Content Menu

● What Are Pressed Scaffolding Couplers?

● Types of Pressed Scaffolding Couplers

● Why Proper Installation Matters

● Tools and Equipment Needed

● Step-by-Step Guide to Installing Pressed Scaffolding Couplers

>> Step 1: Prepare Scaffold Tubes and Couplers

>> Step 2: Position Tubes

>> Step 3: Place the Coupler

>> Step 4: Tighten the Bolt

>> Step 5: Check the Connection

>> Step 6: Repeat for All Connections

● Common Mistakes to Avoid

● Safety Considerations

● Maintenance of Pressed Scaffolding Couplers

● Technical Specifications of Pressed Scaffolding Couplers

● Advantages of Pressed Scaffolding Couplers

● Extended Insights on Installation Techniques

>> Torque Control and Its Importance

>> Alignment and Positioning

>> Use of Proper Tools

● Environmental and Safety Compliance

● Troubleshooting Common Installation Issues

● Conclusion

● FAQ

>> 1. What torque should be used when tightening pressed scaffolding couplers?

>> 2. Can pressed scaffolding couplers be used interchangeably with forged couplers?

>> 3. How often should scaffolding couplers be inspected?

>> 4. What are the signs that a pressed scaffolding coupler needs replacement?

>> 5. Are there safety risks if couplers are not installed properly?

Pressed scaffolding couplers are essential components in tube and coupler scaffolding systems, providing secure and reliable connections between scaffold tubes. Proper installation of pressed scaffolding couplers is critical to ensure the structural integrity, safety, and durability of the scaffold. This comprehensive article covers the types of pressed couplers, step-by-step installation procedures, safety considerations, maintenance tips, and common mistakes to avoid.

What Are Pressed Scaffolding Couplers?

Pressed scaffolding couplers are metal clamps manufactured by pressing high-quality steel sheets into shape. Unlike drop forged couplers, which are forged from heated steel, pressed couplers offer a cost-effective yet robust solution for connecting scaffolding tubes.

Types of Pressed Scaffolding Couplers

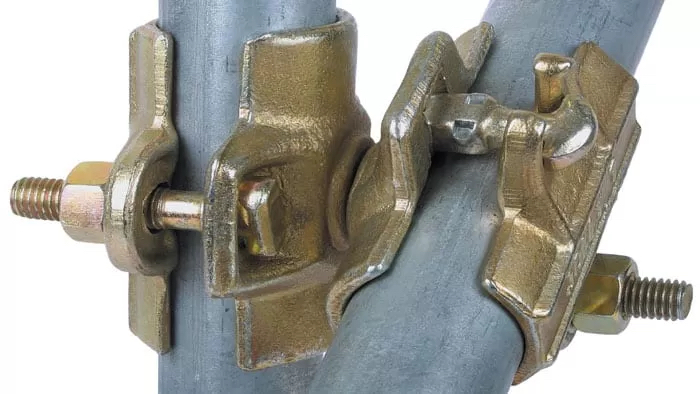

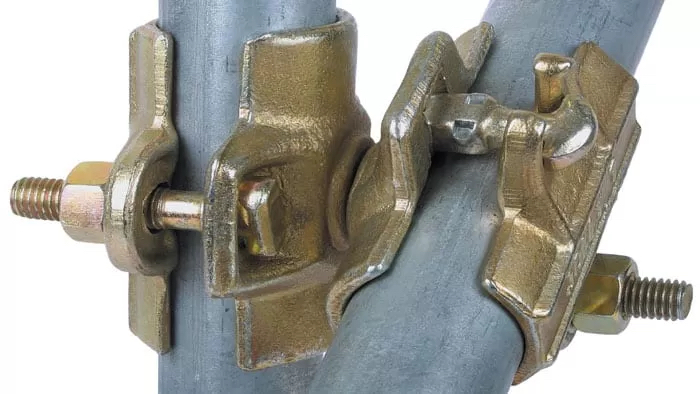

- Right Angle Couplers: Connect two tubes at 90 degrees, forming the main scaffold framework.

- Swivel Couplers: Connect tubes at any angle, useful for diagonal bracing.

