Content Menu

● What Is H Frame Scaffolding?

● Why Choosing the Right Size Matters

● H Frame Scaffolding Standard Sizes

>> Standard Heights

>> Standard Widths

● How to Choose the Right H Frame Scaffolding Size

>> 1. Project Height

>> 2. Working Area Size

>> 3. Load Requirements

>> 4. Site Conditions

>> 5. Compliance and Safety

>> 6. Accessibility and Mobility

>> 7. Environmental Considerations

● Sample Calculation: Sizing for a 10 m Long, 6 m High Façade

● Custom and Non-Standard Sizes

● Practical Tips for Choosing H Frame Scaffolding Standard Size

● Common Mistakes to Avoid

● Maintenance and Inspection of H Frame Scaffolding

● Case Study: Choosing H Frame Scaffolding for a High-Rise Project

● Innovations in H Frame Scaffolding

● Environmental Impact and Sustainability

● Conclusion

● FAQ

>> 1. What is the most common H frame scaffolding standard size?

>> 2. Can H frame scaffolding be customized for special projects?

>> 3. How high can H frame scaffolding be safely stacked?

>> 4. What are the main safety features required for H frame scaffolding?

>> 5. How do I calculate the number of H frames needed for my project?

Selecting the correct H frame scaffolding size is fundamental to ensuring safety, efficiency, and cost-effectiveness in any construction or maintenance project. With a multitude of standard sizes, regional variations, and project-specific requirements, understanding how to choose the right H frame scaffolding standard size can be the difference between a successful build and a hazardous site.

What Is H Frame Scaffolding?

