Content Menu

● What Are Ringlock Scaffolding Standards?

● Key Features Enabling Compatibility

>> 1. Universal Rosette Design

>> 2. Modular Sizing

>> 3. Regulatory Compliance

● Compatibility With Common Scaffolding Systems

>> 1. Tube-and-Clamp Scaffolding

>> 2. Cuplock Scaffolding

>> 3. Frame Scaffolding

>> 4. Layher Allround®

● Technical Considerations for Hybrid Systems

>> Material Compatibility

>> Load Distribution

>> Joint Integrity

● Challenges and Solutions

● Case Study: Hybrid System in a Power Plant Project

● Industry Feedback on Hybrid Compatibility

● Future Trends in Scaffolding Compatibility

● Maintenance and Safety Protocols for Hybrid Systems

>> Inspection Checklists

>> Training Requirements

● Cost-Benefit Analysis of Hybrid Systems

● Conclusion

● FAQ

>> 1. Can ringlock standards connect to tube-and-clamp scaffolding?

>> 2. Do ringlock systems comply with OSHA standards?

>> 3. Are ringlock ledgers compatible with Cuplock verticals?

>> 4. Can I mix ringlock and frame scaffolding?

>> 5. Does hybridization affect warranty coverage?

Ringlock scaffolding standards form the backbone of one of the most versatile modular scaffolding systems in construction. Their unique design and standardized components raise a critical question: "Can they integrate seamlessly with other scaffolding systems?" This article explores the compatibility of ringlock scaffolding standards with traditional and modern systems, supported by technical insights, visual guides, and real-world applications.

What Are Ringlock Scaffolding Standards?

