Content Menu

● What is Tube and Clamp Scaffolding?

● Why Learn Tube and Clamp Scaffolding?

● Step-by-Step Tube and Clamp Scaffolding Instructions for Beginners

>> 1. Understand the Components and Tools

>> 2. Plan and Draw the Scaffold Structure

>> 3. Prepare the Foundation

>> 4. Assemble the Scaffold Frame

>> 5. Install Platforms and Guardrails

>> 6. Provide Safe Access

>> 7. Inspect and Secure the Scaffold

● Safety Tips for Beginners Using Tube and Clamp Scaffolding

● Common Challenges and How to Overcome Them

● Maintenance and Inspection

● Conclusion

● FAQ

>> 1. What are the basic components of tube and clamp scaffolding?

>> 2. How do I ensure the scaffold is safe to use?

>> 3. Can beginners assemble tube and clamp scaffolding without training?

>> 4. What tools are needed for scaffold assembly?

>> 5. How do I prevent scaffold collapse?

Tube and clamp scaffolding is one of the most versatile and widely used scaffolding systems in construction and maintenance projects. For beginners, learning to use this type of scaffolding can seem daunting due to its customizable nature and the variety of components involved. However, with the right tube and clamp scaffolding instructions, training, and safety awareness, beginners can quickly become proficient in erecting, using, and dismantling these scaffolds safely and efficiently.

What is Tube and Clamp Scaffolding?

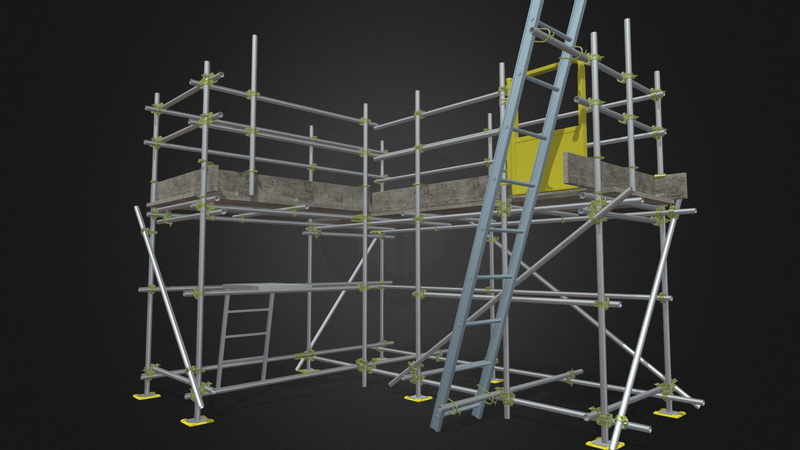

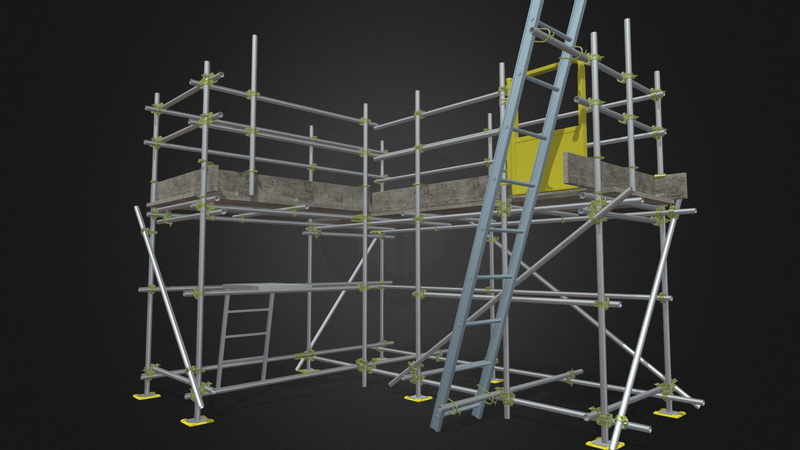

Tube and clamp scaffolding, also called tube and coupler scaffolding, consists of steel tubes connected by clamps (couplers) to form a sturdy, flexible framework. Unlike modular scaffolding systems, it requires manual assembly of tubes and clamps, allowing it to be adapted to complex shapes and irregular surfaces.

