Content Menu

● What Are Beam Scaffolding Couplers?

● Understanding Aluminum Scaffolding

● Compatibility of Beam Couplers with Aluminum Scaffolding

>> Material Considerations

>> Mechanical Compatibility

>> Industry Standards

● Advantages of Using Beam Couplers with Aluminum Scaffolding

● Challenges and Considerations

>> Galvanic Corrosion

>> Load Distribution

>> Proper Installation

>> Environmental Factors

● Types of Beam Scaffolding Couplers

● How to Use Beam Couplers with Aluminum Scaffolding: Step-by-Step Guide

>> 1. Preparation

>> 2. Positioning

>> 3. Installation

>> 4. Inspection

>> 5. Ongoing Maintenance

● Common Applications for Beam Couplers with Aluminum Scaffolding

● Safety and Regulatory Compliance

● Innovations and Future Trends in Beam Couplers and Aluminum Scaffolding

>> Lighter, Stronger Materials

>> Improved Corrosion Resistance

>> Smart Scaffolding

>> Modular Systems

● Case Study: Beam Couplers in High-Rise Construction

● Environmental and Economic Benefits

● Conclusion

● FAQ

>> 1. Can I use steel beam couplers with aluminum scaffold tubes?

>> 2. Are beam couplers compatible with all types of aluminum scaffolding?

>> 3. What is the maximum load a beam coupler can handle in aluminum scaffolding?

>> 4. How can I prevent corrosion when using steel couplers with aluminum tubes?

>> 5. Are beam scaffolding couplers reusable?

Aluminum scaffolding has become a staple in modern construction due to its lightweight, high strength, and corrosion resistance. As with any scaffolding system, secure connections between components are essential for safety and structural integrity. This brings us to a critical question: Can beam couplers be used with aluminum scaffolding? This comprehensive guide explores the compatibility, advantages, challenges, and best practices for using beam scaffolding couplers with aluminum scaffolding systems.

What Are Beam Scaffolding Couplers?

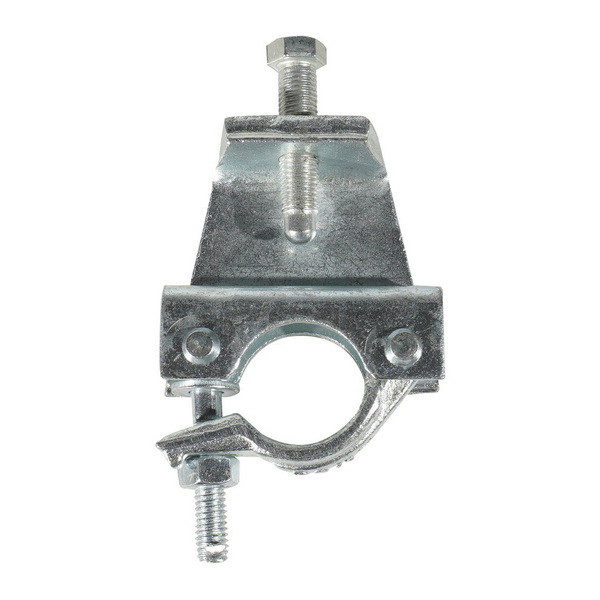

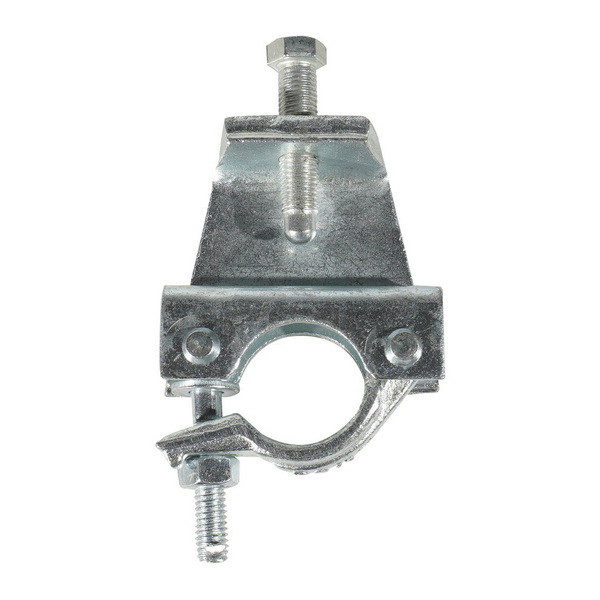

Beam scaffolding couplers—also known as beam clamps, girder couplers, or gravlock couplers—are specialized fittings designed to connect scaffold tubes to structural beams or girders. They play a vital role in securing scaffolding to existing structures, providing anchoring points, and enabling safe load transfer between scaffolding and building frameworks.

