Content Menu

● Introduction to Cuplock Scaffolding

● Key Components of Cuplock Scaffolding

● Factors Influencing Load Capacity

>> Design and Configuration

>> Type of Construction

>> Foundation Stability

● Typical Load Capacities

● Ensuring Safety and Compliance

● Advanced Techniques for Enhanced Load Capacity

>> Optimizing Scaffolding Design

>> Innovative Materials and Technologies

● Case Studies

>> Example 1: High-Rise Building Facade Renovation

>> Example 2: Bridge Maintenance

● Conclusion

● FAQ

>> 1. What are the typical dimensions of Cuplock scaffolding standards?

>> 2. How does the spacing of standards affect load capacity?

>> 3. What materials are commonly used for Cuplock scaffolding?

>> 4. What are the general load capacity guidelines for Cuplock scaffolding?

>> 5. Why is regular inspection important for Cuplock scaffolding?

● Citations:

Cuplock scaffolding is a widely used system in the construction industry due to its versatility, strength, and ease of assembly. One critical aspect that affects its performance is the dimensions of its components, which significantly influence its load capacity. Understanding how cuplock scaffolding dimensions impact load capacity is essential for ensuring safety and efficiency on construction sites.

Introduction to Cuplock Scaffolding

Cuplock scaffolding is a modular system composed of vertical standards and horizontal ledgers, connected by a unique "cup and blade" locking mechanism. This design allows for quick assembly and disassembly, saving time and labor costs. The system is ideal for various applications, including building facades, bridges, and industrial maintenance.

