Content Menu

● Introduction to Liba Steel Build Frames Scaffolding System Solutions

● Why Customization Matters in Scaffolding Systems

>> Adapting to Complex Project Requirements

>> Improving Efficiency and Safety

● How Liba Steel Build Frames Scaffolding System Solutions Can Be Customized

>> 1. Modular Components for Flexible Configurations

>> 2. Custom Sizes and Dimensions

>> 3. Special Accessories and Components

>> 4. Integration with Other Systems

● Case Studies: Successful Customization of Liba Steel Build Frames Scaffolding System Solutions

>> Case Study 1: High-Rise Building with Irregular Geometry

>> Case Study 2: Industrial Plant Maintenance in Hazardous Zones

>> Case Study 3: Event Staging with Unique Load Requirements

● Advantages of Choosing Customized Liba Steel Build Frames Scaffolding System Solutions

● How to Request Custom Liba Steel Build Frames Scaffolding System Solutions

>> Step 1: Define Project Requirements

>> Step 2: Consult with Liba Experts

>> Step 3: Review and Approve Design

>> Step 4: Manufacturing and Delivery

>> Step 5: On-Site Assembly and Support

● Maintenance and Longevity of Customized Liba Steel Build Frames Scaffolding System Solutions

● Innovations Driving Customization in Liba Steel Build Frames Scaffolding System Solutions

● Conclusion

● FAQ

>> 1. Can Liba steel build frames scaffolding system solutions be customized for any project size?

>> 2. How does customization affect the delivery time of Liba scaffolding products?

>> 3. Are customized Liba scaffolding systems compliant with safety standards?

>> 4. Can Liba scaffolding be customized for hazardous environments?

>> 5. Does Liba provide technical support for custom scaffolding assembly?

In the fast-evolving construction industry, flexibility and adaptability are crucial. Projects often present unique challenges that require tailored scaffolding solutions to ensure safety, efficiency, and cost-effectiveness. The Liba steel build frames scaffolding system solutions have gained a strong reputation for their ability to be customized to meet diverse project requirements. This article delves into the customization capabilities of Liba steel frame systems, showcasing how these solutions can be adapted for unique construction needs.

Introduction to Liba Steel Build Frames Scaffolding System Solutions

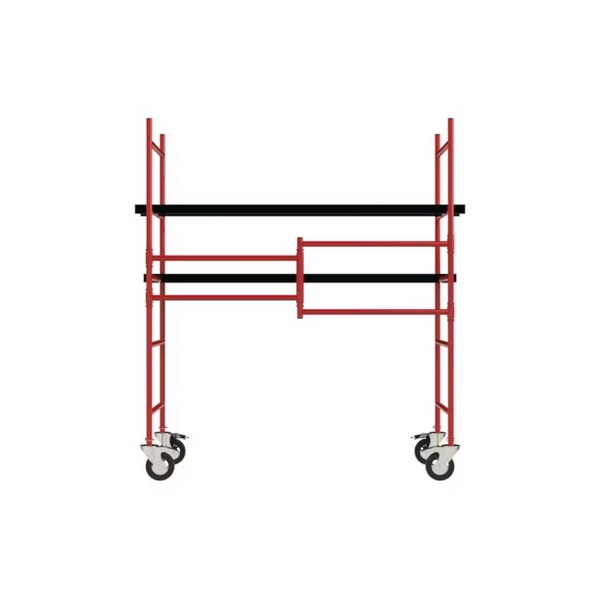

Liba is a globally recognized manufacturer specializing in steel scaffolding systems, including steel build frames, construction hoists, mast climbers, and suspended scaffolds. Their Liba steel build frames scaffolding system solutions are designed with modularity and precision engineering, allowing for extensive customization to fit various project demands.

Customization is a vital feature because no two construction projects are identical. Whether working on irregular building shapes, complex architectural designs, or challenging environments, Liba's systems can be tailored to provide optimal scaffolding solutions.

Why Customization Matters in Scaffolding Systems

Adapting to Complex Project Requirements

Construction projects often involve unique architectural features such as curved facades, inclined surfaces, or limited space. Standard scaffolding may not fit these scenarios efficiently. Custom scaffolding solutions enable:

- Precise fit to irregular shapes

- Optimized use of space in congested sites

- Enhanced safety by ensuring structural integrity tailored to the project

Improving Efficiency and Safety

Customized scaffolding reduces the need for on-site modifications, which can be time-consuming and risky. Pre-engineered solutions from Liba ensure:

- Faster assembly and disassembly

- Reduced labor costs

- Minimized risk of structural failure or accidents

How Liba Steel Build Frames Scaffolding System Solutions Can Be Customized

1. Modular Components for Flexible Configurations

Liba's scaffolding frames are composed of standardized modular components such as vertical standards, ledgers, transoms, and diagonal braces. These parts can be combined in various ways to create scaffolding structures that fit specific height, width, and load requirements.

2. Custom Sizes and Dimensions

Liba offers customization of frame sizes to accommodate unique project dimensions. For example, vertical standards can range from 0.5m to 4.0m or more, and ledgers can be tailored to fit unusual widths or lengths. This flexibility is critical for projects with non-standard measurements.

3. Special Accessories and Components

Additional components such as adjustable base jacks, guardrails, steel planks with anti-slip surfaces, and specialized clamps can be included based on project needs. Liba also provides fire-resistant steel boards suitable for hazardous environments like oil & gas facilities.