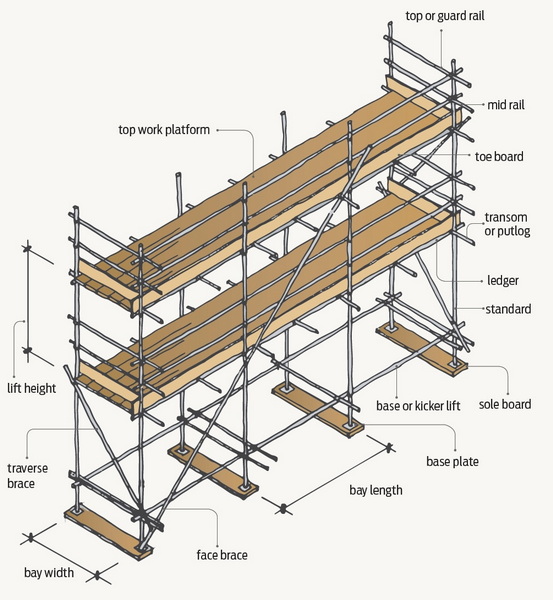

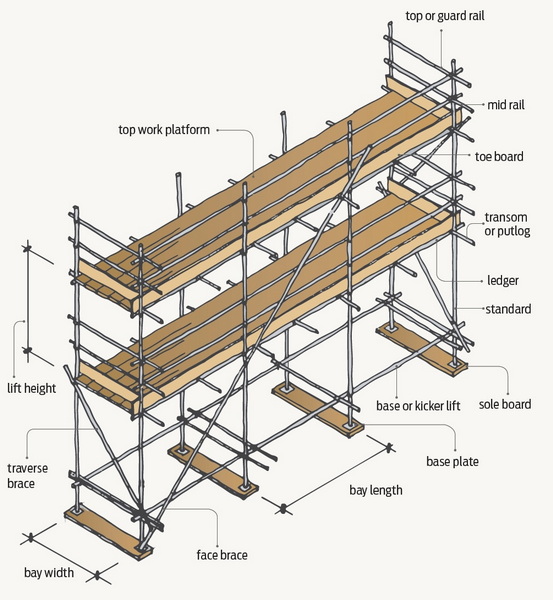

Key Components:

- Tubes: Steel pipes that form the main structure.

- Clamps (Couplers): Devices that join tubes at various angles; primarily right-angle clamps and swivel clamps.

- Base Plates: Plates placed under the tubes to distribute load and stabilize the scaffold.

- Boards/Platforms: Wooden or metal planks placed on the scaffold frame to create working surfaces.

- Braces: Diagonal tubes or components that provide additional stability and prevent swaying.

Why Learn Tube and Clamp Scaffolding?

- Flexibility: Can be assembled to fit irregular or complex structures.

- Strength: Capable of supporting heavy loads.

- Customizable: Tubes can be cut to length and connected at any angle.

- Widely Used: Common in industrial, petrochemical, and restoration projects.

Step-by-Step Tube and Clamp Scaffolding Instructions for Beginners

1. Understand the Components and Tools

Before starting assembly, familiarize yourself with the tubes, clamps, base plates, and platforms. Also, ensure you have the necessary tools such as:

- Scaffold spanners or wrenches for tightening clamps.

- Measuring tape.

- Spirit level.

- Safety equipment (hard hats, gloves, harnesses).

2. Plan and Draw the Scaffold Structure

Begin with a clear drawing or plan of the scaffold layout, including:

- Dimensions and height.

- Platform locations.

- Access points (ladders or stairs).

- Brace and guardrail placements.

- Load requirements.

Planning helps ensure safety and efficiency during assembly.

3. Prepare the Foundation

A stable, level foundation is critical. Use base plates on firm ground or mudsills on soft or uneven surfaces to prevent sinking or tilting. Check that the ground can support the scaffold's weight plus workers and materials.