Key Components of Cuplock Scaffolding

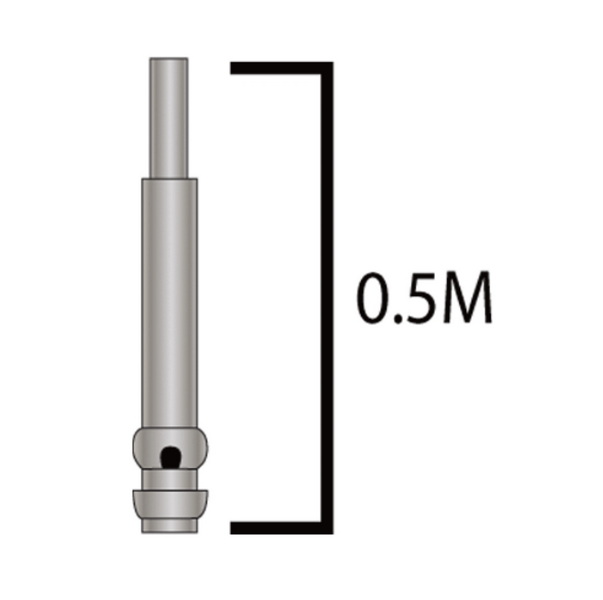

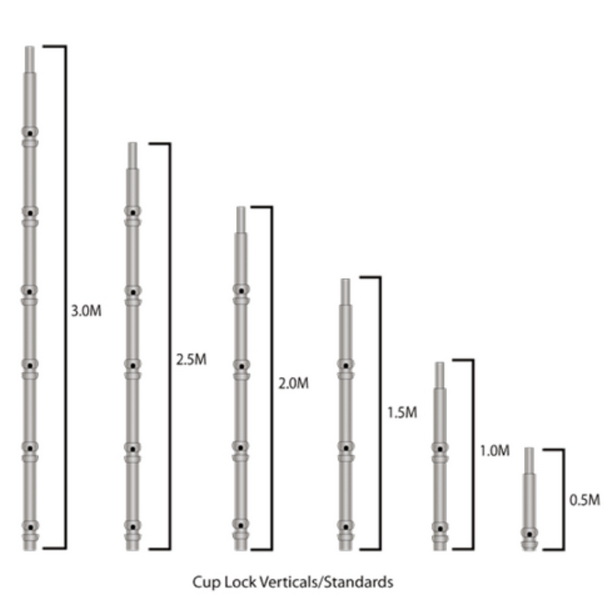

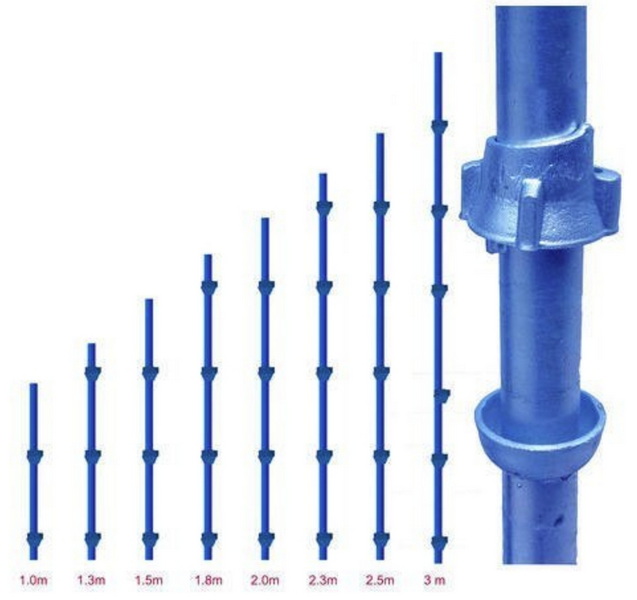

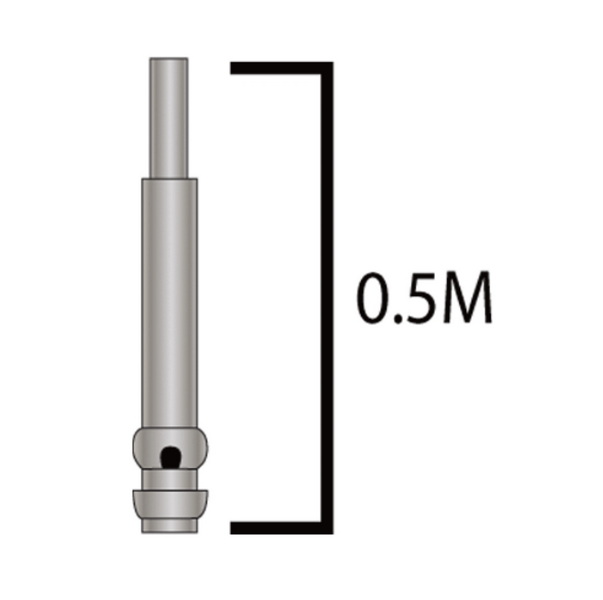

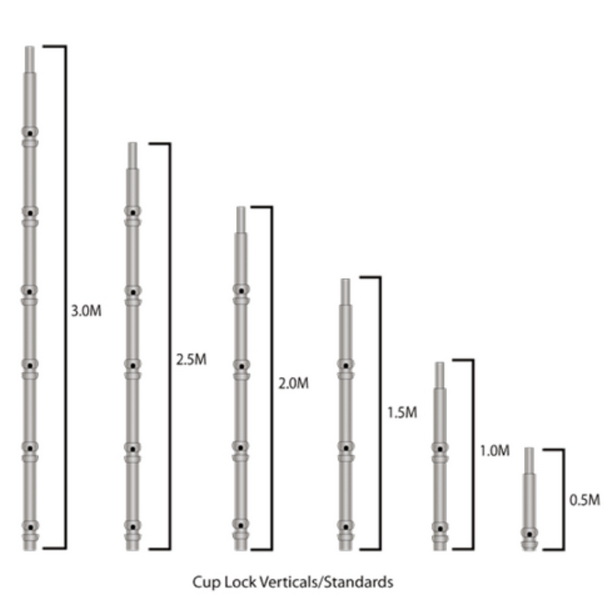

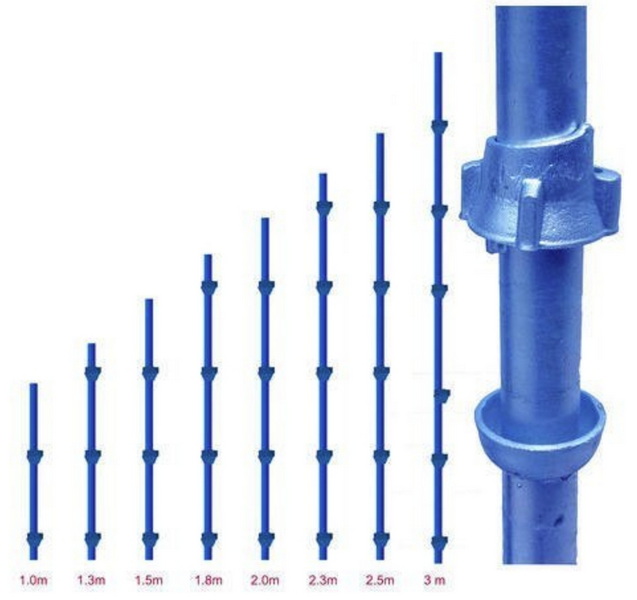

1. Standards (Verticals): These are the backbone of the Cuplock system, typically with an outer diameter of 48.3 mm and lengths ranging from 0.5 meters to 3 meters. For projects requiring greater heights, these standards can be connected using spigot joints.

2. Ledgers (Horizontals): These define the width or length of the scaffold platform. Standard lengths vary, with common sizes including 0.6 meters, 1.2 meters, 1.8 meters, and 2.4 meters.

3. Transoms: These support the decking or boards and often have the same length options as ledgers to maintain uniformity across the scaffold structure.

Factors Influencing Load Capacity

The load capacity of Cuplock scaffolding is influenced by several factors, including:

Cuplock scaffolding is typically made from high-strength steel, such as S355 or S235. The grade and quality of the steel directly impact the system's overall strength and load-bearing capacity.

Design and Configuration

The architectural design of the Cuplock system, including the spacing of standards and ledgers, affects its ability to distribute and bear weight. Closer spacing can support heavier loads.

Type of Construction

The load capacity varies depending on whether the scaffolding is used for light-duty tasks (such as painting or electrical work) or heavy-duty applications (like supporting concrete slabs during curing).

