Content Menu

● Introduction to Crab Scaffolding Systems

● Key Components of the Crab Scaffolding System

● How Crab Scaffolding Systems Enhance Efficiency

● Applications of Crab Scaffolding Systems

● Case Studies: Real-World Efficiency Gains

>> Case Study 1: High-Rise Building Construction

>> Case Study 2: Bridge Construction

● Best Practices for Maximizing Efficiency

● Potential Challenges and Mitigation Strategies

● Conclusion

● FAQ

>> 1. What is a Crab Scaffolding System?

>> 2. How does the Crab Scaffolding System enhance construction site efficiency?

>> 3. What types of projects are suitable for the Crab Scaffolding System?

>> 4. Is the Crab Scaffolding System safe to use?

>> 5. What are the key benefits of using a Crab Scaffolding System?

● Citations:

Scaffolding is an indispensable component of modern construction, providing temporary structures for supporting workers and materials at height. The choice of scaffolding system significantly impacts project timelines, labor costs, and overall efficiency. Among the various types available, the Crab Scaffolding System stands out as a modern and efficient solution designed to enhance construction site productivity. This article delves into the features, benefits, and applications of the Crab Scaffolding System, illustrating how it contributes to improved efficiency in construction projects.

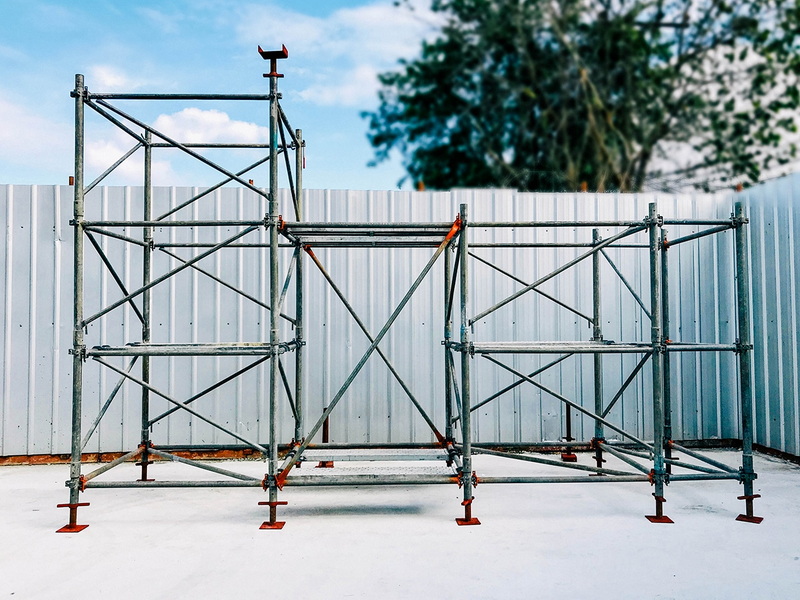

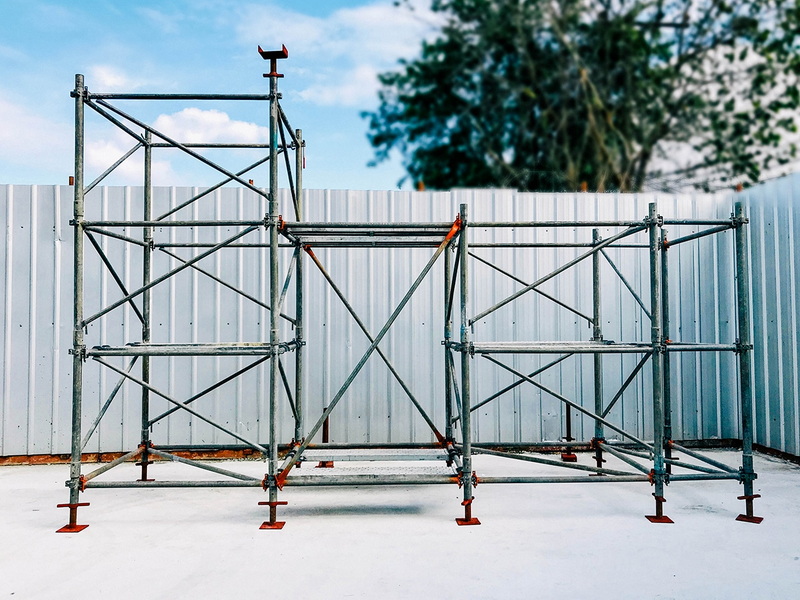

Introduction to Crab Scaffolding Systems

The Crab Scaffolding System, also known as the C60 Scaffolding System, is a modular scaffolding solution renowned for its rapid assembly, high load-bearing capacity, and versatility[1][3]. Developed to meet the demands of heavy-duty construction projects, such as bridges, tunnels, and high-rise buildings, this system employs a unique locking mechanism that resembles a crab's claw, hence the name[3]. This mechanism allows for quick and secure connections between components, minimizing the need for complex tools and reducing assembly time[3]. The Crab Scaffolding System is engineered to provide a safe, stable, and efficient working platform, contributing to enhanced productivity on construction sites[3].

