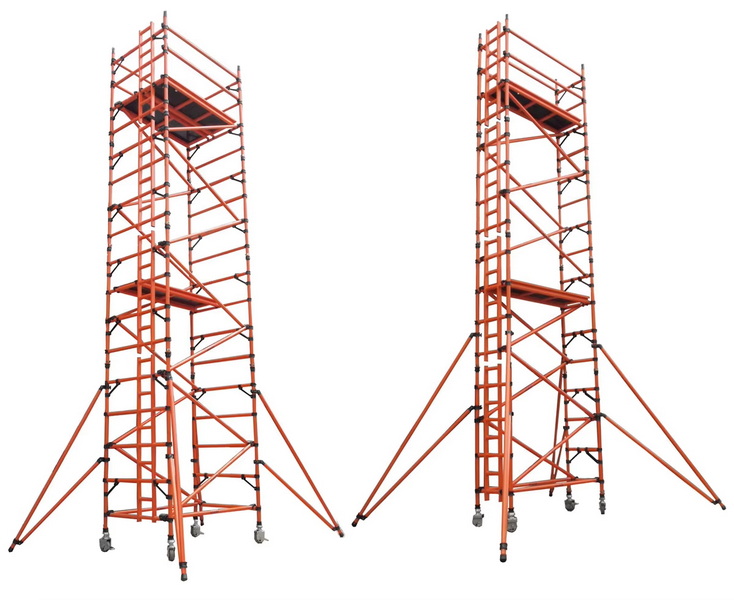

Fiberglass scaffolding tubes, also known as glass-reinforced plastic (GRP) scaffold tubes, have increasingly become a popular alternative to traditional steel and aluminum scaffolding in various industrial settings. This article explores the suitability of fiberglass scaffolding tubes for industrial applications by examining their properties, advantages, limitations, and practical uses.

What Are Fiberglass Scaffolding Tubes?

Fiberglass scaffolding tubes are made from glass fibers embedded in a resin matrix, creating a composite material known as glass-reinforced plastic (GRP). This composition provides a lightweight yet strong structure suitable for scaffolding purposes. Typically, these tubes have an outer diameter of around 48.3 to 48.5 mm and a wall thickness of about 6.65 mm, making them compatible with standard scaffold fittings.

The manufacturing process involves layering continuous glass fibers with resin, which is then cured to form a rigid, durable tube. This process allows for customization in terms of tube diameter, length, and mechanical properties, enabling manufacturers to produce fiberglass scaffolding tubes tailored to specific industrial needs.

Advantages of Fiberglass Scaffolding Tubes in Industrial Applications

1. Lightweight and Easy to Handle

Fiberglass scaffolding tubes weigh significantly less than steel tubes—approximately 1.7 kg per meter compared to steel's 4.5 kg per meter. This reduction in weight makes them easier to transport, assemble, and dismantle, reducing worker fatigue and improving efficiency on-site. The lightweight nature also means that fewer workers are needed for assembly, which can reduce labor costs and speed up project timelines.

2. Excellent Corrosion Resistance

Unlike steel, fiberglass tubes do not rust or corrode, even when exposed to harsh environments such as chemical plants, saltwater, or radiation zones. This corrosion resistance extends the lifespan of scaffolding and reduces maintenance costs, making fiberglass tubes ideal for industrial sites where exposure to corrosive elements is common. The non-corrosive nature also helps maintain structural integrity over time, ensuring safety.

3. Non-Conductive and Electrically Safe

One of the hallmark features of fiberglass scaffolding tubes is their outstanding electrical insulation performance. Being non-conductive, they eliminate the risk of electric shock when working near live electrical equipment or high-voltage areas, thus enhancing worker safety significantly. This property is especially valuable in industries such as electrical utilities, telecommunications, and power generation, where scaffolding often needs to be erected near energized components.

4. Resistance to Chemicals and UV Radiation

Fiberglass tubes are resistant to most chemicals and do not degrade under UV radiation, which is common in outdoor industrial environments. This property ensures that the scaffolding remains structurally sound and safe over long periods, even under exposure to sunlight and chemical agents. The UV resistance also prevents brittleness and discoloration, maintaining the tubes' mechanical properties and appearance.

5. Compliance with Safety Standards

Many fiberglass scaffolding tubes are NASC-approved (National Access and Scaffolding Confederation), ensuring that they meet rigorous safety and quality standards required for industrial use. Compliance with international standards such as EN 12810 and OSHA guidelines also makes fiberglass scaffolding tubes a trusted choice for contractors and safety inspectors.

Comparison: Fiberglass vs. Steel and Aluminum Scaffolding Tubes

| Feature | Fiberglass Scaffolding Tube | Steel Scaffolding Tube | Aluminum Scaffolding Tube |

| Weight | ~1.7 kg/m | ~4.5 kg/m | ~1.56 kg/m |

| Corrosion Resistance | Excellent (non-corrosive) | Poor (requires coatings) | Good (resistant to rust) |

| Electrical Conductivity | Non-conductive (safe near electricity) | Conductive (risk of shock) | Conductive (risk of shock) |

| Load-Bearing Capacity | Moderate (axial strength >300 MPa) | High (up to 79 kN load capacity) | Moderate |

| Maintenance | Low (no painting required) | High (needs regular maintenance) | Moderate |

| Cost | Higher initial cost | Lower initial cost | Moderate |

| Ideal Applications | Electrical sites, chemical plants, radiation zones | Heavy-duty construction | General construction, lightweight needs |

This table highlights that fiberglass scaffolding tubes offer unique advantages in safety and durability in corrosive or electrical environments, while steel remains superior in load-bearing capacity.

