Content Menu

● What is a Pump Jack Scaffolding System?

● Benefits of Using a Pump Jack Scaffolding System

● How Pump Jack Scaffolding Works

● Applications of Pump Jack Scaffolding

● Safety Considerations

● Detailed Components of Pump Jack Scaffolding

>> Pump Jacks

>> Vertical Poles

>> Work Platform

>> Safety Features

● Comparative Analysis with Other Scaffolding Systems

● Advantages of Using a Pump Jack Scaffolding System

● Conclusion

● FAQ

>> 1. What is a pump jack scaffolding system?

>> 2. How does a pump jack scaffolding system improve efficiency?

>> 3. What are the main components of a pump jack scaffolding system?

>> 4. What types of projects benefit from using pump jack scaffolding?

>> 5. What safety precautions should be taken when using a pump jack system?

● Citations:

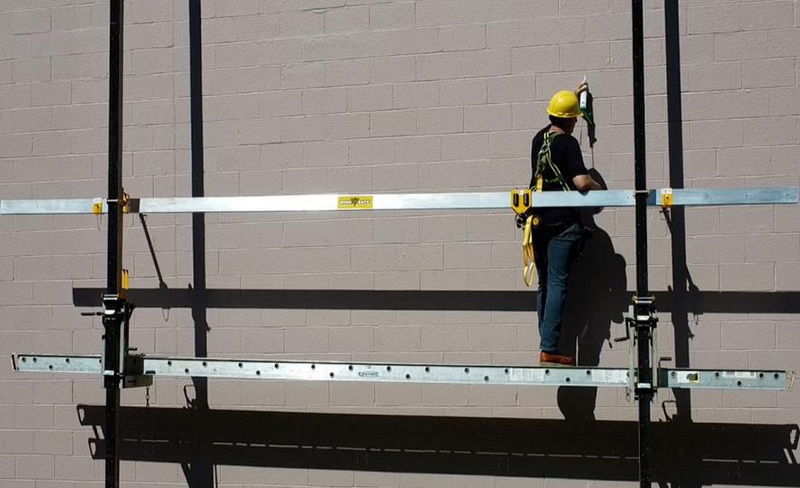

In the construction industry, efficiency is paramount. One of the most effective tools that enhance worksite productivity is the pump jack scaffolding system. This innovative scaffolding solution is designed to provide workers with a safe and adjustable platform that can be easily raised or lowered, making it ideal for a variety of tasks. In this article, we will explore how the pump jack scaffolding system improves worksite efficiency, its components, benefits, applications, and safety considerations.

What is a Pump Jack Scaffolding System?

A pump jack scaffolding system consists of several key components that work together to create a stable and adjustable working platform. The primary elements include:

- Pump Jacks: These are mechanical devices that allow for vertical movement of the platform. Workers can raise or lower the platform with minimal effort using a foot-operated pump mechanism.

- Vertical Poles: These provide structural support for the pump jacks and the platform. They are typically made from lightweight materials such as aluminum or steel.

- Scaffolding Platform: This is where workers stand while performing tasks. It is designed to be sturdy and wide enough to accommodate tools and materials.

- Braces and Safety Features: These components ensure stability and safety during use, preventing falls and maintaining structural integrity.

Benefits of Using a Pump Jack Scaffolding System

The pump jack scaffolding system offers numerous advantages that contribute to improved worksite efficiency:

- Adjustable Height: The ability to easily adjust the height of the platform allows workers to access different levels without needing to disassemble and reassemble the scaffolding. This adaptability is particularly beneficial for tasks such as siding installation, painting, and roof repairs.

- Quick Setup and Dismantling: The straightforward design of pump jack scaffolding enables quick assembly and disassembly, reducing downtime on job sites. This efficiency is crucial for projects with tight schedules.

- Cost-Effective Solution: Compared to more complex scaffolding systems, pump jack scaffolding is often more affordable. Its simplicity makes it an ideal choice for smaller-scale projects or maintenance tasks.

- Portability: The lightweight nature of pump jack systems makes them easy to transport between job sites. This flexibility enhances workflow and adaptability on construction projects.

How Pump Jack Scaffolding Works

The operation of a pump jack scaffolding system is relatively simple:

1. Setup: The vertical poles are anchored securely to the ground or structure. The pump jacks are then attached to these poles at the desired height.

2. Adjusting Height: Workers can raise or lower the platform by using the foot-operated pump mechanism on each jack. This allows for precise height adjustments as needed throughout the project.

3. Safety Features: As the platform is raised or lowered, safety brackets lock into place to prevent accidental drops. Guardrails provide additional protection against falls.

Applications of Pump Jack Scaffolding

The versatility of pump jack scaffolding makes it suitable for various construction tasks, including:

- Siding Installation: The adjustable height feature allows workers to easily reach different areas of a building's exterior.

- Exterior Painting: Painters can quickly adapt the platform's height to access various levels without needing multiple ladders or scaffolds.

- Window Installation and Repair: For jobs like window installation or repair, pump jack scaffold offers a flexible, adjustable platform to accommodate different window heights.

- Roofing Work: While primarily used for low-rise structures, pump jacks can assist with roofing tasks by providing stable access for gutter installation or repairs.

Safety Considerations

Safety is a critical aspect when using any scaffolding system, including pump jacks:

- Regular Inspections: Before use, it's essential to inspect all components for signs of wear or damage. Ensure that all connections are secure and that safety features are functioning properly.

- Proper Training: Workers should receive training on how to safely operate pump jack systems, including setup procedures and weight limits.

- Adherence to Regulations: Always follow local safety regulations and guidelines when using pump jack scaffolding. OSHA standards may require additional safety measures when working at certain heights.