Key Components of the Crab Scaffolding System

Understanding the key components of the Crab Scaffolding System is crucial for appreciating its efficiency-enhancing capabilities. These components work together seamlessly to create a robust and adaptable scaffolding structure[3].

1. Vertical Standards: These are the primary load-bearing supports of the system. Available in various lengths, they provide vertical support for the entire scaffolding structure, ensuring stability even under heavy loads[3]. Made from high-grade steel, these standards are designed to withstand harsh environmental conditions and heavy use[3].

2. Horizontal Ledgers: These components connect vertical standards horizontally, distributing loads evenly across the structure[3]. They provide structural balance and support for work platforms or formwork systems, enhancing the safety and reliability of the scaffolding[3].

3. Diagonal Braces: These provide lateral stability to the scaffolding, preventing structural shifts and ensuring the system remains rigid[3]. Diagonal braces are essential for maintaining the integrity of the structure, particularly in high-load applications[3].

4. Crab Clamps: The unique locking mechanisms that give the system its name. These clamps allow for quick and secure connections between vertical standards and horizontal ledgers, significantly reducing assembly and disassembly time[3].

5. Base Jacks: Adjustable supports used to stabilize the scaffolding on uneven terrain[3]. Base jacks ensure the scaffolding is level and secure, providing a stable base for workers and materials[3].

6. Triangle Frames: These components provide additional stability and support in heavy-duty applications[3]. Their triangular design ensures excellent load distribution and rigidity, making them ideal for high-load scenarios such as bridge decks and large formwork systems[3].

7. U-Heads (Top Heads): Installed on top of vertical standards to support formwork beams[3]. These components are vital for distributing loads from concrete structures evenly, making them indispensable in bridge and slab construction projects[3].

8. Decking and Platforms: These offer safe and sturdy work surfaces for workers[3]. Designed to withstand heavy loads, the decking and platforms provide a secure environment for carrying out construction tasks[3].

How Crab Scaffolding Systems Enhance Efficiency

The Crab Scaffolding System enhances construction site efficiency through several key features and benefits:

1. Rapid Assembly and Disassembly: The crab clamp mechanism allows for quick and secure connections between components, eliminating the need for complex tools[3]. This significantly reduces the time required for assembly and disassembly, saving labor costs and accelerating project timelines[3].

2. High Load-Bearing Capacity: Designed for heavy-duty applications, the Crab Scaffolding System can handle substantial loads, making it suitable for supporting concrete formworks, heavy machinery, and large spans[3]. This ensures workers can carry out their tasks safely and efficiently, without concerns about the stability of the scaffolding[3].

3. Versatility and Adaptability: The modular design of the Crab Scaffolding System allows it to be easily adapted to various construction scenarios[3]. Whether it's a bridge, high-rise building, tunnel, or industrial plant, the system can be configured to meet the specific requirements of the project[3].

4. Enhanced Safety: The sturdy design and secure locking mechanisms of the Crab Scaffolding System minimize the risk of collapse, ensuring worker safety during construction[1]. This reduces the potential for accidents and injuries, contributing to a more productive and efficient work environment[1].

5. Reduced Labor Costs: The ease of assembly and disassembly translates to reduced labor costs on construction projects[1]. With fewer workers needed for scaffolding setup and dismantling, contractors can allocate resources more efficiently[1].

6. Compliance with Standards: The Crab Scaffolding System is designed to comply with international standards such as British Standard BS 5975 and BSEN 12812, guaranteeing top-notch safety and performance[6][7]. This compliance provides peace of mind to construction professionals, knowing they are using a reliable and certified system[7].

Applications of Crab Scaffolding Systems

The Crab Scaffolding System is highly versatile and can be applied to a wide range of construction projects:

- Bridge Construction: Provides a stable base for supporting large concrete formworks, ensuring the safe and efficient construction of bridge structures[3].

- High-Rise Buildings: Ensures safe and reliable scaffolding for tall structures, allowing workers to carry out tasks at height with confidence[3].

- Tunnels and Special Projects: Handles unique structures like chimneys or industrial plants, providing a customizable scaffolding solution for complex construction needs[3].

- Infrastructure Projects: Suitable for various infrastructure projects, including highways, railways, and public works, offering a durable and efficient scaffolding solution[5].

- Heavy Concrete Shuttering Support: Provides robust support for heavy concrete shuttering, ensuring the stability and integrity of concrete structures during the curing process[5].

Case Studies: Real-World Efficiency Gains

To further illustrate the efficiency gains achieved through the use of Crab Scaffolding Systems, let's consider a few hypothetical case studies:

Case Study 1: High-Rise Building Construction

A construction company undertaking the construction of a 40-story high-rise building chose to use the Crab Scaffolding System instead of traditional scaffolding methods. The rapid assembly and disassembly features of the system allowed the company to reduce scaffolding setup time by 30%, resulting in significant labor cost savings. The high load-bearing capacity of the system also ensured workers could safely and efficiently carry out tasks at height, contributing to an overall project timeline reduction of 15%.