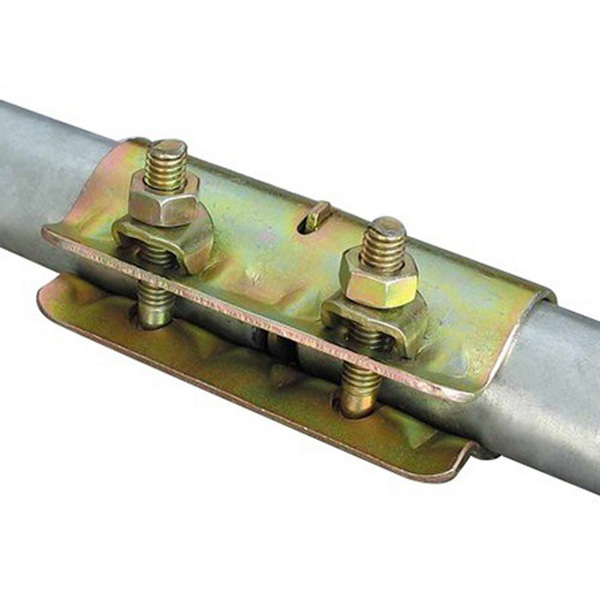

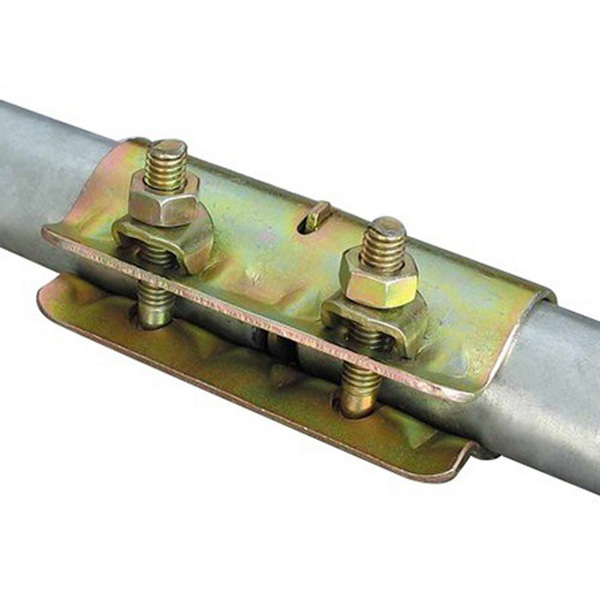

- Sleeve Couplers (Joint Couplers): Join two tubes end-to-end to extend length.

- Putlog Couplers: Attach transoms to ledgers, commonly used in bricklaying scaffolds.

- Girder Couplers: Connect tubes to steel girders or beams.

Why Proper Installation Matters

Proper installation of pressed scaffolding couplers ensures:

- Structural Stability: Secure connections prevent scaffold movement or collapse.

- Load Bearing Capacity: Correct tightening achieves rated load capacities.

- Worker Safety: Reduces risks of accidents from slipping or scaffold failure.

- Compliance: Meets regulatory standards such as BS 1139, EN 74, and OSHA.

- Longevity: Prevents premature wear or damage to couplers and tubes.

Tools and Equipment Needed

- Tube and Coupler Wrench: Typically a 23mm or 24mm spanner or ratchet wrench.

- Torque Wrench: To tighten bolts to manufacturer-recommended torque (usually 45-54 Nm).

- Safety Gloves and Goggles: For personal protection during installation.

- Scaffold Tubes and Couplers: Appropriate sizes and types for the scaffold design.

Step-by-Step Guide to Installing Pressed Scaffolding Couplers

Step 1: Prepare Scaffold Tubes and Couplers

- Inspect tubes and couplers for damage, rust, or dirt.

- Clean surfaces to ensure proper fitting.

- Select the correct coupler type for the connection required.

Step 2: Position Tubes

- Align tubes according to scaffold design, ensuring they meet at the correct angle.

- For right angle couplers, tubes should be perpendicular.

- For swivel couplers, tubes can be at any angle.

Step 3: Place the Coupler

- Open the pressed coupler by loosening the bolt.

- Position the coupler around the tubes, ensuring the pressed steel flaps fit snugly.

- For sleeve couplers, align tubes end-to-end inside the coupler.

Step 4: Tighten the Bolt

- Hand-tighten the bolt initially to hold the coupler in place.

- Use a tube and coupler wrench to tighten further.

- Use a torque wrench to apply the specified torque (usually 45-54 Nm).

- Ensure uniform tightening to avoid uneven stress.

Step 5: Check the Connection

- Verify that the coupler is firmly secured and tubes do not move.

- Ensure no gaps exist between coupler flaps and tubes.

- Confirm the coupler is correctly oriented (e.g., right angle couplers at 90 degrees).

Step 6: Repeat for All Connections

- Follow the same procedure for all coupler connections in the scaffold.

- Use multiple couplers as required for stability.

Common Mistakes to Avoid

- Under-tightening: Leads to loose connections that compromise scaffold stability.