- Designed for use with I-beams or girders (up to 45mm flange thickness)

- Provide immense grip and exceed slip requirements of BS 1139

- Must be used in pairs for maximum safety and stability

Understanding Aluminum Scaffolding

Aluminum scaffolding is favored for its:

- Lightweight construction (less than half the weight of steel)

- High strength-to-weight ratio (often 1.5 times stronger than steel by weight)

- Excellent corrosion resistance

- Ease of assembly and transport

- Temporary platforms

- Suspended scaffolds

- Bridging and cantilever solutions

- Formwork support

Aluminum beams and tubes are typically manufactured to standard dimensions (e.g., 48.3mm outer diameter), ensuring compatibility with standard scaffolding fittings.

Compatibility of Beam Couplers with Aluminum Scaffolding

Material Considerations

Beam couplers are generally made from high-strength steel, hot-dip galvanized for corrosion resistance. Aluminum scaffolding components are, as the name suggests, made from high-grade aluminum alloys. The key compatibility factors include:

- Diameter Matching: Most beam couplers are designed for 48.3mm tubes, which matches the standard size for aluminum scaffold tubes.

- Strength and Load Capacity: Steel couplers provide robust connections, suitable for both steel and aluminum tubes as long as load limits are not exceeded.

- Corrosion Considerations: While aluminum is naturally corrosion resistant, using steel couplers on aluminum tubes can introduce the risk of galvanic corrosion if exposed to moisture. This can be mitigated by using couplers with protective coatings or isolating materials.

Mechanical Compatibility

- Secure Clamping: Beam couplers are engineered to grip tightly onto both steel and aluminum tubes, provided the outer diameter matches.

- Load Transfer: The load-bearing capacity of the connection is determined by the coupler's strength and the tube's material properties. Aluminum tubes, though strong, may have lower point-load resistance compared to steel, so load calculations are essential.

Industry Standards

Beam couplers and aluminum scaffolding components are manufactured to international standards such as BS 1139 and EN 74, ensuring interoperability and safety.

Advantages of Using Beam Couplers with Aluminum Scaffolding

- Versatility: Beam couplers allow aluminum scaffolding to be securely anchored to existing steel beams, concrete structures, or other fixed elements.

- Lightweight Assembly: The combination of lightweight aluminum tubes and strong steel couplers makes for easier handling and faster assembly/disassembly.

- Enhanced Safety: Properly installed beam couplers provide a stable connection, reducing the risk of scaffold movement or collapse.

- Compliance: When used according to manufacturer guidelines and standards, the system meets or exceeds safety regulations.

- Adaptability: Aluminum scaffolding with beam couplers can be used in a wide variety of environments, from industrial sites to commercial buildings, and even in challenging outdoor conditions.

Challenges and Considerations

Galvanic Corrosion

When steel couplers are used with aluminum tubes, there is a risk of galvanic corrosion, especially in moist environments. This can be minimized by:

- Using galvanized or coated couplers

- Applying isolating washers or sleeves between the coupler and the tube

- Regular inspection and maintenance

Load Distribution

Aluminum, while strong, is not as ductile as steel. Concentrated loads from couplers can deform or damage aluminum tubes if not properly distributed. Always ensure:

- The load does not exceed the rated capacity of the aluminum tube or the coupler

- Use of spreader plates or sleeves if necessary to distribute load

Proper Installation

- Beam couplers must be tightened to the manufacturer's specified torque

- Always use couplers in pairs for beam connections

- Regularly inspect for wear, deformation, or corrosion

Environmental Factors

- Temperature Fluctuations: Aluminum expands and contracts more with temperature changes than steel, so periodic checks for tightness are recommended.

- Exposure to Chemicals: Construction sites may expose scaffolding to chemicals or salt spray, which can accelerate corrosion. Choosing the right protective coatings for couplers is essential.

Types of Beam Scaffolding Couplers

| Coupler Type | Application | Material | Typical Use Case |

| Girder/Beam Coupler | Connects tube to beam/girder flange | Forged Steel | Anchoring scaffold to I-beam |

| Swivel Coupler | Connects tubes at any angle | Steel/Alum | Diagonal bracing |

| Double Coupler | Connects tubes at 90° | Steel/Alum | Main scaffold joints |

| Sleeve Coupler | Joins tubes end-to-end | Steel/Alum | Extending tubes |

| Universal Clamp | Fixes aluminum beams to formwork/walers | Steel | Formwork support |

How to Use Beam Couplers with Aluminum Scaffolding: Step-by-Step Guide

1. Preparation

- Inspect all components for damage or corrosion

- Ensure tube diameters match (typically 48.3mm)

- Gather necessary tools (wrenches, torque tools, isolators)

2. Positioning

- Place the aluminum scaffold tube against the beam or girder

- Align the beam coupler jaws over the flange of the beam

3. Installation

- Attach the coupler around the tube and beam flange

- Tighten bolts to the specified torque

- Repeat on the opposite side to use couplers in pairs

4. Inspection

- Check for secure fit and proper alignment

- Ensure no visible gaps or slippage

- Confirm load path and bracing as per design

5. Ongoing Maintenance

- Inspect regularly for signs of wear or corrosion

- Retighten bolts as necessary

- Replace any damaged components immediately

Common Applications for Beam Couplers with Aluminum Scaffolding

- Suspended Platforms: Securely attaching aluminum scaffold platforms to overhead beams for maintenance or construction.