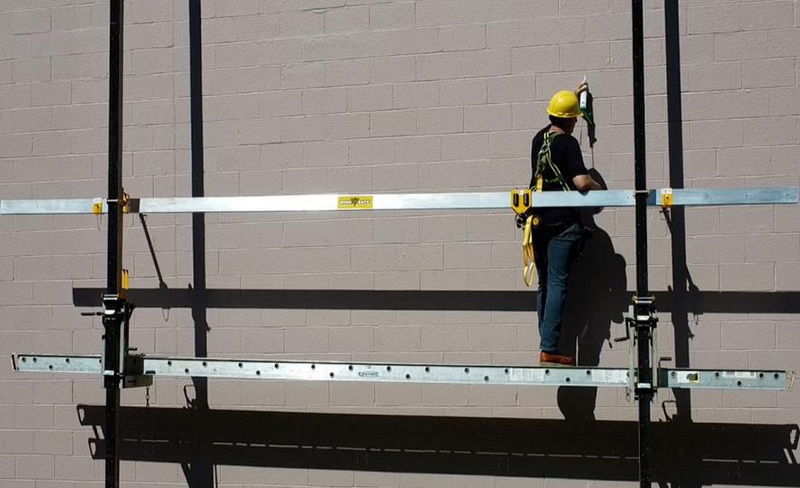

Detailed Components of Pump Jack Scaffolding

To fully understand how a pump jack scaffolding system works, it's essential to delve deeper into its individual components:

Pump Jacks

The heart of any pump jack system is its jacks themselves. These devices utilize a unique mechanism that allows workers to elevate their working platform effortlessly.

- Mechanism Types: There are generally two types of mechanisms used in pump jacks—manual foot-pump systems and hydraulic systems. Manual systems require physical effort from workers, while hydraulic systems offer smoother operation with less physical strain.

Vertical Poles

The vertical poles serve as the backbone of the scaffold structure:

- Material Choices: Typically made from either aluminum or steel, these poles must be lightweight yet durable enough to support significant weight loads without bending or breaking.

- Height Adjustability: Most vertical poles come in various lengths, allowing them to be adjusted according to specific job requirements while ensuring stability at all times.

Work Platform

The work platform must be robust enough to support both workers and their tools:

- Platform Design: Platforms can be made from wood or metal materials depending on project needs. They should have a minimum width (often around 12 inches) for safety purposes while providing ample space for movement.

Safety Features

Safety cannot be overlooked when discussing any type of scaffolding:

- Guardrails and Toe Boards: Guardrails are essential when working at heights over 10 feet (3 meters) to prevent falls. Toe boards prevent tools or materials from falling off the edge of the platform.

Comparative Analysis with Other Scaffolding Systems

Understanding how pump jack scaffolding compares with other systems can highlight its unique advantages:

| Feature | Pump Jack Scaffolding | Traditional Frame Scaffolding | Suspended Scaffolding |

| Ease of Setup | Quick | Time-consuming | Moderate |

| Portability | High | Moderate | Low |

| Height Adjustability | Excellent | Limited | Excellent |

| Cost | Low | Moderate | High |

| Stability | Good | Excellent | Variable |

Advantages of Using a Pump Jack Scaffolding System

There are several advantages to using a pump jack system:

- Ease of Use: The manual or hydraulic operation makes it simple to adjust the platform's height with little effort.

- Portability: The system is relatively lightweight, easy to transport, and requires minimal assembly.

- Cost-Effective: For smaller projects, a pump jack system can be more affordable than renting or building larger scaffolding setups.

- Safety Features: When used correctly, the safety features of pump jacks provide reliable fall protection and stability.

Conclusion

The pump jack scaffolding system significantly enhances worksite efficiency by providing a safe, adjustable, and cost-effective solution for various construction tasks. Its ease of use, quick setup, and versatility make it an invaluable tool for contractors and workers alike. By prioritizing safety and adhering to best practices, construction teams can maximize the benefits of this innovative scaffolding system while ensuring worker safety at all times.

FAQ

1. What is a pump jack scaffolding system?

A pump jack scaffolding system is an adjustable scaffolding solution that allows workers to raise or lower a platform easily using mechanical pump jacks attached to vertical poles.

2. How does a pump jack scaffolding system improve efficiency?

It improves efficiency by allowing quick height adjustments without disassembly, enabling faster setup times, reducing labor costs, and providing a stable working platform for various tasks.

3. What are the main components of a pump jack scaffolding system?

The main components include pump jacks for vertical movement, vertical poles for support, a sturdy work platform, braces for stability, and safety features like guardrails.

4. What types of projects benefit from using pump jack scaffolding?

Pump jack scaffolding is ideal for residential construction projects such as siding installation, exterior painting, window repairs, and roofing work on low-rise structures.

5. What safety precautions should be taken when using a pump jack system?

Safety precautions include regular inspections of equipment, proper training for users, adherence to local regulations, and ensuring all safety features are functional before use.

Citations:

[1] https://safetyeducations.com/pump-jack-scaffolding/

[2] https://www.associated-scaffolding.com/news/pump-jacks

[3] https://falconladder.com/pump-jack/

[4] https://www.pitb.com/pump-jack-scaffolding-requirements/

[5] https://scaffoldingrentalandsales.com/blog/what-is-a-scaffolding-pump-jack-and-how-does-it-work/

[6] https://scaffoldtype.com/pump-jack-scaffolding-2/

[7] http://www.osha.gov/etools/scaffolding/supported/pump-jack

[8] https://dss.net/guide-to-pump-jack-scaffolding-types-pros-and-cons/

[9] https://patents.google.com/patent/US20050263350A1/en

[10] https://www.badgerladder.com/pdfs/titan-safety-instructions.pdf