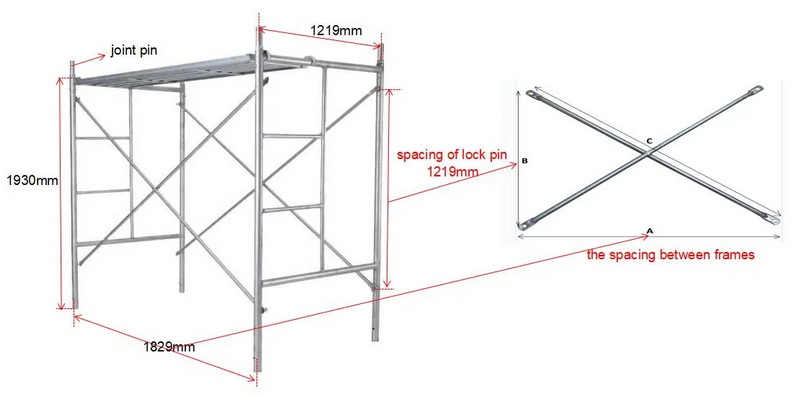

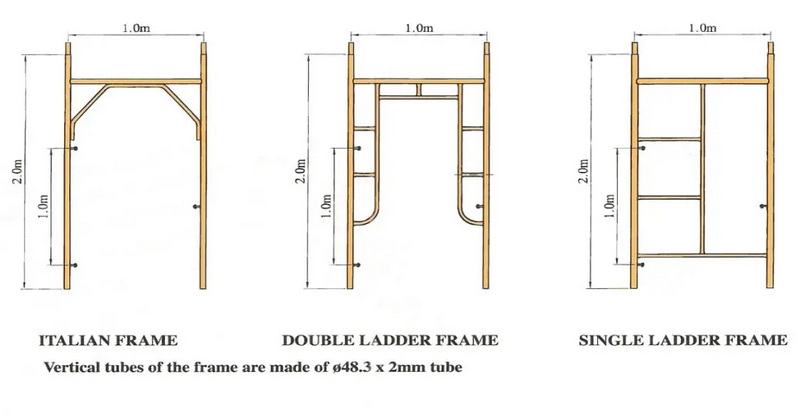

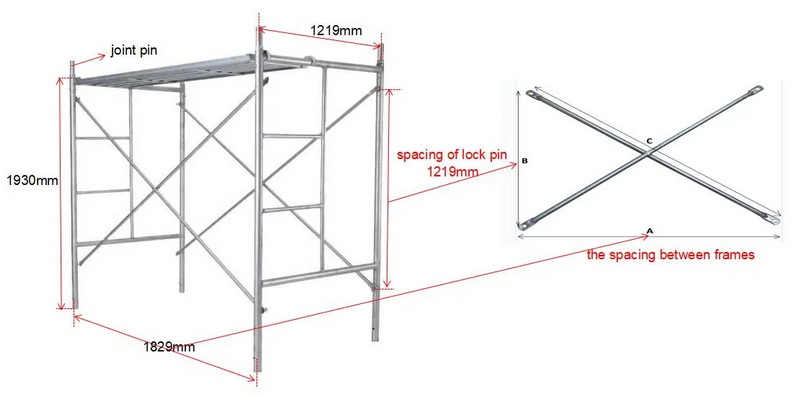

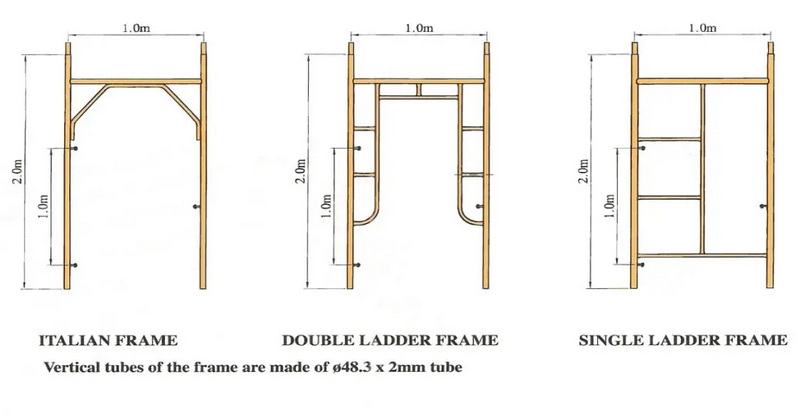

H frame scaffolding is a modular system consisting of vertical frames shaped like the letter "H," connected by cross braces and horizontal ledgers. This structure provides a stable, elevated platform for workers and materials, making it a staple in construction, maintenance, and industrial projects.

Key Components:

- H Frames: The vertical backbone, providing support and stability.

- Cross Braces: Diagonal connectors ensuring rigidity.

- Horizontal Ledgers: Support beams for platforms.

- Platforms/Planks: Surfaces for workers and materials.

- Base Plates/Jacks: Foundation elements for stability and height adjustment.

- Guardrails/Toe Boards: Safety features to prevent falls.

Why Choosing the Right Size Matters

The size of your H frame scaffolding directly impacts:

- Safety: Proper sizing prevents overloading and instability.

- Efficiency: The right size streamlines workflow and minimizes assembly time.

- Cost: Avoids unnecessary material costs or delays due to incorrect sizing.

- Compliance: Meets local safety regulations and standards.

Choosing the correct size is not just about fitting the space; it's about ensuring that the scaffolding can safely support the intended load, provide enough workspace, and adapt to the unique conditions of your job site. Using the wrong size can result in unsafe working conditions, increased risk of accidents, and potential legal liabilities.

H Frame Scaffolding Standard Sizes

Standard Heights

Height (mm) | Height (ft) | Typical Use Case |

914 | 3 | Low-level access, interiors |

1219 | 4 | Interior, general construction |

1524 | 5 | Versatile, mid-size projects |

1700 | 5.6 | General construction |

1930 | 6.3 | General, high-reach |

2000 | 6.5 | High-rise, wide spans |

2400 | 7.9 | Extra height applications |

2500 | 8.2 | Extra height, special projects |

Standard Widths

Width (mm) | Width (ft) | Typical Use Case |

762 | 2.5 | Narrow spaces |

914 | 3 | Standard, residential |

1000 | 3.3 | General construction |

1200 | 3.9 | Wide platforms |

1219 | 4 | Regional standard (Asia/Europe) |

1250 | 4.1 | Wide platforms |

1500 | 4.9 | Extra workspace |

2000 | 6.6 | Wide spans, high-rise |

Cross Braces: Commonly 1000, 1250, 1500, 2000, 2500 mm in length.

Base Plates: 100×100 mm up to 150×150 mm; jack height usually up to 600 mm.

Guardrails: Typically 1000 mm above the platform; toe boards 150 mm high.

Regional Variations:

- Southeast Asia: 1219 mm width is common.

- Europe: 1000, 1219, 1500, 2000 mm widths.

- North America: 2', 3', 4', 5' widths; heights from 3' to 8'.

- South America: Custom sizes per local regulations.

How to Choose the Right H Frame Scaffolding Size

1. Project Height

- Stackable Design: H frames are modular; stack frames to reach the desired working height.

- Standard Practice: Use 2 m frames; stack three for a 6 m total height.

- Safety: Consider maximum stacking height per manufacturer and local regulations.

2. Working Area Size

- Frame Width: Choose wider frames (e.g., 1219 mm or 4 ft) for more workspace; narrow frames (e.g., 914 mm or 3 ft) for tight spaces.

- Bay Length: Match bay length to the façade or work area; common lengths are 7–10 ft.

3. Load Requirements

- Light Duty: Up to 120 kg/m²

- Medium Duty: Up to 240 kg/m²

- Heavy Duty: Up to 360 kg/m² or more

- Tip: Larger and thicker frames support heavier loads; always check load ratings.

4. Site Conditions

- Base Plates/Jacks: Use adjustable jacks for uneven ground; ensure stable foundation.

- Weather Protection: Galvanized or powder-coated frames for outdoor use.

5. Compliance and Safety

- Guardrails/Toe Boards: Ensure all safety features are included and correctly sized.

- Inspection: Regularly check for wear, deformation, or corrosion.

- Training: Only trained personnel should assemble and use scaffolding.

6. Accessibility and Mobility

- Access Points: Consider the need for ladders or stairways within the scaffolding.

- Mobility: For projects requiring frequent repositioning, opt for frames that can accommodate caster wheels.

7. Environmental Considerations

- Wind Loads: In windy environments, select heavier-duty frames or additional bracing.

- Corrosive Environments: Use galvanized or stainless steel frames for chemical plants or coastal areas.

