Content Menu

● What is Ladder Clamp Scaffolding?

● Benefits of Reusing Ladder Clamp Scaffolding

>> Cost Efficiency

>> Environmental Sustainability

>> Enhanced Safety

● Applications of Ladder Clamp Scaffolding

● Choosing the Right Ladder Clamp Scaffolding

● Maintenance and Storage

● Best Practices for Reusing Scaffolding

● Innovations in Scaffolding Technology

● Regulatory Compliance

● Case Studies

● Conclusion

● FAQ

>> 1. What Materials Are Ladder Clamps Made Of?

>> 2. Can Different Types of Scaffolding Couplers Be Used Together?

>> 3. How Do You Attach a Ladder Clamp?

>> 4. Are Scaffolding Components Reusable?

>> 5. What Are the Key Benefits of Using Ladder Clamp Scaffolding?

● Citations:

Ladder clamp scaffolding is a versatile and essential tool in various industries, including construction, maintenance, and telecommunications. It provides a safe and stable platform for workers to perform tasks at heights. One of the key benefits of ladder clamp scaffolding is its reusability, which can significantly reduce costs and environmental impact by minimizing waste. In this article, we will explore the concept of reusing ladder clamp scaffolding for multiple jobs, its benefits, and how it contributes to sustainable practices in the construction and maintenance sectors.

What is Ladder Clamp Scaffolding?

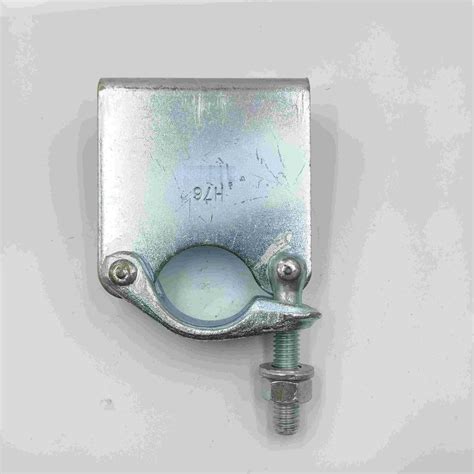

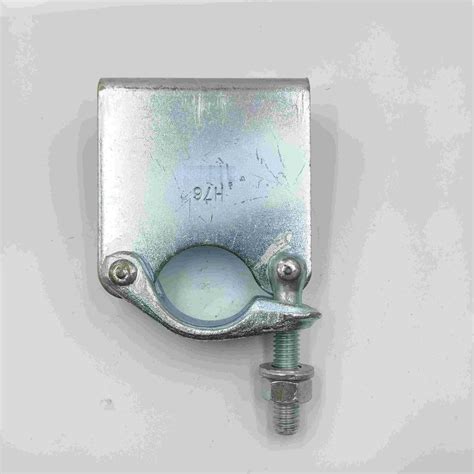

Ladder clamp scaffolding involves using ladder clamps to secure ladders to scaffolding structures. These clamps are designed to be adjustable and can accommodate different ladder sizes, making them highly versatile for various applications. They are typically made from durable materials like steel or aluminum, ensuring long-term use with minimal maintenance.

Benefits of Reusing Ladder Clamp Scaffolding

Cost Efficiency

Reusing ladder clamp scaffolding can significantly reduce costs associated with purchasing new equipment for each project. By maintaining and properly storing the scaffolding components, they can be easily assembled and disassembled for different jobs, extending their lifespan. This approach is particularly beneficial for small to medium-sized businesses that may not have the budget for frequent equipment purchases.

Environmental Sustainability

The reusability of ladder clamp scaffolding contributes to environmental sustainability by reducing waste. Scaffolding components are designed to be modular and adjustable, allowing them to be reconfigured for various projects. This approach minimizes the need for new materials, thereby reducing the environmental impact of construction and maintenance activities. Additionally, reusing scaffolding reduces the energy required for manufacturing new components, which further decreases carbon emissions.

Enhanced Safety

Reusing scaffolding components ensures that they are well-tested and reliable, which is crucial for maintaining safety standards. Properly maintained scaffolding reduces the risk of accidents, providing workers with a secure working environment. Regular inspections and maintenance can identify any potential issues before they become safety hazards.

Applications of Ladder Clamp Scaffolding

Ladder clamp scaffolding is widely used in various industries, including:

- Construction Sites: Ensuring ladders are securely attached to scaffolding for workers at height. This is particularly important during building construction, renovation, or demolition projects.

- Telecommunications: Stabilizing ladders when working on power poles or cell towers. This ensures that technicians can safely perform maintenance or repairs on communication infrastructure.