- Temporary Roofs: Creating stable anchor points for temporary weather protection structures.

- Bridging Gaps: Spanning large distances by connecting aluminum beams to fixed steel structures.

- Formwork Support: Using universal clamps to fix aluminum beams to formwork walers for concrete work.

- Facade Work: Attaching scaffolding to building facades or structural elements for window installation, painting, or repairs.

Safety and Regulatory Compliance

- Always use couplers and tubes that comply with recognized standards (BS 1139, EN 74).

- Train workers in correct assembly and inspection procedures.

- Regularly inspect all connections and replace worn or corroded parts.

- Do not exceed rated load capacities for either couplers or aluminum tubes.

- Ensure that all beam scaffolding coupler installations are supervised by a competent person.

Innovations and Future Trends in Beam Couplers and Aluminum Scaffolding

Lighter, Stronger Materials

With advances in metallurgy and composite materials, manufacturers are developing even lighter and stronger beam couplers. Some couplers now incorporate high-strength aluminum alloys or hybrid designs to reduce weight without compromising safety.

Improved Corrosion Resistance

Modern coatings and surface treatments for beam scaffolding couplers further minimize the risk of galvanic corrosion when used with aluminum tubes. Some innovative designs include built-in isolators or non-metallic inserts.

Smart Scaffolding

Digital monitoring systems are being developed to track the condition of scaffolding components, including couplers. These systems can alert site managers to potential issues like loosening or corrosion, enhancing safety and reducing downtime.

Modular Systems

Aluminum scaffolding is increasingly modular, with quick-connect couplers that speed up assembly and improve adaptability on complex sites. These systems often integrate beam couplers as standard components, ensuring compatibility and ease of use.

Case Study: Beam Couplers in High-Rise Construction

In a recent high-rise renovation project, a construction firm used aluminum scaffolding with beam scaffolding couplers to create suspended work platforms attached to the building's steel framework. The combination allowed for rapid assembly at height, reduced manual handling risks, and ensured secure anchorage even in challenging weather conditions. Regular inspections and the use of galvanized, high-strength couplers prevented corrosion and maintained structural integrity throughout the project.

Environmental and Economic Benefits

- Reduced Carbon Footprint: Aluminum scaffolding is recyclable and lighter, reducing transportation emissions.

- Lower Labor Costs: Easier handling and faster assembly translate to lower labor costs and improved project timelines.

- Longer Lifespan: With proper maintenance, both aluminum scaffolding and quality beam couplers have a long service life, offering excellent return on investment.

Conclusion

Beam couplers can be safely and effectively used with aluminum scaffolding, provided that the components are compatible in size, properly installed, and maintained. The combination offers the benefits of lightweight assembly, robust load-bearing capacity, and versatile application across a wide range of construction scenarios. However, attention must be paid to potential issues such as galvanic corrosion and load distribution. By following best practices and adhering to industry standards, construction professionals can maximize both the safety and efficiency of their scaffolding systems.

FAQ

1. Can I use steel beam couplers with aluminum scaffold tubes?

Yes, steel beam couplers can be used with aluminum scaffold tubes as long as the tube diameter matches (typically 48.3mm) and precautions are taken to prevent galvanic corrosion, such as using galvanized couplers or isolating materials.

2. Are beam couplers compatible with all types of aluminum scaffolding?

Most beam couplers are compatible with standard aluminum scaffolding tubes, especially those with a 48.3mm outer diameter. Always check manufacturer specifications for compatibility.

3. What is the maximum load a beam coupler can handle in aluminum scaffolding?

The load capacity depends on the coupler design and installation. For example, girder couplers can handle up to 30 kN per pair in vertical load, but the limiting factor may be the strength of the aluminum tube itself. Always refer to both coupler and tube load ratings.

4. How can I prevent corrosion when using steel couplers with aluminum tubes?

Use hot-dip galvanized or coated couplers, and consider using isolating sleeves or washers between the steel and aluminum to minimize galvanic corrosion.

5. Are beam scaffolding couplers reusable?

Yes, beam scaffolding couplers are typically made from durable materials like steel and are designed for repeated use, provided they are regularly inspected and maintained.