Foundation Stability

A stable and well-prepared base prevents excessive stress and potential failure. External factors such as wind load, vibrations, or additional weight from construction materials and equipment can influence performance.

Typical Load Capacities

While specific load capacities can vary based on the manufacturer's design and the configuration of the scaffolding, Cuplock systems generally fall into three main categories:

- Light-Duty (Low Load): Suitable for tasks involving a few workers and hand tools, light-duty scaffolding can typically support around 75 kg per square meter.

- Medium-Duty (Standard Load): Used for more intensive work with multiple workers, materials, and heavier tools, medium-duty scaffolding can support approximately 150 kg per square meter.

- Heavy-Duty (High Load): Designed for projects requiring significant material storage or heavy equipment, heavy-duty scaffolding can bear loads of 275 kg per square meter or more.

Ensuring Safety and Compliance

To maintain safety and structural integrity, it's essential to:

1. Consult Manufacturer Specifications: Always refer to the manufacturer's guidelines for specific load capacities and adhere to recommended limits.

2. Conduct Regular Inspections: Ensure that the scaffolding is inspected by a competent person before use and regularly thereafter, especially after any alterations or exposure to adverse weather conditions.

3. Distribute Weight Evenly: Load distribution is key to preventing overloading. Ensure that materials are evenly spread out across the platform and that heavy loads are placed directly over the standards.

4. Train Workers: All personnel should be aware of the load limits and trained in the proper use and handling of materials on the scaffolding.

5. Use Proper Safety Equipment: Ensure that all workers use appropriate personal protective equipment (PPE) and follow safety protocols to minimize risks.

Advanced Techniques for Enhanced Load Capacity

Optimizing Scaffolding Design

1. Modular Configuration: Utilize modular designs that allow for easy expansion or contraction of the scaffolding structure as needed. This flexibility can help optimize load distribution and reduce unnecessary weight.

2. Dynamic Load Assessment: Conduct dynamic assessments to account for factors like wind resistance and vibrations, which can impact the scaffolding's stability and load capacity.

Innovative Materials and Technologies

1. High-Strength Materials: Incorporate advanced materials with higher strength-to-weight ratios to enhance load capacity without increasing the overall weight of the scaffolding.

2. Digital Monitoring Systems: Implement digital monitoring systems to track real-time load conditions and provide early warnings for potential overloading.

Case Studies

Example 1: High-Rise Building Facade Renovation

In a recent high-rise building renovation project, Cuplock scaffolding was used to support extensive facade work. By optimizing the scaffolding design with closer standard spacing and using high-strength materials, the project team was able to safely support heavy-duty equipment and materials, ensuring timely completion without compromising safety.

Example 2: Bridge Maintenance

For a major bridge maintenance project, Cuplock scaffolding was chosen due to its versatility and ability to withstand harsh environmental conditions. The scaffolding was configured to maximize load capacity while minimizing visual impact, allowing for efficient and safe execution of the maintenance work.

Conclusion

The dimensions of Cuplock scaffolding play a crucial role in determining its load capacity. By understanding how these dimensions affect load-bearing capabilities, project managers and workers can ensure the safety and efficiency of construction projects. Always prioritize compliance with manufacturer specifications and safety standards to maintain the integrity and reliability of your scaffolding setup.

FAQ

1. What are the typical dimensions of Cuplock scaffolding standards?

Cuplock scaffolding standards typically have an outer diameter of 48.3 mm and lengths ranging from 0.5 meters to 3 meters.

2. How does the spacing of standards affect load capacity?

Closer spacing between standards allows for better weight distribution, enabling the scaffolding to support heavier loads.

3. What materials are commonly used for Cuplock scaffolding?

Cuplock scaffolding is typically made from high-strength steel, such as S355 or S235, ensuring durability and load-bearing strength.

4. What are the general load capacity guidelines for Cuplock scaffolding?

Cuplock scaffolding generally falls into three categories: light-duty (75 kg/m²), medium-duty (150 kg/m²), and heavy-duty (275 kg/m² or more).

5. Why is regular inspection important for Cuplock scaffolding?

Regular inspections ensure that the scaffolding remains structurally sound and safe for use, especially after alterations or exposure to adverse weather conditions.

Citations:

[1] https://primesteeltech.co.in/what-is-the-load-capacity-of-a-cuplock-scaffold.html

[2] https://shelterrc.com/what-is-the-load-capacity-of-a-cuplock-scaffold/

[3] https://rapid-scafform.com/cuplock-scaffold/

[4] https://blog.csdn.net/weixin_40289064/article/details/79669930

[5] https://primesteeltech.co.in/what-size-are-cuplock-scaffolds.html

[6] https://www.wm-scaffold.com/cup-lock-scaffold.html

[7] https://jumplyscaffolding.com/what-is-cuplock-scaffolding/

[8] https://www.sparsteel.com/blog/cuplock-scaffolding-types-uses-and-benefits/

[9] https://scaffco.com/wp-content/uploads/2020/04/07-Cuplock-System.pdf