4. Integration with Other Systems

Liba scaffolding systems can be integrated with construction hoists, mast climbers, and suspended scaffolds to provide comprehensive access solutions for complex projects. This integration can be customized to streamline workflow and enhance site safety.

Case Studies: Successful Customization of Liba Steel Build Frames Scaffolding System Solutions

Case Study 1: High-Rise Building with Irregular Geometry

A skyscraper project required scaffolding to follow an inclined and curved exterior. Liba's engineers designed custom frame sizes and special swivel clamps to accommodate the angles, ensuring a secure and stable structure that met all safety standards.

Case Study 2: Industrial Plant Maintenance in Hazardous Zones

For maintenance in a chemical plant, Liba provided fire-resistant steel boards and corrosion-resistant galvanized frames customized to fit tight spaces and comply with strict safety regulations.

Case Study 3: Event Staging with Unique Load Requirements

An outdoor event required scaffolding platforms to support heavy equipment and lighting rigs. Liba customized the scaffolding with reinforced frames and additional bracing to handle the unusual load safely.

Advantages of Choosing Customized Liba Steel Build Frames Scaffolding System Solutions

| Advantage | Description |

| Tailored Fit | Custom sizes and configurations ensure scaffolding fits perfectly to project requirements. |

| Enhanced Safety | Custom features reduce risk by addressing specific structural and environmental challenges. |

| Cost Efficiency | Pre-engineered solutions minimize on-site alterations and labor costs. |

| Versatility | Suitable for diverse industries including construction, oil & gas, industrial maintenance. |

| Integration Capability | Can be combined with other Liba products like hoists and mast climbers for full access solutions. |

How to Request Custom Liba Steel Build Frames Scaffolding System Solutions

Step 1: Define Project Requirements

Provide detailed information about your project, including dimensions, load requirements, environmental conditions, and any special considerations.

Step 2: Consult with Liba Experts

Liba's technical team collaborates with clients to design scaffolding solutions tailored to unique needs. They use CAD software and 3D modeling to visualize and optimize the design.

Step 3: Review and Approve Design

Clients review the proposed design and suggest modifications if necessary. This iterative process ensures the final product meets all expectations.

Step 4: Manufacturing and Delivery

Once approved, Liba manufactures the customized scaffolding components using high-quality steel and surface treatments. Components are shipped with detailed assembly instructions.

Step 5: On-Site Assembly and Support

Liba provides technical support during installation to ensure safe and efficient assembly of the customized scaffolding system.

Maintenance and Longevity of Customized Liba Steel Build Frames Scaffolding System Solutions

Customized scaffolding from Liba maintains the same high standards of durability and corrosion resistance as standard products. Proper maintenance includes:

- Regular inspections for wear or damage

- Cleaning and lubricating moving parts

- Storing components in dry conditions

- Replacing worn parts promptly

These practices ensure that customized scaffolding solutions remain safe and functional over multiple projects.

Innovations Driving Customization in Liba Steel Build Frames Scaffolding System Solutions

Liba continuously invests in research and development to enhance the customization capabilities of their scaffolding systems. Some recent technological advancements include:

- Lightweight High-Strength Steel Alloys: These reduce the overall weight of scaffolding components without compromising structural integrity, making customized solutions easier to handle and install.

- Smart Monitoring Systems: Integration of sensors within scaffolding frames to monitor load, stress, and environmental conditions in real-time, enhancing safety especially in customized complex structures.

- Advanced Surface Treatments: New galvanization and coating techniques improve corrosion resistance, particularly important for customized scaffolds used in harsh or marine environments.

- 3D Modeling and Simulation: Use of sophisticated software to simulate scaffolding performance under various load and environmental scenarios, allowing precise customization and risk assessment before manufacturing.

Conclusion

The ability to customize Liba steel build frames scaffolding system solutions is a significant factor in their popularity across the construction and industrial sectors. Their modular design, wide range of components, and expert engineering allow them to be tailored to unique project requirements, ensuring safety, efficiency, and cost-effectiveness. Whether dealing with complex architectural shapes, hazardous environments, or specialized load needs, Liba's customized scaffolding solutions provide reliable and innovative answers. By partnering with Liba, contractors and project managers gain access to scaffolding systems that are not only robust and durable but also precisely adapted to their unique challenges.

FAQ

1. Can Liba steel build frames scaffolding system solutions be customized for any project size?

Yes, Liba offers a wide range of modular components and custom sizes to accommodate projects of all scales, from small renovations to large industrial constructions.

2. How does customization affect the delivery time of Liba scaffolding products?

Customization may add some lead time for design and manufacturing, but Liba works closely with clients to optimize schedules and minimize delays.

3. Are customized Liba scaffolding systems compliant with safety standards?

Absolutely. All customized solutions are designed to meet or exceed international safety regulations and undergo rigorous quality control.

4. Can Liba scaffolding be customized for hazardous environments?

Yes, Liba provides specialized components such as fire-resistant steel boards and corrosion-resistant coatings for use in oil & gas, chemical plants, and other hazardous areas.

5. Does Liba provide technical support for custom scaffolding assembly?

Yes, Liba offers comprehensive technical support and training to ensure safe and efficient assembly of customized scaffolding systems.