- Over-tightening: Can damage couplers or tubes, reducing lifespan.

- Using Wrong Coupler Type: Each coupler serves a specific purpose; incorrect use weakens the scaffold.

- Ignoring Corrosion: Rust weakens couplers; always inspect and replace damaged parts.

- Mixing Coupler Brands: Different specifications can cause incompatibility and safety risks.

Safety Considerations

- Always wear appropriate PPE during installation.

- Follow manufacturer torque specifications strictly.

- Inspect couplers regularly during scaffold use.

- Replace any damaged or worn couplers immediately.

- Ensure scaffold design complies with local safety regulations.

Maintenance of Pressed Scaffolding Couplers

- Clean couplers after use to remove dirt and debris.

- Apply anti-corrosion coatings or lubricants as needed.

- Store couplers in dry, ventilated areas.

- Perform regular inspections for cracks, corrosion, or deformation.

- Keep an inventory log to track coupler condition and replacement schedules.

Technical Specifications of Pressed Scaffolding Couplers

| Coupler Type | Tube Diameter (mm) | Weight (kg) | Torque (Nm) | Load Capacity (kN) | Finish |

| Right Angle Coupler | 48.3 | 0.8 - 1.0 | 45 - 54 | 6.25 | Hot-dip galvanized |

| Swivel Coupler | 48.3 | 0.9 - 1.1 | 45 - 54 | 6.25 | Zinc plated |

| Sleeve Coupler | 48.3 | 0.9 - 1.0 | 45 - 54 | 6.25 | Hot-dip galvanized |

| Putlog Coupler | 48.3 | 0.6 - 0.7 | 45 - 54 | 3.5 | Painted or galvanized |

Advantages of Pressed Scaffolding Couplers

- Cost-effective compared to drop forged couplers.

- Lightweight and easy to handle.

- Manufactured to strict quality standards.

- Suitable for a wide range of scaffolding applications.

- Corrosion-resistant finishes enhance durability.

Extended Insights on Installation Techniques

Torque Control and Its Importance

Using a torque wrench ensures that couplers are tightened to the precise torque recommended by manufacturers, usually between 45 and 54 Nm. This prevents under-tightening, which can cause slippage, and over-tightening, which can damage the coupler or tube.

Alignment and Positioning

Correct alignment of tubes before tightening couplers is vital. Misaligned tubes can introduce stress points and reduce scaffold stability. Swivel couplers offer flexibility in angles but must be carefully positioned to maintain scaffold integrity.

Use of Proper Tools

While hand tools can be used for initial tightening, specialized tube and coupler wrenches and torque wrenches are recommended for final adjustments to ensure safety and compliance.

Environmental and Safety Compliance

Pressed scaffolding couplers must comply with international standards such as BS 1139, EN 74, and OSHA regulations. These standards specify material quality, load capacity, and testing requirements, ensuring couplers perform safely under expected loads and environmental conditions.

Troubleshooting Common Installation Issues

| Issue | Cause | Solution |

| Coupler slips after tightening | Insufficient torque or damaged threads | Retighten with torque wrench; replace damaged coupler |

| Difficulty tightening bolt | Corrosion or debris in threads | Clean threads; apply lubricant |

| Misaligned tubes | Incorrect positioning | Realign tubes before tightening |

| Bolt or nut damage | Over-tightening or wear | Replace damaged components |

Conclusion

Proper installation of pressed scaffolding couplers is fundamental to building safe, stable, and reliable scaffolding structures. Following manufacturer guidelines, using the correct tools, and adhering to torque specifications ensure that couplers perform effectively under load. Regular inspection and maintenance extend the lifespan of couplers and maintain scaffold safety. By avoiding common mistakes and prioritizing safety, construction professionals can optimize scaffold assembly and protect workers on site.

FAQ

1. What torque should be used when tightening pressed scaffolding couplers?

Typically, a torque of 45 to 54 Nm is recommended to ensure secure fastening without damaging the coupler or tubes.

2. Can pressed scaffolding couplers be used interchangeably with forged couplers?

While both serve similar purposes, forged couplers generally offer higher strength and durability. Pressed couplers are suitable for many applications but check project requirements.

3. How often should scaffolding couplers be inspected?

Couplers should be inspected before each use, periodically during use, and after any incident that may affect structural integrity.

4. What are the signs that a pressed scaffolding coupler needs replacement?

Look for visible cracks, corrosion, deformation, stripped threads, or difficulty in tightening bolts.

5. Are there safety risks if couplers are not installed properly?

Yes, improper installation can lead to scaffold instability, increasing the risk of collapse and worker injury.