Content Menu

● Understanding System Scaffold Stair Towers

● Key Components of a System Scaffold Stair Tower

● How System Scaffold Stair Towers Improve Safety

● Best Practices for Using System Scaffold Stair Towers

● Conclusion

● FAQ

>> 1. What is a system scaffold stair tower?

>> 2. How do system scaffold stair towers improve safety?

>> 3. What are the key components of a system scaffold stair tower?

>> 4. Why are regular inspections important for system scaffold stair towers?

>> 5. What are some best practices for using system scaffold stair towers?

● Citations:

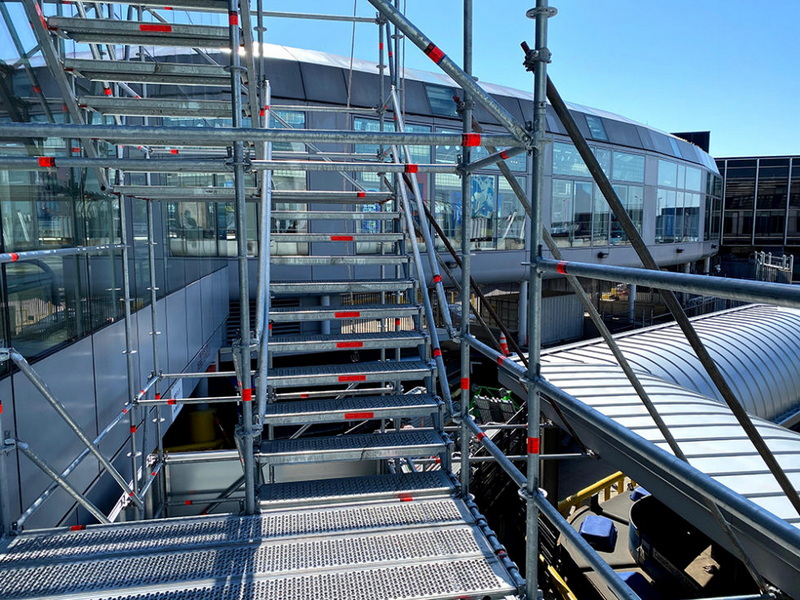

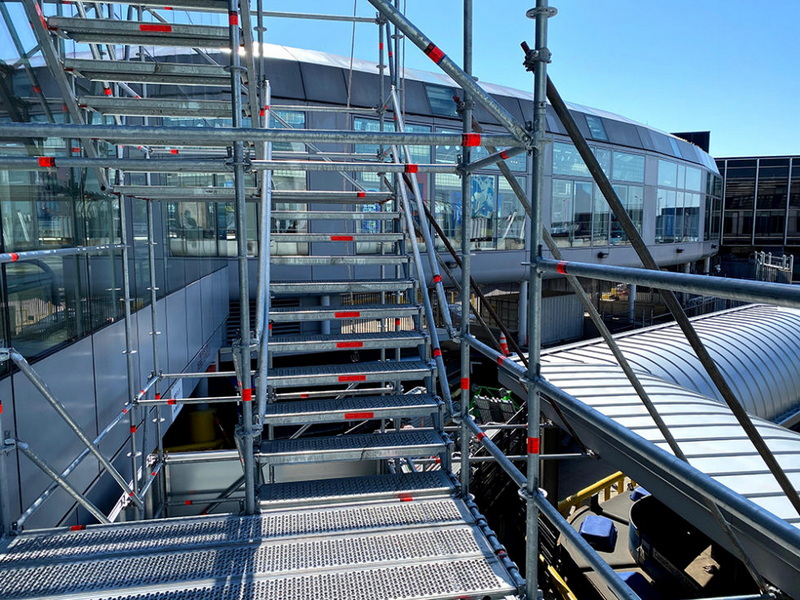

In the construction industry, ensuring worker safety is a paramount concern. Working at heights poses significant risks, making it essential to implement safety measures that protect workers from falls and other potential injuries. System scaffold stair towers have emerged as a crucial tool in enhancing safety and improving efficiency on construction sites. This article delves into the numerous ways system scaffold stair towers improve construction safety, supported by relevant research and examples.

Understanding System Scaffold Stair Towers

A system scaffold stair tower is a temporary structure designed to provide safe and efficient access to elevated work areas on construction sites. Unlike traditional ladders, system scaffold stair towers offer a stable and secure means of ascending and descending, reducing the risk of accidents and injuries. These towers are constructed from modular scaffolding components, allowing for customization and adaptability to various project needs.

Key Components of a System Scaffold Stair Tower

1. Stair Units: Interconnected stair units that allow access to different levels of the scaffold[4].

2. Vertical Frames: Provide the main structural support for the stair tower.

3. Horizontal Ledgers: Connect vertical frames and provide additional support.

4. Diagonal Braces: Enhance stability and prevent lateral movement.

5. Handrails: Provide a secure grip for workers as they climb or descend the stairs[2].

6. Non-Slip Treads: Aluminum or steel treads with non-slip surfaces to maximize grip in all weather conditions[7].

How System Scaffold Stair Towers Improve Safety

1. Safe and Efficient Access

- System scaffold stair towers provide a secure and reliable means of accessing elevated work areas[2]. Unlike traditional ladders, stair towers offer a stable and sturdy platform for workers to climb up and down[2]. The inclusion of handrails and non-slip surfaces further enhances safety, minimizing the risk of accidents and injuries[2].

- "Stair tower scaffolding provides a secure and reliable means of accessing elevated work areas. Unlike traditional ladders, stair towers offer a stable and sturdy platform for workers to climb up and down. The inclusion of handrails and non-slip surfaces further enhances safety, minimizing the risk of accidents and injuries"[2].