4. Assemble the Scaffold Frame

- Start from the ground up.

- Connect vertical tubes (standards) using right-angle clamps to horizontal tubes (ledgers).

- Use swivel clamps to add diagonal braces for stability.

- Build the scaffold in manageable sections or zones, connecting each securely.

5. Install Platforms and Guardrails

Place scaffold boards or platforms across the horizontal tubes to create safe working surfaces. Install guardrails and mid-rails around platforms to prevent falls. Toe boards should also be fitted to prevent tools or materials from falling.

6. Provide Safe Access

Attach ladders or stairways securely to the scaffold to provide safe access for workers. Ensure access points are free from obstructions and well-lit.

7. Inspect and Secure the Scaffold

- Check all clamps are tight and secure.

- Verify vertical alignment (plumb) and horizontal level.

- Ensure braces are correctly installed to prevent swaying.

- Attach scaffold tags indicating the scaffold's safety status (green for safe, red for unsafe).

Safety Tips for Beginners Using Tube and Clamp Scaffolding

Safety is the cornerstone of any scaffolding work. Beginners must adhere to strict safety protocols to prevent accidents and injuries.

- Wear Personal Protective Equipment (PPE): Always use hard hats, gloves, safety boots, and fall arrest harnesses when working at heights.

- Training and Supervision: Only trained and competent personnel should erect or dismantle scaffolds. Beginners should work under supervision until fully competent.

- Load Limits: Never exceed the scaffold's load capacity. Overloading can lead to collapse.

- Daily Inspections: Inspect scaffolding daily and after adverse weather conditions such as heavy rain or strong winds.

- Electrical Safety: Avoid erecting scaffolds near energized power lines. Maintain safe distances to prevent electrocution.

- Fall Protection: Use guardrails, mid-rails, toe boards, and personal fall arrest systems when working at heights over 10 feet (3 meters).

Common Challenges and How to Overcome Them

| Challenge | Solution |

| Difficulty fitting tubes at odd angles | Use swivel clamps designed for any angle connections |

| Uneven ground causing instability | Use mudsills and base plates for level support |

| Loose clamps after assembly | Use proper tightening tools and check clamps regularly |

| Complex scaffold shapes | Detailed planning and modular assembly in zones |

Maintenance and Inspection

Regular maintenance and inspection are essential to ensure the longevity and safety of tube and clamp scaffolding.

- Inspect Tubes and Clamps: Look for signs of corrosion, cracks, or deformation.

- Clean Components: Remove dirt, grease, and rust to prevent deterioration.

- Lubricate Clamps: Apply oil or grease to clamps to facilitate tightening and prevent rust.

- Store Properly: Store scaffolding components in a dry, covered area to avoid weather damage.

- Replace Damaged Parts: Never use damaged tubes or clamps; replace them immediately.

Conclusion

For beginners, learning to use tube and clamp scaffolding effectively requires understanding its components, planning the scaffold layout, preparing a stable foundation, and following step-by-step assembly instructions. Safety must always be a priority, with proper PPE, training, and scaffold inspections. The flexibility and strength of tube and clamp scaffolding make it an excellent choice for complex projects, and with the right tube and clamp scaffolding instructions, beginners can confidently erect and use these scaffolds safely.

FAQ

1. What are the basic components of tube and clamp scaffolding?

The main components are steel tubes, right-angle and swivel clamps, base plates, platforms, and braces that provide structure and stability.

2. How do I ensure the scaffold is safe to use?

Conduct daily inspections, ensure clamps are tight, platforms are secure, guardrails are installed, and the scaffold is built on a stable foundation.

3. Can beginners assemble tube and clamp scaffolding without training?

No, due to the complexity and safety risks, beginners should receive proper training and supervision before assembling scaffolding.

4. What tools are needed for scaffold assembly?

Scaffold spanners or wrenches, measuring tape, spirit level, and personal protective equipment are essential.

5. How do I prevent scaffold collapse?

Use proper bracing, do not overload the scaffold, secure all clamps tightly, and build on level, firm ground.