Limitations of Fiberglass Scaffolding Tubes

Despite their many benefits, fiberglass scaffolding tubes have some limitations:

- Lower Load-Bearing Capacity: Compared to steel, fiberglass tubes have a lower maximum load capacity, which may limit their use in heavy-duty industrial applications requiring very high strength. For extremely heavy loads, steel scaffolding remains the preferred choice.

- Higher Initial Cost: The upfront cost of fiberglass tubes is generally higher than steel or aluminum scaffolding, though this is often offset by lower maintenance and longer lifespan. Budget-conscious projects may need to weigh initial investment versus long-term savings.

- Potential Surface Damage: Fiberglass can be more susceptible to impact damage or surface abrasion, though the embedded glass fibers provide reinforcement to maintain structural integrity. Care must be taken during handling and installation to avoid cracks or chips.

- Thermal Expansion: Fiberglass has a higher coefficient of thermal expansion compared to steel, which means it can expand or contract more with temperature changes. This requires careful design considerations in environments with extreme temperature variations.

Industrial Applications of Fiberglass Scaffolding Tubes

Fiberglass scaffolding tubes are especially suitable for:

- Electrical and Utility Work: Due to their non-conductive properties, they are ideal for work near live electrical equipment or power lines. This reduces the risk of accidents and allows safer access to energized components.

- Chemical Processing Plants: Their resistance to corrosion from chemicals makes them safer and more durable in such environments. Fiberglass scaffolding tubes can withstand exposure to acids, alkalis, and solvents without degrading.

- Food Industry Sites: Where contamination from rust or metal corrosion must be avoided, fiberglass tubes provide a hygienic alternative. Their smooth surface is easy to clean and does not harbor bacteria.

- Radiation Hazardous Zones: Fiberglass tubes do not conduct electricity or spark, reducing risks in sensitive radiation zones. This is crucial in nuclear plants and laboratories where safety is paramount.

- Offshore and Coastal Construction: Their resistance to saltwater corrosion makes them excellent for marine environments. Fiberglass scaffolding tubes are used on oil rigs, docks, and shipyards where steel scaffolding would rapidly corrode.

- Painting and Coating Facilities: In environments where solvents and paints are used, fiberglass scaffolding tubes resist chemical damage and maintain structural integrity.

Maintenance and Longevity

Fiberglass scaffolding tubes require minimal maintenance beyond routine cleaning. They do not need painting or protective coatings and resist most chemicals and environmental factors. Regular inspections should focus on checking for physical damage or wear, but corrosion-related deterioration is not a concern.

To maximize lifespan:

- Inspect tubes regularly for cracks or surface damage.

- Avoid dropping or striking tubes against hard surfaces.

- Store tubes in a dry, shaded area when not in use.

- Clean tubes with mild detergent and water to remove dirt and chemical residues.

With proper care, fiberglass scaffolding tubes can last 10 to 15 years or more, making them a cost-effective solution over time.

Safety Considerations When Using Fiberglass Scaffolding Tubes

While fiberglass scaffolding tubes offer excellent safety benefits, users should observe the following precautions:

- Avoid Overloading: Always adhere to manufacturer load ratings to prevent structural failure.

- Use Compatible Fittings: Ensure scaffold fittings and couplers are designed or approved for fiberglass tubes to maintain structural integrity.

- Protect Against Impact: Handle tubes carefully to avoid cracks or chips that could compromise strength.

- Training: Workers should be trained on the unique properties of fiberglass scaffolding and safe assembly techniques.

Conclusion

Fiberglass scaffolding tubes are highly suitable for many industrial applications, especially where safety around electricity, corrosion resistance, and lightweight handling are priorities. While they may not replace steel scaffolding in heavy-load scenarios, their unique properties make them indispensable in chemical plants, electrical sites, food industries, and other specialized environments. The initial higher cost is balanced by reduced maintenance, longer lifespan, and enhanced safety, making fiberglass scaffolding tubes a smart investment for industrial projects.

FAQ

1. What makes fiberglass scaffolding tubes safer than steel in electrical environments?

Fiberglass tubes are non-conductive, meaning they do not carry electricity. This property prevents electric shocks when working near live electrical equipment, unlike steel tubes which conduct electricity and pose a risk of electrocution.

2. How does the weight of fiberglass scaffolding tubes compare to steel and aluminum?

Fiberglass tubes weigh about 1.7 kg per meter, which is significantly lighter than steel tubes (~4.5 kg/m) and slightly heavier than aluminum tubes (~1.56 kg/m). This makes fiberglass easier to handle than steel, improving worker safety and efficiency.

3. Are fiberglass scaffolding tubes resistant to corrosion?

Yes, fiberglass tubes do not rust or corrode, even in harsh chemical or marine environments. This resistance extends their service life and reduces maintenance costs compared to steel scaffolding.

4. Can fiberglass scaffolding tubes support heavy loads like steel scaffolding?

Fiberglass tubes have good load-bearing capacity but generally lower than steel. They are suitable for moderate loads but may not be ideal for very heavy-duty applications requiring maximum strength.

5. Do fiberglass scaffolding tubes require special maintenance?

No special maintenance is needed beyond regular cleaning and inspection for physical damage. They do not require painting or protective coatings, unlike steel scaffolding.