- Window Cleaning: Keeping ladders in place during window cleaning at high elevations. This is essential for ensuring the safety of window cleaners working on tall buildings.

- Maintenance and Repairs: Used in industries like HVAC, electrical work, and plumbing for inspections or repairs at height. Ladder clamp scaffolding provides a stable platform for technicians to access hard-to-reach areas.

Choosing the Right Ladder Clamp Scaffolding

When selecting ladder clamp scaffolding for reuse, consider the following factors:

- Type of Ladder: Ensure the clamp is compatible with the ladder type. Different ladders may require specific clamp designs to ensure a secure fit.

- Working Environment: Consider the conditions under which the scaffolding will be used. For example, in harsh weather conditions, additional support or protection may be needed.

- Load Capacity: Choose clamps that can support the intended load. This includes the weight of workers, tools, and any additional equipment.

- Ease of Use: Opt for clamps that are easy to set up and adjust. This can save time and reduce labor costs during setup and teardown.

Maintenance and Storage

Proper maintenance and storage are crucial for extending the lifespan of ladder clamp scaffolding. Regularly inspect the components for damage and store them in a dry, secure location to prevent corrosion or damage. Cleaning the components after each use can also help maintain their condition.

Best Practices for Reusing Scaffolding

To maximize the reusability of ladder clamp scaffolding, follow these best practices:

- Regular Inspections: Conduct thorough inspections before and after each use to identify any damage or wear.

- Proper Storage: Store scaffolding components in a dry, secure area to prevent damage from weather or pests.

- Training: Ensure that all personnel are trained in the safe assembly, use, and disassembly of scaffolding.

- Documentation: Keep records of maintenance and inspections to track the condition and history of the scaffolding.

Innovations in Scaffolding Technology

Recent innovations in scaffolding technology have improved the efficiency and safety of ladder clamp scaffolding. For example, modular scaffolding systems allow for quicker setup and teardown, reducing labor costs. Additionally, advanced materials and designs have increased the durability and versatility of scaffolding components.

Regulatory Compliance

Ensure that all scaffolding meets local and national safety standards. Compliance with regulations such as OSHA in the United States or HSE in the UK is essential for avoiding fines and ensuring worker safety.

Case Studies

Several companies have successfully implemented reusable ladder clamp scaffolding systems, resulting in significant cost savings and improved safety records. For instance, a construction company in Europe reported a 30% reduction in scaffolding-related costs by adopting a reusable scaffolding strategy.

Conclusion

Ladder clamp scaffolding is a valuable asset in various industries due to its reusability, cost efficiency, and contribution to environmental sustainability. By properly maintaining and storing these components, they can be reused for multiple jobs, ensuring a safe and efficient working environment. As technology continues to evolve, we can expect even more innovative solutions that enhance the durability and versatility of scaffolding systems.

FAQ

1. What Materials Are Ladder Clamps Made Of?

Ladder clamps are commonly made from durable materials such as steel or aluminum, which are resistant to wear and tear.

2. Can Different Types of Scaffolding Couplers Be Used Together?

Yes, different types of scaffolding couplers can be used together, depending on the specific requirements of the scaffolding structure.

3. How Do You Attach a Ladder Clamp?

To attach a ladder clamp, position it over the ladder rung and secure it to the structure by tightening the clamp using its built-in mechanism.

4. Are Scaffolding Components Reusable?

Yes, scaffolding components, including couplers, are designed to be reusable. They are made from durable materials like steel or aluminum, which can withstand repeated use.

5. What Are the Key Benefits of Using Ladder Clamp Scaffolding?

The key benefits include increased safety, cost efficiency, and environmental sustainability. Ladder clamp scaffolding provides a stable working platform, reduces the need for new materials, and minimizes waste.

Citations:

[1] https://www.affixksa.com/what-is-a-ladder-clamp-and-how-does-it-work/

[2] https://www.youtube.com/watch?v=ZM6Tlh_NAnQ

[3] https://patents.google.com/patent/WO2023071385A1/zh

[4] https://dss.net/sustainable-scaffolding/

[5] https://www.alamy.com/stock-photo/scaffolding-clamp.html

[6] https://www.bbc.com/learningenglish/chinese/features/q-and-a/ep-200318

[7] https://grsscaffolding.com/blog/scaffolding-couplers-types/

[8] https://www.shutterstock.com/video/search/ladder-on-scaffolding

[9] https://www.sohu.com/a/229746319_498025

[10] https://patents.google.com/patent/WO2019144468A1/zh