Case Study 2: Bridge Construction

A civil engineering firm tasked with constructing a large bridge utilized the Crab Scaffolding System to support the concrete formworks. The versatility of the system allowed the firm to adapt the scaffolding to the complex geometry of the bridge design. The stable and secure working platform provided by the Crab Scaffolding System enhanced worker safety and productivity, leading to a successful and timely completion of the project.

Best Practices for Maximizing Efficiency

To maximize the efficiency gains from using the Crab Scaffolding System, consider the following best practices:

- Proper Planning: Develop a detailed scaffolding plan that considers the specific requirements of the construction project.

- Component Selection: Choose the right Crab Scaffolding System components for the project, ensuring they can handle the anticipated weight of workers, materials, and equipment[1].

- Thorough Training: Provide comprehensive training to all workers on the assembly, use, and safety procedures of the Crab Scaffolding System[1].

- Regular Inspections: Conduct regular inspections of the scaffolding to ensure all components are in good working condition[1].

- Maintenance: Maintain the scaffolding system properly, replacing any damaged or worn components promptly[1].

- Compliance: Ensure the Crab Scaffolding System complies with all relevant safety standards and regulations[7].

- Coordination: Coordinate scaffolding activities with other construction tasks to minimize disruptions and maximize efficiency[1].

Potential Challenges and Mitigation Strategies

While the Crab Scaffolding System offers numerous efficiency benefits, it's important to be aware of potential challenges and have strategies in place to mitigate them:

Initial Investment:

- Challenge: The initial cost of purchasing a Crab Scaffolding System may be higher than traditional scaffolding methods.

- Mitigation: Consider the long-term cost savings from reduced labor costs and increased productivity, which can offset the initial investment over time[1].

Training Requirements:

- Challenge: Workers may require specialized training to properly assemble and use the Crab Scaffolding System[1].

- Mitigation: Invest in comprehensive training programs to ensure workers are competent in the safe and efficient use of the system[1].

Component Management:

- Challenge: Managing and tracking the various components of the modular system can be complex.

- Mitigation: Implement a robust inventory management system to track components, prevent loss, and ensure the right parts are available when needed.

Site Conditions:

- Challenge: Uneven or unstable ground conditions can pose challenges for scaffolding setup.

- Mitigation: Use base jacks and other adjustable supports to stabilize the scaffolding on uneven terrain[3]. Ensure the ground is properly compacted and leveled before setting up the system.

Conclusion

The Crab Scaffolding System is a highly efficient and versatile solution that enhances construction site productivity through its rapid assembly, high load-bearing capacity, and adaptability. By understanding its components, following best practices, and addressing potential challenges, construction professionals can maximize the benefits of this system and achieve significant efficiency gains. The Crab Scaffolding System not only improves project timelines and reduces labor costs but also ensures a safer working environment, making it an indispensable tool for modern construction projects.

FAQ

1. What is a Crab Scaffolding System?

The Crab Scaffolding System, also known as the C60 Scaffolding System, is a modular scaffolding solution known for its rapid assembly, high load-bearing capacity, and versatility[3]. It employs a unique locking mechanism that resembles a crab's claw, allowing for quick and secure connections between components[3].

2. How does the Crab Scaffolding System enhance construction site efficiency?

The Crab Scaffolding System enhances efficiency through its rapid assembly and disassembly, high load-bearing capacity, versatility, enhanced safety, and reduced labor costs[1][3]. The crab clamp mechanism allows for quick connections, and the modular design allows it to adapt to various construction scenarios[3].

3. What types of projects are suitable for the Crab Scaffolding System?

The Crab Scaffolding System is suitable for a wide range of construction projects, including bridge construction, high-rise buildings, tunnels, infrastructure projects, and heavy concrete shuttering support[3][5].

4. Is the Crab Scaffolding System safe to use?

Yes, the Crab Scaffolding System is designed with safety in mind. Its sturdy design and secure locking mechanisms minimize the risk of collapse, ensuring worker safety during construction[1][3]. The system also complies with international safety standards[7].

5. What are the key benefits of using a Crab Scaffolding System?

The key benefits of using a Crab Scaffolding System include rapid assembly and disassembly, high load-bearing capacity, versatility, enhanced safety, reduced labor costs, and compliance with safety standards[1][3][7].

Citations:

[1] https://fishery.fnb.tech/crab-system-a-deep-dive-into-its-applications/

[2] https://www.hklscaffolding.com.sg/category/c60-crab-system/

[3] https://rapidsea.sg/c60-scaffolding/

[4] https://www.hklscaffolding.com.sg/elementor-7036/

[5] https://www.wm-scaffold.com/crab-60-shoring-system.html

[6] https://rapid-scafform.com/c60-shoring-system/

[7] https://jumplyscaffolding.com/c60-scaffolding/

[8] https://plytec.com.my/build-smarter-with-wonder-crab-lock-the-modular-shoring-revolution/