Content Menu

● Understanding System Scaffold Components

● The Benefits of System Scaffolds

● Assembly Process for System Scaffold Components

● Visual Aids in Assembly

● Safety Considerations

● Advanced Techniques in Assembly

● Common Challenges in Assembly

● Case Studies

● Conclusion

● FAQ

>> 1. What are the main advantages of using system scaffolding?

>> 2. How do I ensure my scaffold is safe before use?

>> 3. Can I assemble system scaffolding alone?

>> 4. What should I do if I notice damage on a scaffold component?

>> 5. Are there specific regulations I need to follow when using scaffolding?

Scaffolding plays a crucial role in construction, providing essential support and access for workers. Among the various types of scaffolding, system scaffold components have gained popularity due to their modular design and ease of assembly. This article explores how these components are assembled for large-scale projects, highlighting their benefits, assembly techniques, and safety considerations.

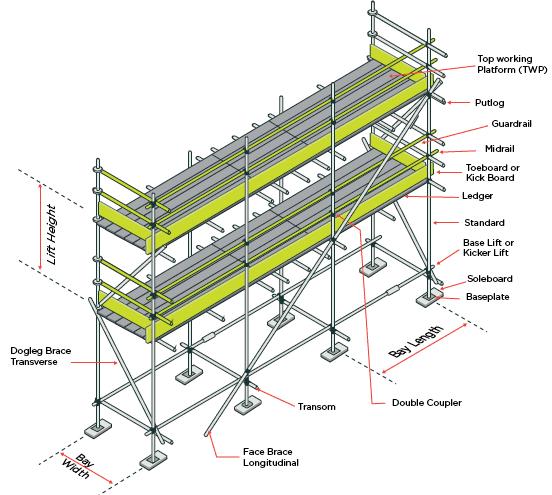

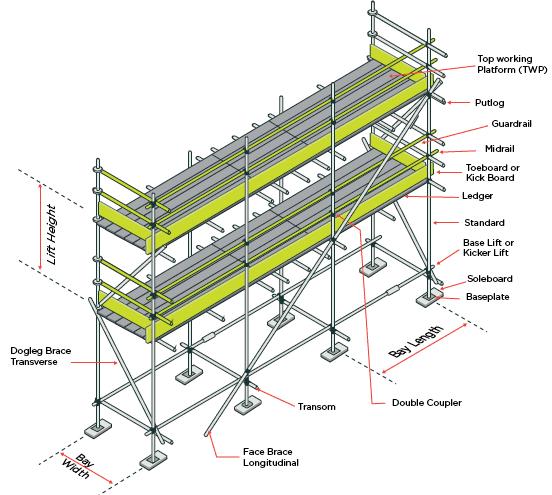

Understanding System Scaffold Components

System scaffolding consists of standardized, pre-engineered components that interlock without the need for traditional fittings. This modular approach allows for quick assembly and disassembly, making it ideal for large-scale projects. Key components include:

- Standards: Vertical posts that provide the main structural support.

- Ledgers: Horizontal members connecting standards to provide stability.

- Transoms: Horizontal cross members supporting the working platform.

- Decking: Platforms made from steel or aluminum where workers stand.

- Base Plates: Components that distribute the load at the bottom of standards.

- Diagonal Braces: Enhance stability by connecting standards and ledgers.

- Guardrails and Toeboards: Safety features to prevent falls.

The Benefits of System Scaffolds

The adoption of system scaffold components offers several advantages:

- Speed of Assembly: The interlocking design allows for rapid setup, often reducing assembly time by up to 50% compared to traditional scaffolding methods.

- Safety: With fewer components and a simpler assembly process, the risk of accidents is minimized. Workers require less training to operate system scaffolds effectively.

- Cost Efficiency: While initial costs may be higher, the time savings in labor and reduced waste make system scaffolding a cost-effective choice for large projects.

- Versatility: System scaffolds can be adapted to various shapes and sizes, making them suitable for different construction needs, from residential buildings to large commercial structures.

Assembly Process for System Scaffold Components

Assembling system scaffold components involves several key steps:

1. Preparation of the Site: Ensure that the ground is stable and level. Use mud sills or base plates to distribute weight evenly.

2. Setting Up Base Plates: Position base plates at designated locations, ensuring they are level and secure.

3. Installing Standards: Insert vertical standards into base plates. Ensure they are plumb using a level.

4. Adding Ledgers: Connect horizontal ledgers between standards at predetermined heights. Use locking mechanisms to secure them in place.