Sample Calculation: Sizing for a 10 m Long, 6 m High Façade

- Frame Height: 2 m frames; stack 3 for 6 m total height.

- Frame Width: 1219 mm (1.2 m) per bay.

- Number of Bays: 10 m / 1.2 m ≈ 8 bays.

- Cross Braces: Match the number of bays and height levels.

- Platforms: Length matches bay width; width as required.

- Base Plates/Jacks: One per vertical frame leg.

Custom and Non-Standard Sizes

Manufacturers can fabricate custom H frame scaffolding for unique project needs:

- Non-standard heights or widths

- Special bracing lengths

- Heavy-duty frames

- Custom finishes (galvanized, painted, powder-coated)

Custom scaffolding may be necessary for:

- Unusual building shapes

- Projects with high load requirements

- Sites with limited access or restricted space

Practical Tips for Choosing H Frame Scaffolding Standard Size

- Always use compatible parts from the same manufacturer.

- Do not mix sizes or brands; this can compromise safety.

- Follow local codes and manufacturer instructions.

- Store frames and braces by size in dry, covered areas.

- Replace damaged parts with exact size and specification.

Common Mistakes to Avoid

- Inadequate Training: Only trained personnel should assemble and dismantle scaffolding.

- Ignoring Manufacturer Guidelines: Always follow weight limits and assembly instructions.

- Skipping Inspections: Regularly check for damage or wear.

- Improper Foundation: Ensure scaffolding is placed on a stable, level surface.

- Neglecting Fall Protection: Install guardrails and use PPE at all times.

Maintenance and Inspection of H Frame Scaffolding

Proper maintenance and regular inspection are crucial for the longevity and safety of your H frame scaffolding. Here are some best practices:

- Daily Visual Checks: Inspect for visible damage, rust, or deformation.

- Weekly Detailed Inspections: Check all joints, welds, and connections.

- After Severe Weather: Inspect for movement, loosening, or water damage.

- Cleaning: Remove debris, mud, and concrete splashes regularly.

- Storage: Store frames off the ground in a dry, covered area to prevent corrosion.

Case Study: Choosing H Frame Scaffolding for a High-Rise Project

Project: 15-story residential tower

Requirements:

- Working height: 45 meters

- Façade length: 60 meters

- Heavy-duty load for bricklaying and material storage

Solution:

- Frame Height: 2 m (6.5 ft) – 23 frames stacked per column

- Frame Width: 1219 mm (4 ft) for ample workspace

- Number of Bays: 60 m / 1.2 m = 50 bays per level

- Cross Braces: Heavy-duty, galvanized for outdoor durability

- Platforms: Steel planks for high load capacity

- Safety: Full guardrails, toe boards, and regular safety inspections

This setup provided a safe, stable, and efficient working environment, meeting both productivity and safety standards.

Innovations in H Frame Scaffolding

With advancements in materials and design, modern H frame scaffolding systems offer:

- Lightweight Aluminum Frames: Easier handling and transport

- Quick-Lock Mechanisms: Faster assembly and disassembly

- Integrated Safety Features: Built-in guardrails, anti-slip platforms

- Digital Monitoring: RFID tags for tracking and inspection records

Environmental Impact and Sustainability

Many manufacturers now offer eco-friendly scaffolding solutions:

- Recycled Steel: Reduces environmental footprint

- Powder-Coated Finishes: Non-toxic and durable

- Modular Design: Reduces waste and extends lifespan

Choosing the right size and type of scaffolding can also minimize material use and transportation emissions.

Conclusion

Choosing the right H frame scaffolding size is a critical step in ensuring the safety, efficiency, and success of your construction or maintenance project. By understanding standard sizes, regional differences, and project-specific requirements, you can confidently specify the ideal scaffolding solution. Always prioritize safety, follow manufacturer guidelines, and conduct regular inspections to maximize the lifespan and reliability of your scaffolding investment. Remember, the right H frame scaffolding standard size is not just about fitting the job-it's about protecting your team, your schedule, and your bottom line.

FAQ

1. What is the most common H frame scaffolding standard size?

The most common standard sizes are 2 m (6.5 ft) in height and 1219 mm (4 ft) in width, though regional standards may vary. Always confirm with your supplier and local regulations.

2. Can H frame scaffolding be customized for special projects?

Yes, many manufacturers offer custom fabrication, including non-standard heights, widths, and heavy-duty frames to meet unique project needs.

3. How high can H frame scaffolding be safely stacked?

H frame scaffolding can be stacked to heights exceeding 12 meters (approximately 40 feet), but always follow manufacturer guidelines and local safety regulations for maximum stacking height.

4. What are the main safety features required for H frame scaffolding?

Essential safety features include guardrails, toe boards, secure locking mechanisms, and regular inspections. Proper training and use of PPE are also critical.

5. How do I calculate the number of H frames needed for my project?

Divide the total height by the frame height (e.g., 6 m / 2 m = 3 frames high), and the total length by the frame width (e.g., 10 m / 1.2 m ≈ 8 bays). Multiply for total frames, and ensure you have enough cross braces and platforms.