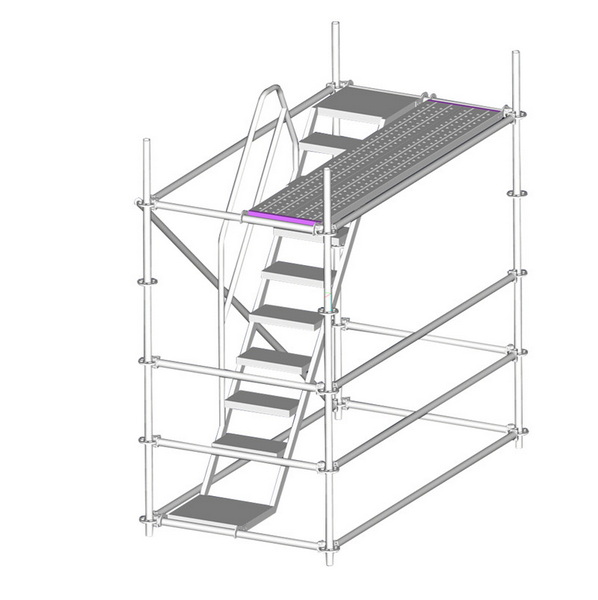

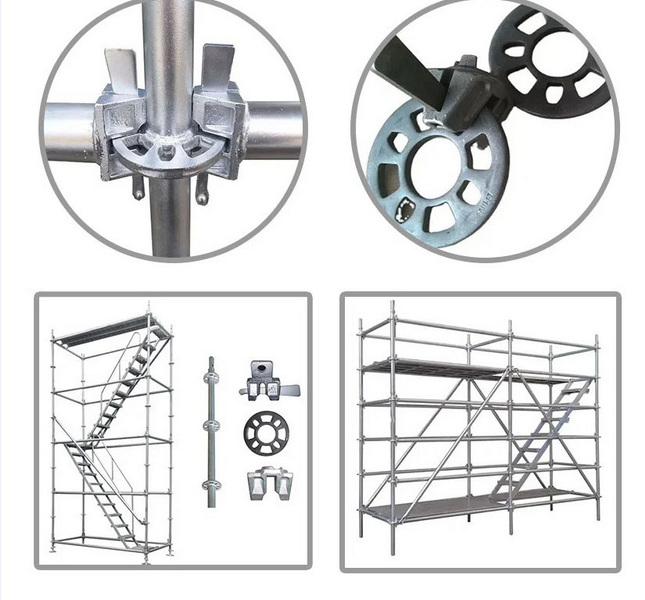

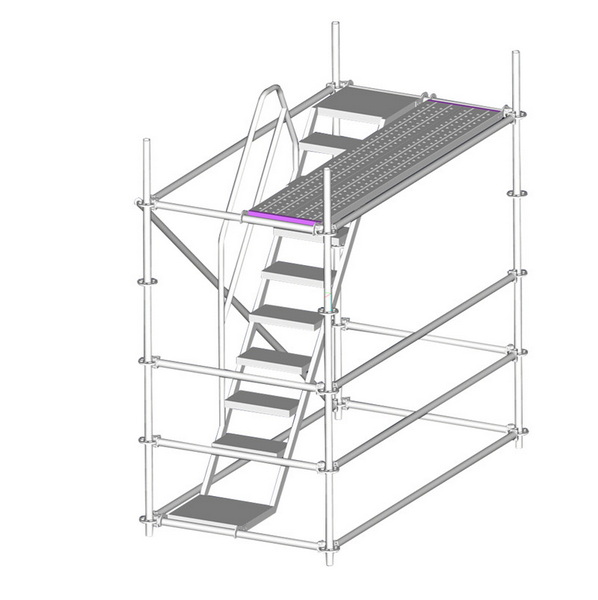

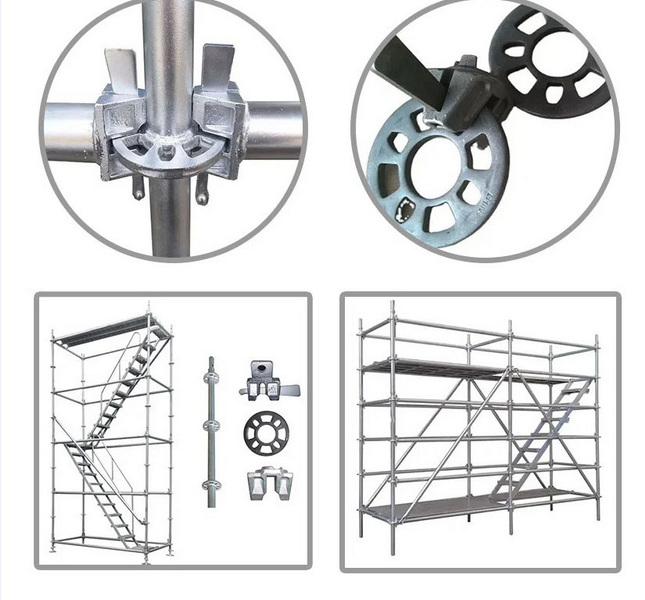

Ringlock scaffolding standards are vertical posts with rosette joints welded at regular intervals (typically 500mm or 1,000mm). These rosettes feature eight holes that allow horizontal ledgers, diagonal braces, and stair stringers to connect at virtually any angle. Made from high-strength steel (Q235 or Q355) and hot-dip galvanized for corrosion resistance, they comply with international standards like EN 12811, ANSI/SSFI SC100-5/05, and AS/NZS 1576.

Key Features Enabling Compatibility

1. Universal Rosette Design

The rosette's eight-hole configuration allows connections with components from other systems, provided they match the 48.3mm or 60.3mm tube diameters. For example:

- Layher Allround®: Ringlock standards can integrate with Layher's rosette-based system using compatible clamps.

- Cuplock Scaffolding: Adapters enable ringlock ledgers to slot into cuplock nodes.

2. Modular Sizing

Standards are available in lengths from 0.5m to 4m, making them adaptable to projects using mixed systems. Adjustable base jacks (up to 600mm) further compensate for height mismatches.

3. Regulatory Compliance

By adhering to EN, ANSI, and AS/NZS standards, ringlock systems meet the same safety and load-bearing criteria as most modern scaffolding, simplifying hybrid setups.

Compatibility With Common Scaffolding Systems

1. Tube-and-Clamp Scaffolding

Ringlock standards can connect to traditional tube-and-clamp systems using rosette-to-clamp adapters. However, this requires manual adjustment and may reduce load capacity.

2. Cuplock Scaffolding

Specialized ledger adapters allow ringlock horizontals to lock into cuplock verticals, though load capacity may drop by 20–30%.

3. Frame Scaffolding

Ringlock standards are incompatible with welded frame systems due to fixed node spacing. Hybrid setups require independent structures linked via platforms.

4. Layher Allround®

The Layher system's rosette design closely mirrors ringlock, enabling direct compatibility for ledgers and braces without adapters.