5. Incorporating Transoms: Fit transoms across the width of the scaffold to support decking.

6. Placing Decking: Install decking on top of transoms, ensuring it is securely positioned.

7. Adding Diagonal Braces: Install diagonal braces between standards and ledgers to enhance stability.

8. Finalizing Safety Features: Attach guardrails and toeboards as needed to ensure worker safety.

9. Inspection: Conduct a thorough inspection of all components before use, checking for any signs of wear or damage.

Visual Aids in Assembly

To better understand the assembly process, visual aids such as diagrams and videos can be highly effective. Below are some examples:

- Diagrams showing the layout of system scaffold components can help workers visualize the structure before assembly.

- Videos demonstrating assembly techniques, such as those available on platforms like YouTube, provide step-by-step guidance on erecting system scaffolds safely and efficiently.

Safety Considerations

Safety is paramount when working with scaffolding. Here are essential safety measures:

- Always wear personal protective equipment (PPE), including helmets, harnesses, and non-slip footwear.

- Ensure that all workers are trained in scaffold assembly and safety protocols.

- Regularly inspect scaffolds during use, looking for any signs of instability or damage.

- Follow local regulations regarding scaffold height limits and load capacities.

Advanced Techniques in Assembly

For large-scale projects, advanced techniques can further enhance the efficiency of assembling system scaffold components:

- Prefabrication: In some cases, components can be prefabricated off-site and delivered ready for installation. This reduces on-site labor time and minimizes disruptions caused by weather or other factors.

- Use of Lifting Equipment: Employing cranes or hoists can facilitate the placement of larger scaffold sections, reducing manual handling risks and speeding up the assembly process.

- Digital Tools: Utilizing software for planning scaffold layouts can improve accuracy in design and help manage resources effectively. These tools can simulate load distributions and optimize component usage based on project specifications.

Common Challenges in Assembly

While system scaffolds offer many benefits, certain challenges may arise during assembly:

- Site Conditions: Uneven ground or adverse weather conditions can complicate scaffold setup. It's essential to assess site conditions thoroughly before beginning assembly.

- Component Compatibility: Ensuring that all components are compatible with each other is crucial for structural integrity. Regular audits of inventory can prevent issues related to missing or mismatched parts.

- Worker Training: Although system scaffolding is easier to assemble than traditional methods, proper training is still necessary to ensure that workers understand safety protocols and assembly techniques.

Case Studies

Examining real-world applications provides insight into how system scaffold components are effectively utilized in large-scale projects:

1. High-Rise Construction Project

- A major urban development project utilized system scaffolding to facilitate work on multiple floors simultaneously. The modular design allowed teams to quickly adapt as construction progressed upward while maintaining safety standards through effective guardrail systems.

2. Bridge Renovation

- During a bridge renovation project, system scaffolds were employed to access hard-to-reach areas while minimizing disruption to traffic below. Prefabricated sections were transported to the site, allowing rapid deployment without compromising structural integrity or safety protocols.

3. Industrial Facility Expansion

- An industrial facility expansion required extensive scaffolding due to complex machinery installations at height. The use of digital planning tools enabled precise layout designs that optimized component usage while ensuring worker safety through adequate space management around machinery.

Conclusion

The assembly of system scaffold components for large-scale projects is a streamlined process that enhances efficiency while prioritizing safety. By utilizing standardized parts designed for quick interlocking assembly, construction teams can significantly reduce setup times and costs while ensuring a secure working environment. Advanced techniques such as prefabrication and digital planning further contribute to optimizing this process, allowing construction professionals to tackle even the most challenging projects with confidence.

FAQ

1. What are the main advantages of using system scaffolding?

System scaffolding offers faster assembly times, improved safety due to fewer components, cost efficiency through reduced labor costs, and versatility in adapting to various project shapes.

2. How do I ensure my scaffold is safe before use?

Conduct thorough inspections of all components for damage or wear, ensure proper leveling and stability during assembly, and verify that all safety features like guardrails are in place.

3. Can I assemble system scaffolding alone?

While it is possible to assemble some types of scaffolding alone, it is recommended that at least two people work together to ensure safety and efficiency during the setup process.

4. What should I do if I notice damage on a scaffold component?

Immediately remove any damaged components from service and replace them with new parts before continuing with any work on or around the scaffold.

5. Are there specific regulations I need to follow when using scaffolding?

Yes, adhere to local regulations regarding scaffold use, including height limits, load capacities, and required safety measures as outlined by occupational health and safety guidelines.