2. Reduced Risk of Falls

- Falls are the greatest danger when working with stair towers[1]. System scaffold stair towers minimize this risk by providing a stable and secure means of ascent and descent[2]. The use of handrails, non-slip surfaces, and guardrails further reduces the likelihood of falls[2].

- The bottom of the stringers should be designed to prevent slips while the treads should have a coarse non-slip surface to provide added grip[5].

- "When ascending or descending the stair tower, be sure to: Use the handrails for support and balance. Face the stairs and maintain a firm grip on the handrails. Take one step at a time, avoiding rushing or skipping steps. Keep the stair tower clear of debris or obstacles that may cause slips or falls"[2].

3. Improved Ergonomics

- Carrying heavy items up and down ladders can lead to manual injuries[1]. System scaffold stair towers make it easier for workers to transport materials and equipment to elevated work areas[2]. This reduces the physical strain on workers and minimizes the risk of musculoskeletal injuries[1].

- "It is critical to take steps to lessen this potential risk [manual injuries]"[1].

4. Enhanced Stability

- Ensuring the stability of the stair tower is essential for safe use[2]. System scaffold stair towers are designed to provide a stable and secure platform for workers[2]. The use of bracing and connectors further enhances stability and prevents lateral movement[2].

- "Ensure that the base of the stair tower is securely placed on a level and stable surface. Avoid overloading the scaffold beyond its specified weight capacity. Do not move or reposition the stair tower while workers are on it"[2].

5. Unobstructed Work Areas

- One of the key benefits of system scaffold stair towers is that it ensures undisturbed work areas on each scaffold level[2]. With separate stair access points, workers can enter and exit the scaffolding without disrupting ongoing work[2]. This seamless flow maximizes productivity by minimizing interruptions and maintaining focused, uninterrupted work environments[2].

- "With separate stair access points, workers can enter and exit the scaffolding without disrupting ongoing work. This seamless flow maximizes productivity by minimizing interruptions and maintaining focused, uninterrupted work environments"[2].

6. Efficient Material Transport

- Construction stair towers offer a reliable and efficient solution for managing material transport and scaffold utilization on construction sites[2]. With their adaptable nature and load-bearing capabilities, these structures provide a solid foundation for productive and safe construction operations[2].

- "Construction stair towers offer a reliable and efficient solution for managing material transport and scaffold utilization on construction sites. With their adaptable nature and load-bearing capabilities, these structures provide a solid foundation for productive and safe construction operations"[2].

7. Compliance with Safety Regulations

- Using system scaffold stair towers helps construction companies comply with safety regulations and standards set by organizations like OSHA[1]. Adhering to these regulations demonstrates a commitment to worker safety and can help avoid costly penalties[1].

- "That's why there are regulations governing the safe use and erection of stair towers"[1].

Best Practices for Using System Scaffold Stair Towers

1. Proper Erection and Dismantling: Many of the risks are amplified when the stair tower is being assembled or dismantled. It is for this reason why safety is paramount throughout the use of the stair tower[1].

2. Regular Inspections: At Layher, we can't emphasize enough that pre-use checks and inspections should be done before using stair tower scaffolding. It is crucial[1].

3. Competent Personnel: You must pay attention to the details and follow all of the assembly instructions closely so that only experienced personnel erect and dismantle the stair tower[1].

4. Weather Considerations: Do not use the stair tower scaffold when the weather is inclement (i.e., rain, snow, or heavy wind)[1].

5. Proper Training: Always ensure that your workers have the proper training to be using the scaffolding and are wearing the necessary PPE[1].

Conclusion

System scaffold stair towers offer a multitude of safety benefits that make them an indispensable tool in the construction industry. Their design promotes stability, reduces the risk of falls, improves ergonomics, and facilitates efficient material transport. By investing in high-quality system scaffold stair towers and adhering to best practices, construction companies can create a safer and more productive working environment for their employees. Embracing system scaffold stair towers is not just a matter of adhering to regulations; it is a proactive step towards safeguarding the well-being of workers and ensuring the successful completion of construction projects.

FAQ

1. What is a system scaffold stair tower?

A system scaffold stair tower is a temporary structure designed to provide safe and efficient access to elevated work areas on construction sites.

2. How do system scaffold stair towers improve safety?

They improve safety by providing a stable and secure means of ascending and descending, reducing the risk of falls, improving ergonomics, and facilitating efficient material transport.

3. What are the key components of a system scaffold stair tower?

Key components include stair units, vertical frames, horizontal ledgers, diagonal braces, handrails, and non-slip treads.

4. Why are regular inspections important for system scaffold stair towers?

Regular inspections help identify and address any signs of damage or wear-and-tear, ensuring the structural integrity and stability of the stair tower.

5. What are some best practices for using system scaffold stair towers?

Best practices include proper erection and dismantling, regular inspections, using competent personnel, considering weather conditions, and ensuring proper training for workers.

Citations:

[1] https://layherna.com/l/stair-tower-scaffolding-safety/

[2] https://scaffoldtype.com/staircase-tower-scaffolding/

[3] https://www.ihsa.ca/rtf/health_safety_manual/pdfs/equipment/Scaffolds.pdf

[4] https://www.strongholdhire.com.au/main-types-scaffold-stairs/

[5] https://www.safetyresources.com/scaffold-stair-systems-provide-safe-access

[6] https://scaffoldexpress.com/collections/systems-scaffolding/products/21-ring-lock-system-scaffold-stair-tower

[7] https://www.acescaffolding-uk.com/articles/scaffold-staircases

[8] https://www.ccohs.ca/oshanswers/safety_haz/platforms/scaffolduse.html