Technical Considerations for Hybrid Systems

Material Compatibility

Ringlock standards are typically made from high-grade steel with a yield strength of 235–355 MPa. When integrating with aluminum systems (e.g., Kwikstage), thermal expansion differences must be factored into load calculations.

Load Distribution

Hybrid systems require careful planning to avoid overloading weaker components. For example:

- Ringlock + Tube-and-Clamp: Limit loads to 70% of the tube-and-clamp system's capacity.

- Ringlock + Cuplock: Use diagonal bracing to redistribute stress.

Joint Integrity

Third-party adapters must meet ISO 1461 standards for galvanization and tensile strength. Regular torque checks (e.g., 50 Nm for wedge locks) ensure connections remain secure.

Challenges and Solutions

| Challenge | Solution |

| Mismatched tube diameters | Use reducer sleeves or forged adapters. |

| Differing load capacities | Limit hybrid sections to 70% of the weaker system’s rated capacity. |

| Regulatory discrepancies | Consult local safety guidelines (e.g., OSHA, EN 12811) during planning. |

| Connector incompatibility | Source third-party universal clamps or custom brackets. |

Case Study: Hybrid System in a Power Plant Project

A 2024 U.S. energy project combined ringlock standards with Cuplock scaffolding to navigate tight spaces and heavy loads:

- Ringlock Components: Vertical standards (60.3mm) provided stability for 12-ton compressor installations.

- Cuplock Components: Horizontal ledgers created access pathways in confined areas.

- Adapters: Forged steel connectors bridged the systems, maintaining 80% of ringlock's load capacity.

“The hybrid design cut assembly time by 35% and reduced material costs by $18,000.” – Site Manager, DSS Construction

Industry Feedback on Hybrid Compatibility

A 2025 survey of 200 construction firms revealed:

- 72% successfully integrated ringlock with at least one other system.

- Top Benefits: Cost savings (58%), flexibility (49%), reduced downtime (34%).

- Key Concerns: Training gaps (41%), adapter availability (29%).

Future Trends in Scaffolding Compatibility

1. Smart Adapters: RFID-tagged connectors that auto-calculate load limits in hybrid setups.

2. 3D-Printed Joints: Custom rosette adapters printed onsite for legacy systems.

3. Global Standardization: Efforts by ISO to unify rosette dimensions across brands.

Maintenance and Safety Protocols for Hybrid Systems

Inspection Checklists

- Verify adapter certifications (e.g., TÜV, CE marks).

- Check for corrosion at joint interfaces.

- Test load distribution with strain gauges.

Training Requirements

Workers must complete hybrid-specific courses covering:

- Adapter installation techniques.

- Load limit calculations.

- Emergency disassembly procedures.

Cost-Benefit Analysis of Hybrid Systems

| Factor | Ringlock-Only | Hybrid System |

| Initial Cost | $12,000 | $8,500 (+$1,200 for adapters) |

| Assembly Time | 40 hours | 28 hours |

| Longevity | 15 years | 10–12 years |

| Versatility | Moderate | High |

Note: Figures based on a 100m² scaffolding setup.

Conclusion

Ringlock scaffolding standards offer broad compatibility with modern systems like Layher and Cuplock through adaptable rosette joints and standardized sizing. While challenges like load mismatches persist, innovations in adapters and regulatory alignment are bridging gaps. For projects requiring mixed systems, ringlock's modularity and compliance make it a future-proof choice. Hybrid setups unlock cost savings and flexibility but demand rigorous training and maintenance to ensure safety.

FAQ

1. Can ringlock standards connect to tube-and-clamp scaffolding?

Yes, using rosette-to-clamp adapters, though load capacity may decrease by 25–40% depending on joint configuration.

2. Do ringlock systems comply with OSHA standards?

Yes, when installed per manufacturer guidelines, they meet OSHA 1926.451 for scaffold safety.

3. Are ringlock ledgers compatible with Cuplock verticals?

Only with forged adapters, which typically reduce maximum load to 2.5 kN/m².

4. Can I mix ringlock and frame scaffolding?

No-frame systems lack rosette joints, requiring separate structures linked via platforms.

5. Does hybridization affect warranty coverage?

Most manufacturers void warranties if non-certified adapters are used. Always consult suppliers first.